Tin soldering device applied to production of computer circuit board

A technology for circuit boards and computers, which is applied in the field of soldering devices for computer circuit board production, can solve the problems of inconvenient cleaning of filter mechanisms, and achieve the effects of convenient replacement, guaranteed sealing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

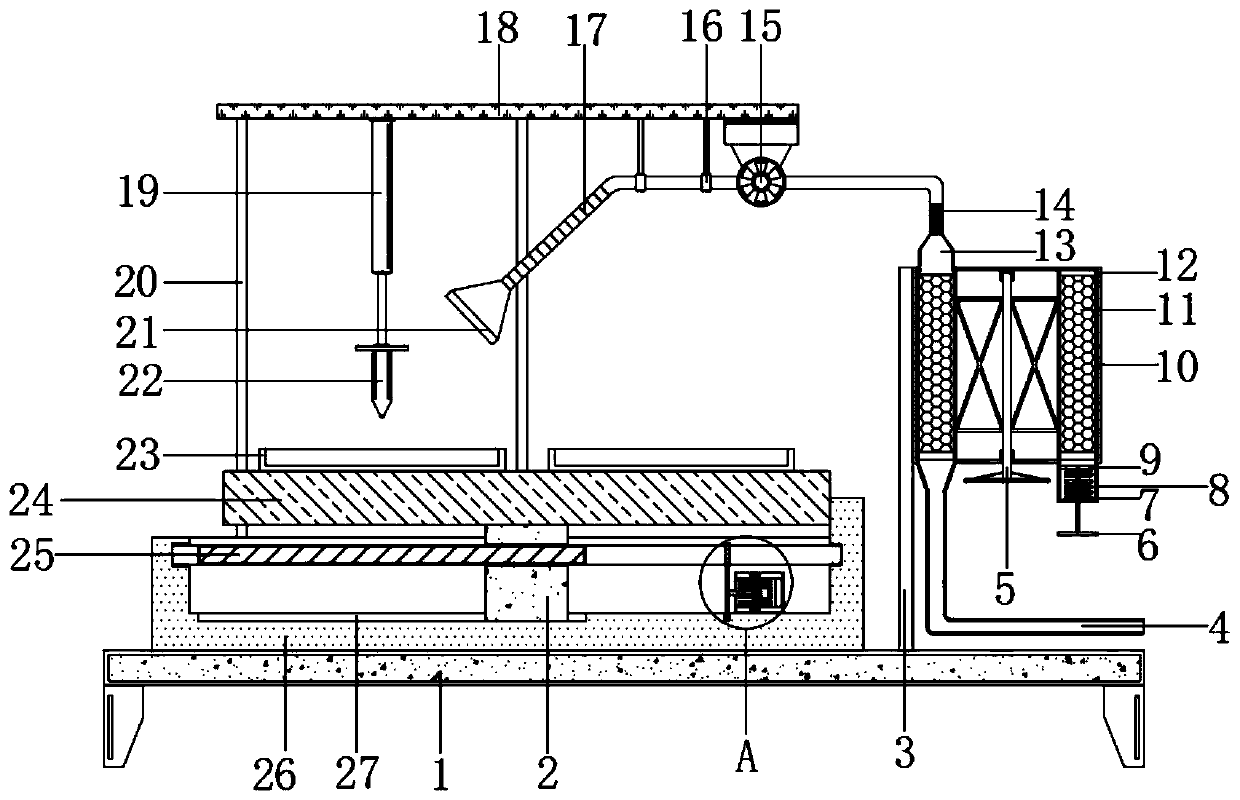

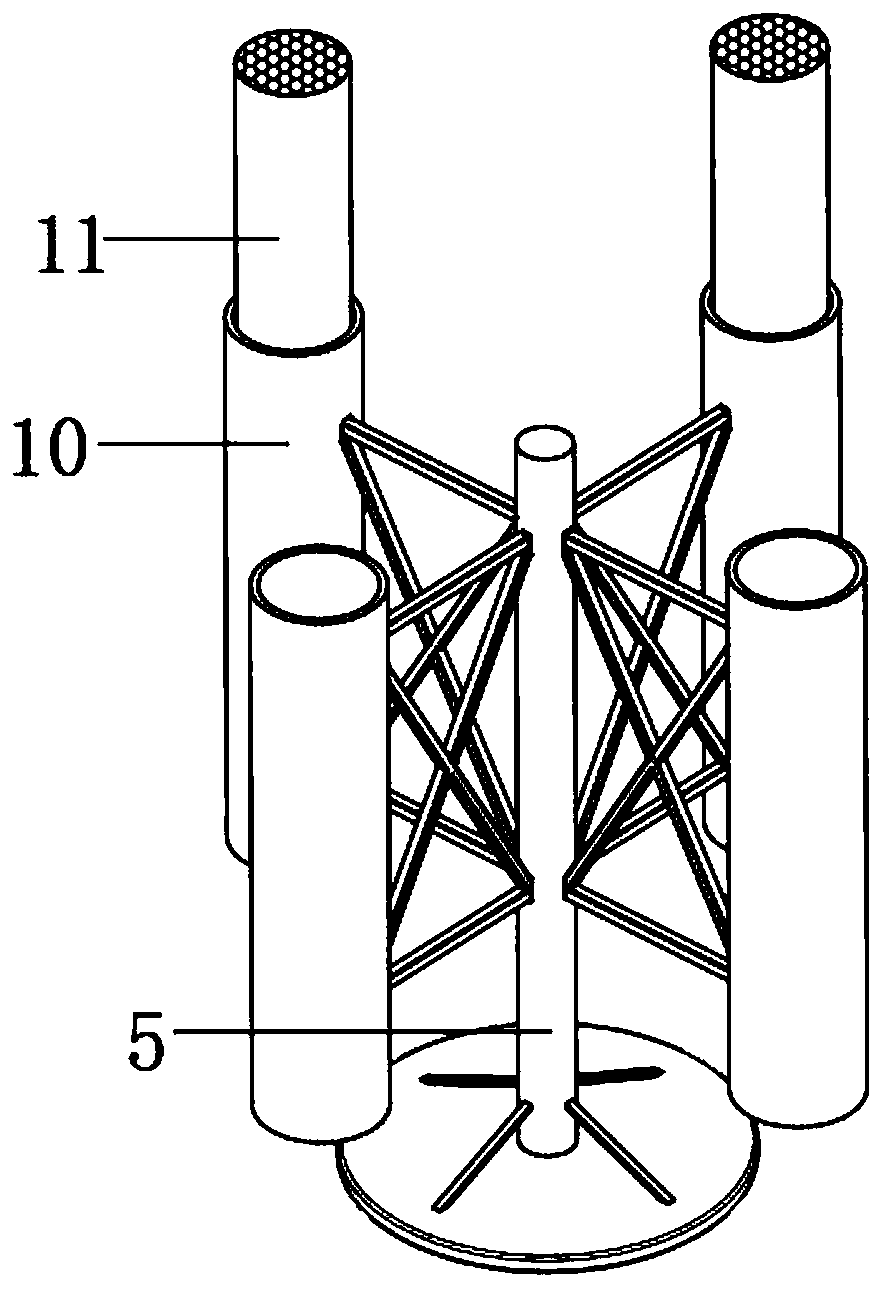

[0030] refer to Figure 1-5 , a soldering device for computer circuit board production, comprising a base 1 with legs welded at the four corners of the bottom and a fixed seat 26 fixed to the outer wall of the top of the base 1 by bolts, a mobile bearing mechanism is installed on the top of the fixed seat 26, and the base 1 is close to One side of the fixed seat 26 is welded with a bracket 20, the top of the bracket 20 is welded with a top plate 18, one end of the top outer wall of the base 1 is vertically welded with an arc-shaped mounting plate 3, and the arc-shaped mounting plate 3 and the top plate 18 are installed with a smoke filter Mechanism, the flue gas filter mechanism respectively includes the exhaust fan 15 fixed to the bottom of the top plate 18 by bolts and the filter box 12 welded to the side of the arc-shaped mounting plate 3, and the center of the filter box 12 is connected to the rotary rod 5 through bearing rotation, The outer peripheral wall of the rotating...

