Coal mine gas extraction device

An extraction device and technology for coal mine gas, applied in the field of coal mine gas extraction devices, can solve the problems of gas waste, easy explosion, and high mine gas content, and achieve the effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

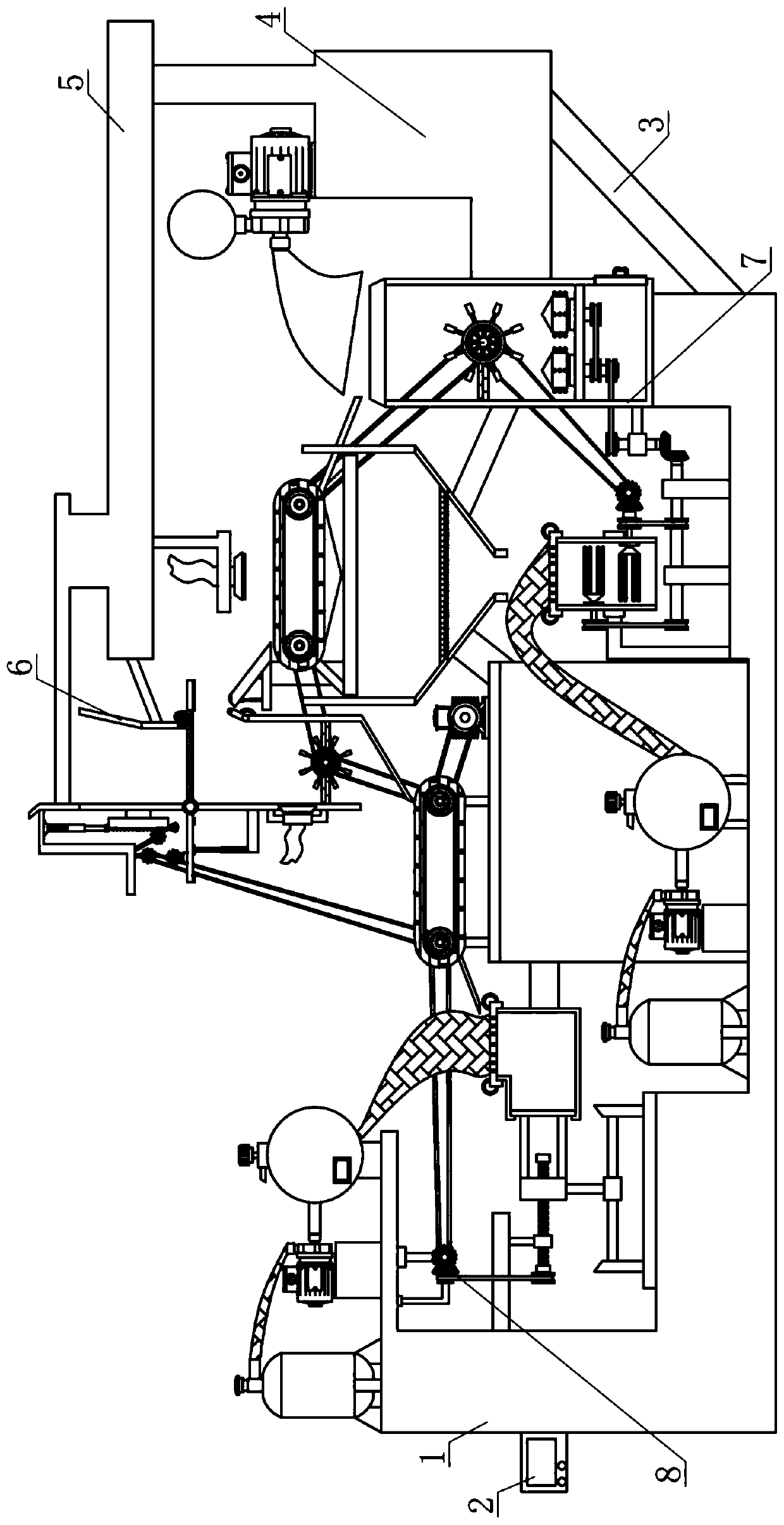

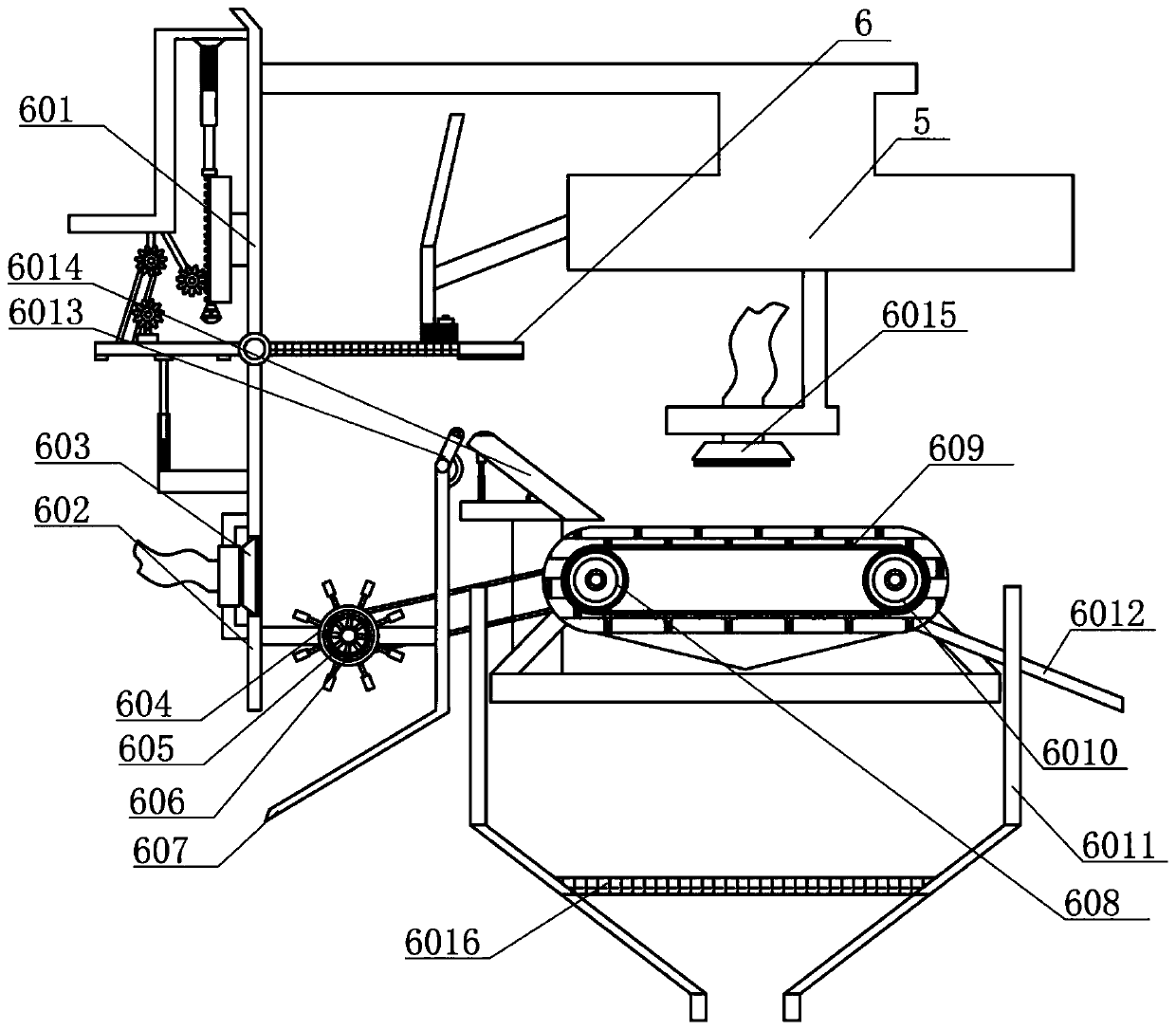

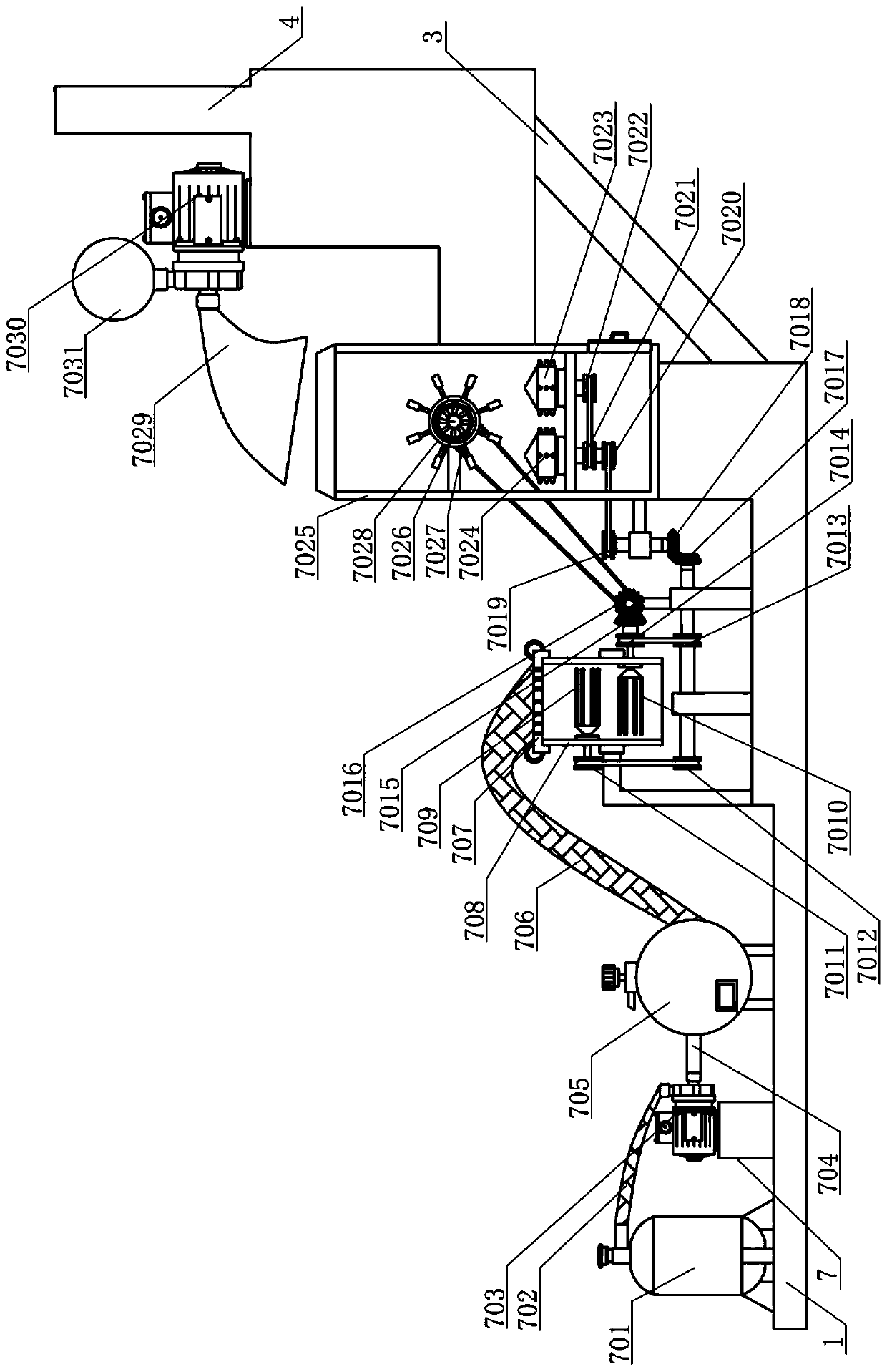

[0024] A coal mine gas extraction device, such as Figure 1-5 As shown, including connecting bottom frame 1, real-time control screen 2, right connecting column 3, right supporting frame 4, top plate 5, coal mine separation and separation mechanism 6, coal combined gas extraction mechanism 7 and coal powder compression extraction mechanism 8. ; The middle of the left end of the connecting bottom frame 1 is provided with a real-time control screen 2; the middle of the right end of the connecting bottom frame 1 is connected with the right connecting column 3; the right side of the connecting bottom frame 1 is provided with a coal block combined gas extraction mechanism 7 and coal blocks are combined The middle of the right end of the gas extraction mechanism 7 is connected with the right connecting column 3; the left side of the connecting bottom frame 1 is provided with a coal powder compression extraction mechanism 8; the right side of the right connecting column 3 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com