Energy-saving direct-current charging pile

A technology of DC charging piles and charging piles, which is applied in the field of electric power, can solve problems such as increased power consumption of charging piles, shortened service life of batteries, easy drumming, and aging, and achieves the goals of improving service life, saving energy, and achieving heat preservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

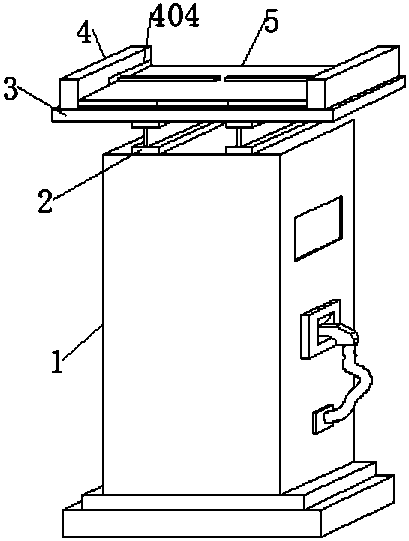

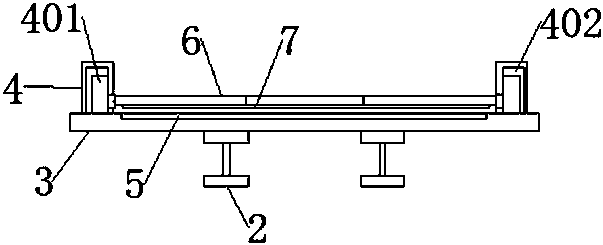

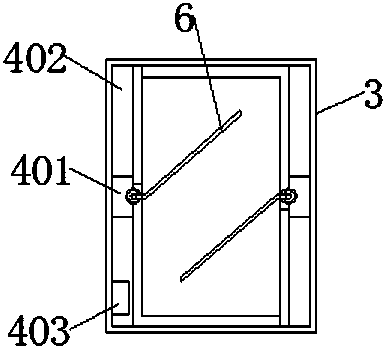

[0019] Example: see Figure 1-4 Among them, an energy-saving DC charging pile provided in this embodiment includes a charging pile 1, a bracket 2 is arranged above the charging pile 1, a support frame 3 is arranged above the bracket 2, and both sides of the support frame 3 are arranged There is a heat insulation shield 4, the upper surface of the support frame 3 is provided with a solar panel 5, and the solar panel 5 is located between the two heat insulation shields 4, and the middle end of the heat insulation shield 4 is provided with a rain A scraper motor 401, batteries 402 are provided on both sides of the heat shield 4, a PLC controller 403 is provided inside the support frame 3, a wiper arm 6 is provided at one end of the wiper motor 401, and a wiper arm 6 is provided at one end of the wiper motor 401. The motor 401 is connected to the PLC controller 403 by signals, and the wiper motor 401 and the PLC controller 403 are both connected to the battery 402 through wires. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com