Self-resetting prefabricated pier structure for single pile foundation and assembly method thereof

A monopile foundation and prefabricated assembly technology, which is applied in the direction of foundation structure engineering, bridges, sheet pile walls, etc., can solve the problems of repairability and long-term use performance, difficulty in on-site construction, lack of structural forms, etc., and achieve reduction The effect of bridge maintenance work, improvement of construction quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

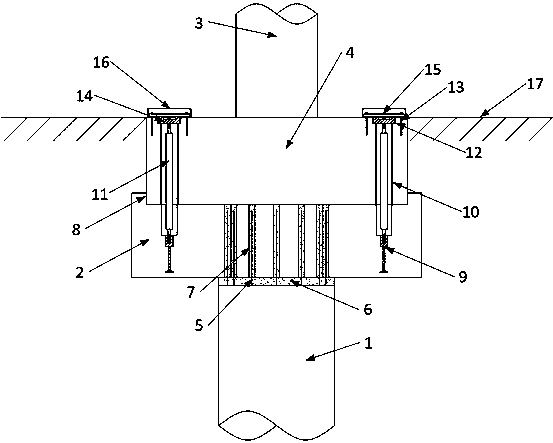

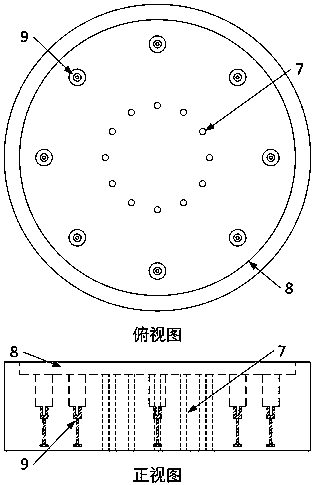

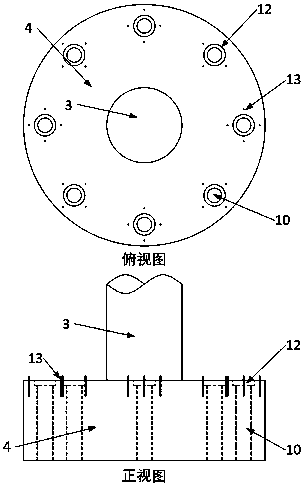

[0035] Self-resetting prefabricated bridge pier structure for monopile foundation, including bored pile foundation 1, prefabricated pile top platform 2 and prefabricated pier 3 with base 4; as figure 2 As shown, a groove 8 is reserved on the top of the prefabricated pile top platform 2, and a long reserved channel 7 made of steel bellows is provided in the middle. The reserved channel 7 is arranged in a ring, and its position is connected to the top of the pile foundation 1 The longitudinal reinforcement 5 is aligned, and the prefabricated pile top platform 2 is also pre-embedded with threaded anchors 9 for energy-dissipating tendons, and the threaded anchors 9 are arranged in a ring on the outer edge of the pile top platform 2; figure 1 As shown, the pile foundation 1 is located under the prefabricated pile top platform 2, and bears the weight of the prefabricated pile top platform 2 and the static and dynamic load of the bridge. Full contact with the prefabricated pile top ...

Embodiment 2

[0040] An assembly method for a self-resetting prefabricated bridge pier structure for a single pile foundation, comprising the following steps:

[0041] Preparation steps: When prefabricating the pile top platform 2 and the pier base 4, the reserved tunnel 1 7, the energy-dissipating tendon thread anchor 9, and the reserved tunnel 2 10 should be arranged in strict accordance with the design plan, and their positions should be confirmed after review. The pile top platform 2 and the bridge pier base 4 should be prefabricated in a matching way to ensure that their contact surfaces match and that the reserved channel 2 10 is aligned with the threaded anchor 9 of the energy-dissipating tendons. The reserved channel-7 should be made of steel bellows, so as to ensure the effective transmission of internal force. The connecting longitudinal reinforcement 5 on the top of the reinforcement cage of the pile foundation should be positioned using a formwork to ensure that it corresponds t...

Embodiment 3

[0050] A repair method for a self-resetting prefabricated bridge pier structure for a monopile foundation, when the base of the pier undergoes rotational displacement under earthquake action:

[0051] S1, open the protective cover 16, remove the fixed steel plate 15 and the circular insert 14, unscrew the yielded energy-dissipating tendon 11 from the energy-dissipating tendon threaded anchor 9 in the pile top platform;

[0052] S2, screw the new energy-dissipating tendon 11 into the energy-dissipating tendon threaded anchor 9, reinstall the circular insert 14 and the fixed steel plate 15, and then install the protective cover 16 to complete the repair work, and the bridge immediately restores its seismic performance.

[0053] The invention has no damage to other parts except the yielding of the energy-dissipating tendons under the action of the earthquake, thereby ensuring the use function of the bridge after the earthquake. The yielded energy-dissipating tendons can be quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com