Forming method of ePTFE enhanced proton exchange membrane

A technology of proton exchange membrane and forming method, which is applied in the field of membrane material preparation, can solve the problems of uneven thickness of composite membrane and low film forming efficiency, and achieve the effects of dense film structure, low overcoming efficiency and rapid film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare a perfluorosulfonic acid solution with a mass solid content of 5.0% of the cation exchange resin solution, wherein the solvent is ethanol, and the solute is domestic perfluorosulfonic acid resin (PFSA). Copper plates were used as the working electrode and the counter electrode respectively, and the working electrode was wrapped with the ePTFE membrane impregnated with the above solution.

[0031] Put the working electrode and the counter electrode vertically into the solution, and place them parallel to each other (the side of the working electrode wrapped with ePTFE membrane is placed parallel to the counter electrode), the vertical distance between the two is 0.5cm, and the wetting area of the working electrode in the solution is 100cm 2 . The constant voltage mode was adopted, the voltage was set to 1.0V, and the electrodeposition time was set to 400s.

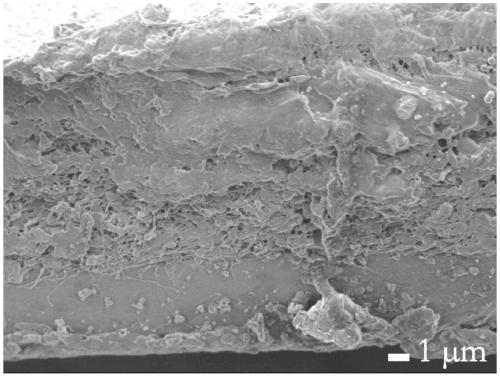

[0032] Working current density from -0.53mA / cm 2 down to -0.18mA / cm 2 , Take out the working electrod...

Embodiment 2

[0034] The mass solid content of configuration cation exchange resin solution is 5.0% perfluorosulfonic acid solution, wherein solvent is the mixed solution of ethanol and DMSO (the volume ratio of ethanol and DMSO is 6:4), and solute is domestic PFSA. Stainless steel plates were used as the working electrode and the counter electrode respectively, and the working electrode was wrapped with the ePTFE membrane impregnated with the above solution.

[0035] Put the working electrode and the counter electrode vertically into the solution, and place them parallel to each other (the side of the working electrode wrapped with ePTFE membrane is placed parallel to the counter electrode), the vertical distance between the two is 0.5cm, and the wetting area of the working electrode in the solution is 100cm 2 . The constant voltage mode was adopted, the voltage was set to 1.0V, and the electrodeposition time was set to 400s.

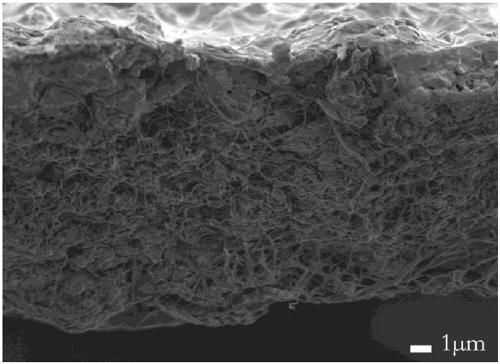

[0036] Working current density from -0.63mA / cm 2 down to -...

Embodiment 3

[0038] The mass solid content of configuration cation exchange resin solution is 5.0% perfluorosulfonic acid solution, wherein solvent is the mixed solution of ethanol and DMSO (the volume ratio of ethanol and DMSO is 6:4), and solute is domestic PFSA. Copper plates were used as the working electrode and the counter electrode respectively, and the working electrode was wrapped with the ePTFE membrane impregnated with the above solution.

[0039] Put the working electrode and the counter electrode vertically into the solution, and place them parallel to each other (the side of the working electrode wrapped with the ePTFE membrane is placed parallel to the counter electrode). The wetting area of the working electrode in the solution is 100cm 2 , and the distance to the electrode is 0.5cm. Using constant current mode, the current density is set to -0.25mA / cm 2 , The electrodeposition time is set to 400s.

[0040] The working voltage is increased from 0.27V to 0.90V, take out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com