Angular point detection method based on visible light and infrared universal calibration board

A technology of corner point detection and calibration board, which is applied in image data processing, instrumentation, computing, etc., can solve the problems of feature point extraction, corner point blurring, poor image contrast, etc., and achieve good image contrast, accurate calibration results, and corner point detection. Imaging clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

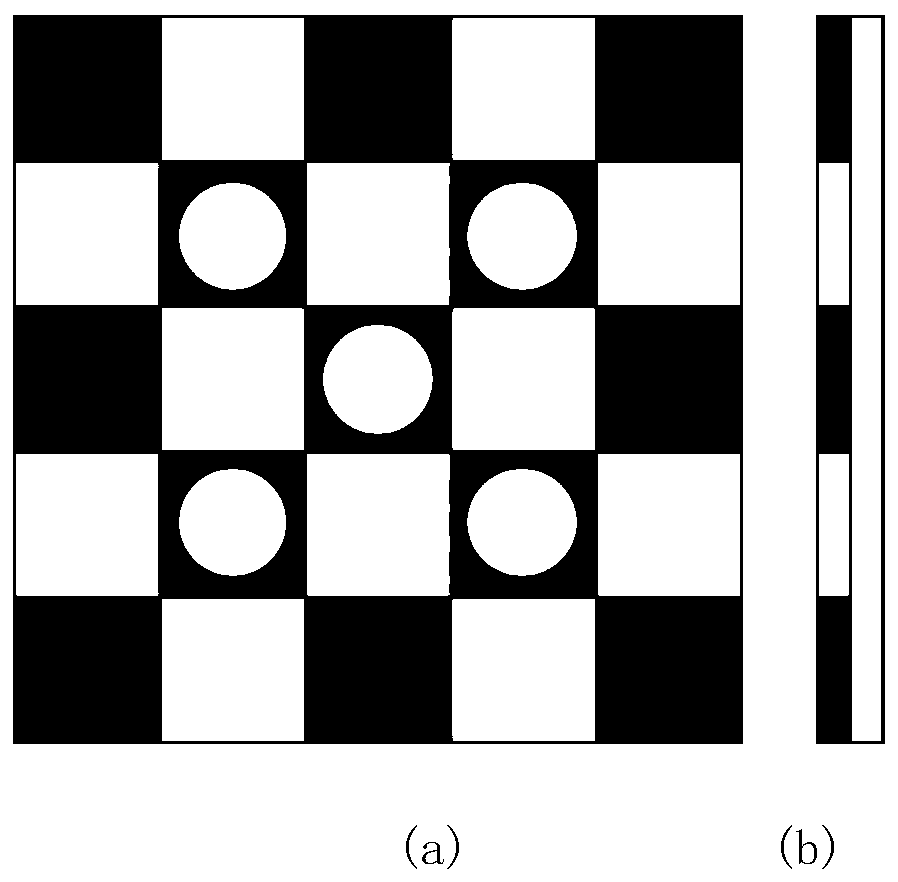

[0029] The invention proposes a calibration board that is common to visible light and infrared cameras. The calibration board is composed of a calibration board bottom plate and two rectangular sheets of different materials. The calibration board is provided with one or several pieces of certain colors or shapes. The purpose of the logo is to determine the world coordinate system of the checkerboard pattern through the logo. The use of two materials to absorb photons in the visible light and infrared spectrum differently ensures that the calibration board can present a clear checkerboard pattern under both the visible light camera and the infrared camera. The following are specific cases:

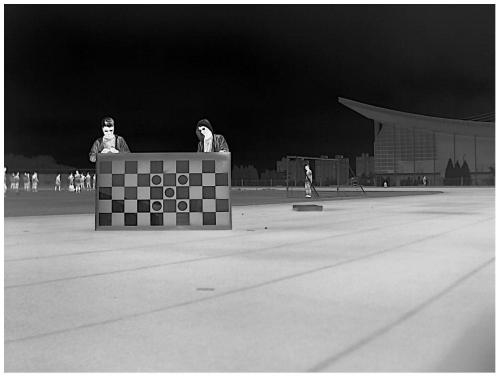

[0030] The infrared camera has a spectral range of 8 to 14 μm, the highly polished aluminum flakes are in the full spectral range, the emissivity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com