Spherical array impedance composite muffling structure

An impedance composite, spherical technology, applied in the direction of sound production equipment, noise suppression, household heating, etc., can solve the problems of high energy consumption, contrary to environmental protection, energy saving and emission reduction, and low noise reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

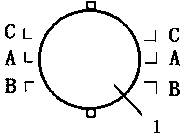

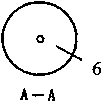

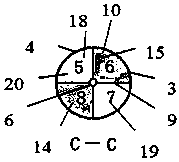

[0027] Such as Figure 1~4 As shown, a spherical array impedance composite noise reduction structure, the diameter of the spherical noise reduction body 1 is determined according to the size of the flow area of the noise reduction channel 2, the diameter of the spherical noise reduction body 1 ~ between, the The spherical muffler 1 includes a perforated plate 3, a micro-perforated plate 4, a partition 5 and a circular tube 6, the partition 5 is circular, and the center of the circular partition 7 is provided with a central opening structure 8. The circular tube 6 penetrates into the hole of the central opening structure 8 of the circular partition 7 and is fixed. The length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com