An experimental method for forced imbibition and flowback of shale fracturing fluid under the condition of adsorbed gas

An experimental method, fracturing fluid technology, applied in permeability/surface area analysis, suspension and porous material analysis, instruments, etc., can solve the problem of failure to fully consider the impact and inability to accurately describe the imbibition and flowback behavior of fracturing fluid. For other problems, to achieve the effect of improving the experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

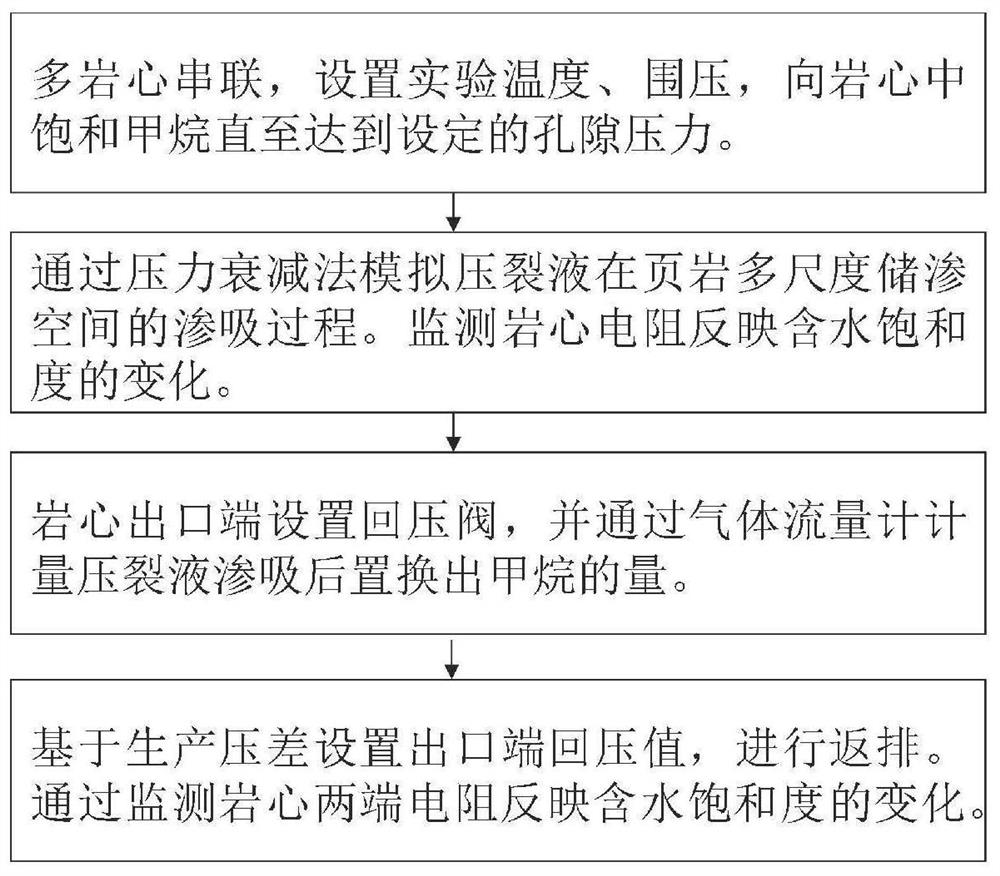

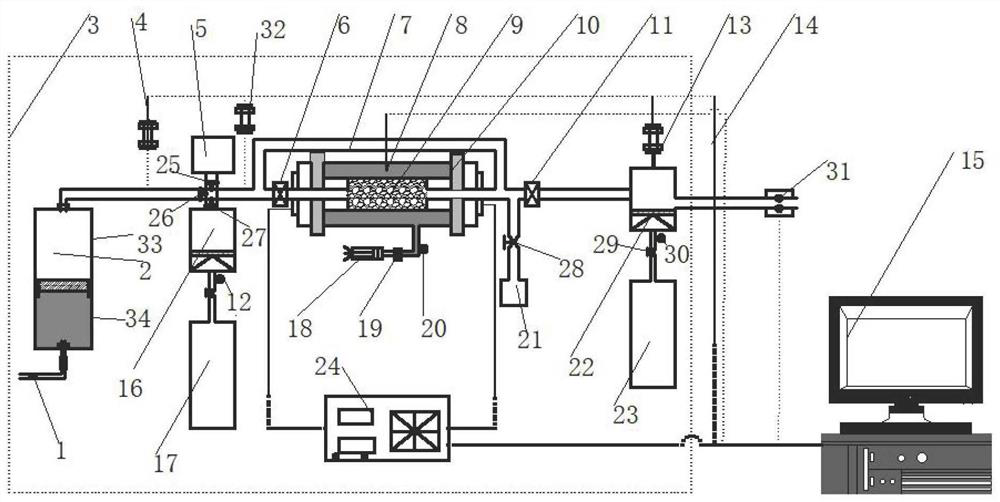

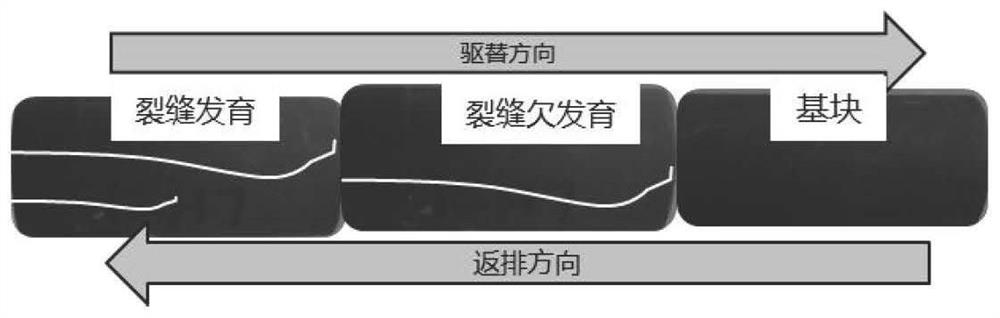

[0071] Such as figure 1 As shown in the present invention, a shale fracturing fluid forced imbibition and flowback experimental method under the condition of containing adsorbed gas, the experimental device adopted includes a gas source, an intermediate container, a long core holder 10, a back pressure valve (16 , 22), control valves (6, 11, 19, 25, 26, 27, 28, 29), pipeline 7, confining pressure pump 18, vacuum pump 21, bridge instrument 24, computer 15, constant temperature system 3; the gas source is The nitrogen source 1, the gas source is connected to the intermediate container, the long core holder 10, the back pressure valve, the gas flow meter 31, and the bridge instrument 24 to the two ends of the long core holder 10 through pipelines, and the long core holder 10 is connected to the long core holder. A confining pressure pump 18 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com