Embodiment 2

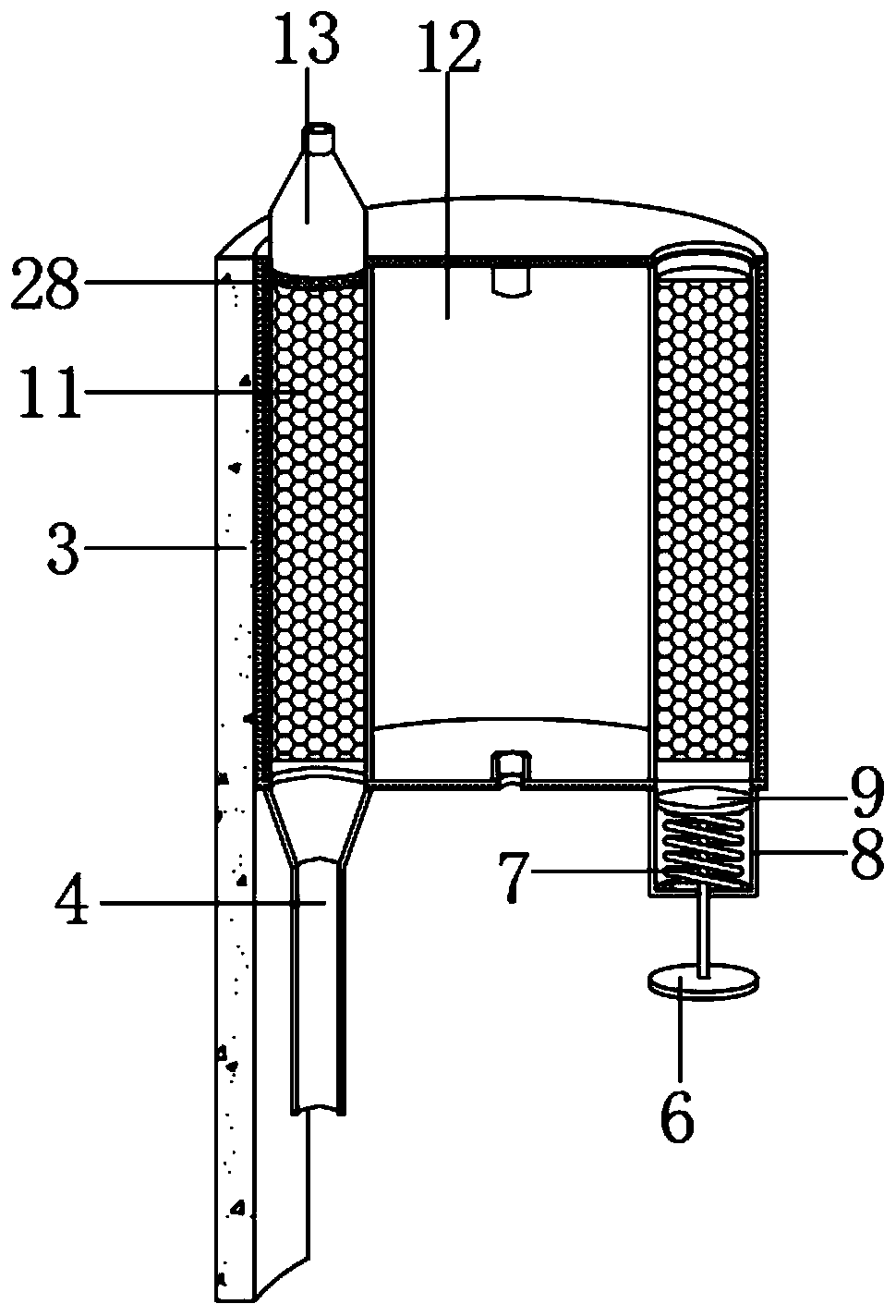

[0041] refer to image 3 , a soldering device for computer circuit board production. Compared with Embodiment 1, this embodiment also includes a rubber sealing ring 28 bonded to the outer wall of the end of the tapered snap joint 13 .

[0042] When the present invention is used: through the setting of the rubber sealing ring 28, the sealing performance when the conical clamping joint 13 is connected with the filter cartridge 10 can be ensured to prevent air leakage, thereby ensuring the treatment effect of the device on welding fume .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com