Method and system for eliminating direct-current deviation of ultrasonic echo signal

A technology of DC deviation and signal elimination, which is used in the generation of ultrasonic/sonic/infrasonic waves, the detection of response signals, and the use of sonic/ultrasonic/infrasonic waves for material analysis, etc. problems, to achieve the effect of prolonging the service life, enhancing the signal-to-noise ratio, and eliminating the cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

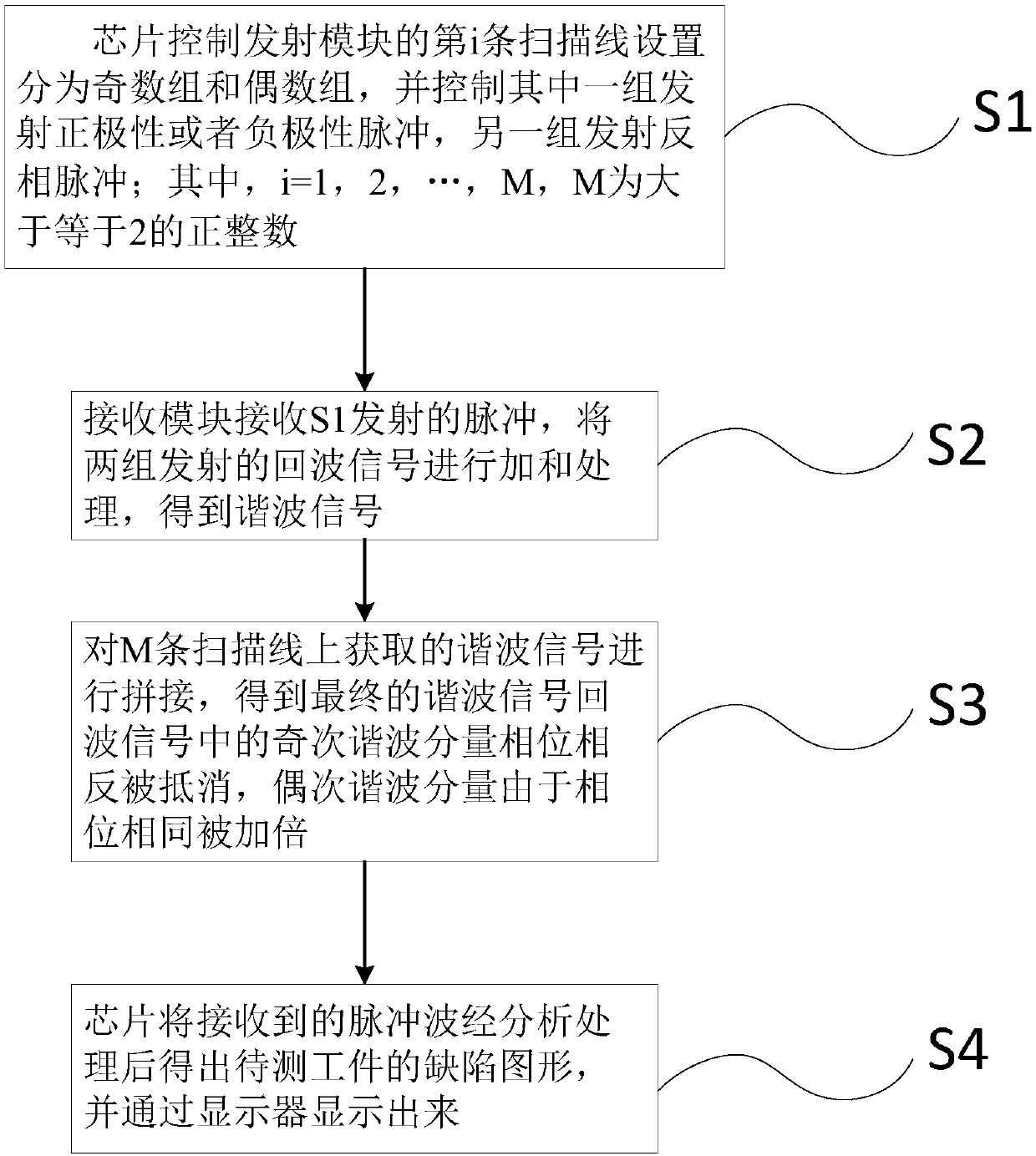

[0027] Such as figure 1 As shown, the present invention is a method for eliminating DC deviation of an ultrasonic echo signal, comprising the following steps:

[0028] S1, the chip controls the emission module to divide the emission of the i-th scanning line into odd groups and even groups, and control one group of emission lines to emit positive or negative polarity pulses, and the other group of emission lines to emit anti-phase pulses, where , i=1, 2, ..., M, M is a positive integer greater than or equal to 2;

[0029] S2, the receiving module receives the pulse transmitted by S1, and adds and processes the echo signals transmitted by the two groups to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com