Battery management system and method therefor

A battery management system and battery management technology, applied in the field of management systems, can solve problems such as high failure rate, high cost of battery management systems, and increased circuit area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0058] Hereinafter, the present invention will be described in detail by illustrating various embodiments of the present invention by means of drawings. Inventive concepts may however be embodied in many different forms and should not be construed as limited to the illustrative embodiments set forth herein.

[0059] The present invention breaks the conventional way that each battery in the battery module is equipped with a control circuit to detect the electrical properties of the battery, thus providing a battery management method, the user can switch the detected battery through a single control circuit through the Wheatstone bridge measured battery.

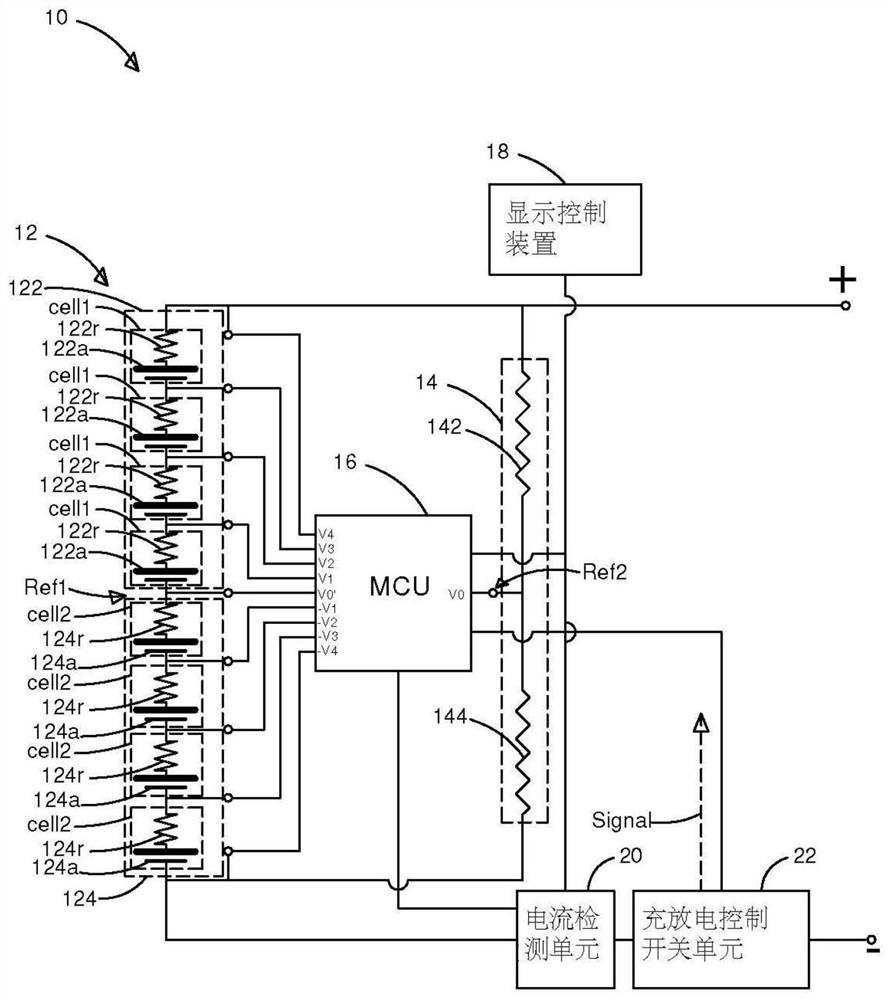

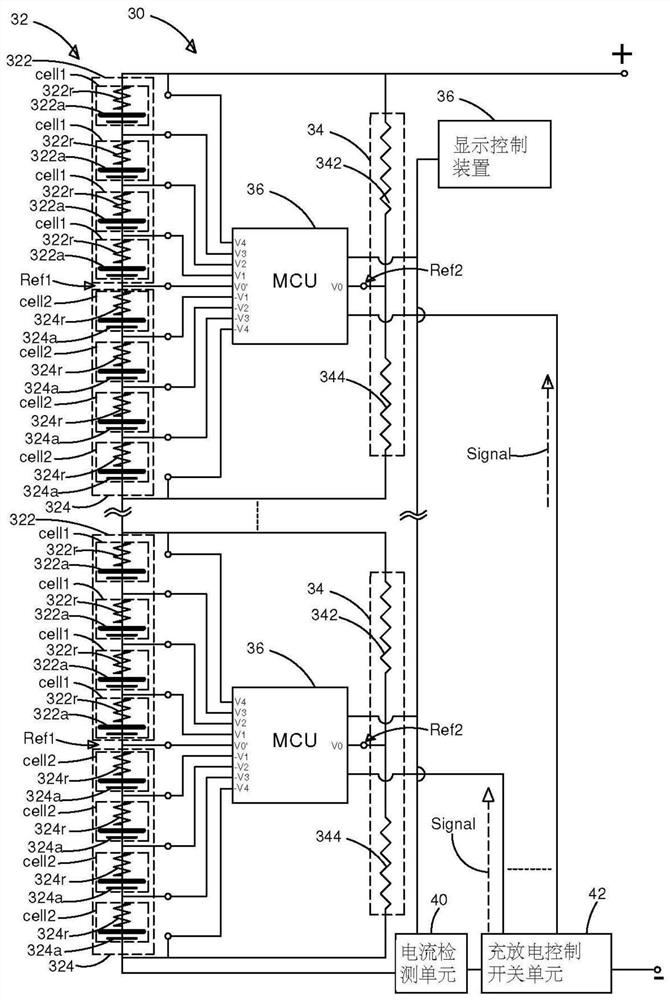

[0060] First, see figure 1 , which is a system diagram of an embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com