Cool-feeling yarn three-layer summer quilt and manufacturing method thereof

A production method and cooling technology, applied in textile, application, fabric and other directions, can solve the problems of high cost, cumbersome processing, accidental human injury, etc., and achieve the effect of reducing accidental injury, reducing production cost, and increasing thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

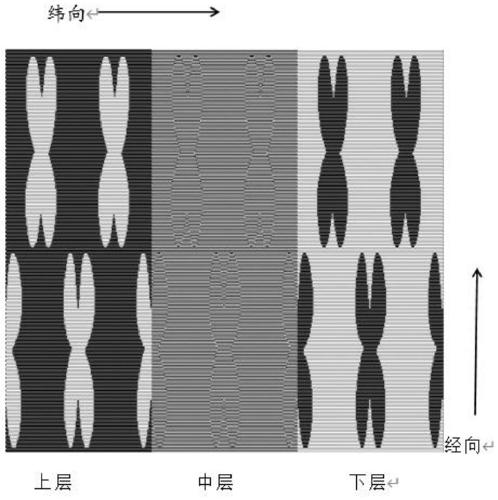

Image

Examples

Embodiment 1

[0029] Example 1 Make a three-layer summer cool quilt of cool-feeling yarn

[0030] Material:

[0031] 150D / 75F polyester and nylon mixed cool yarn, 32S / 2 hollow cotton yarn.

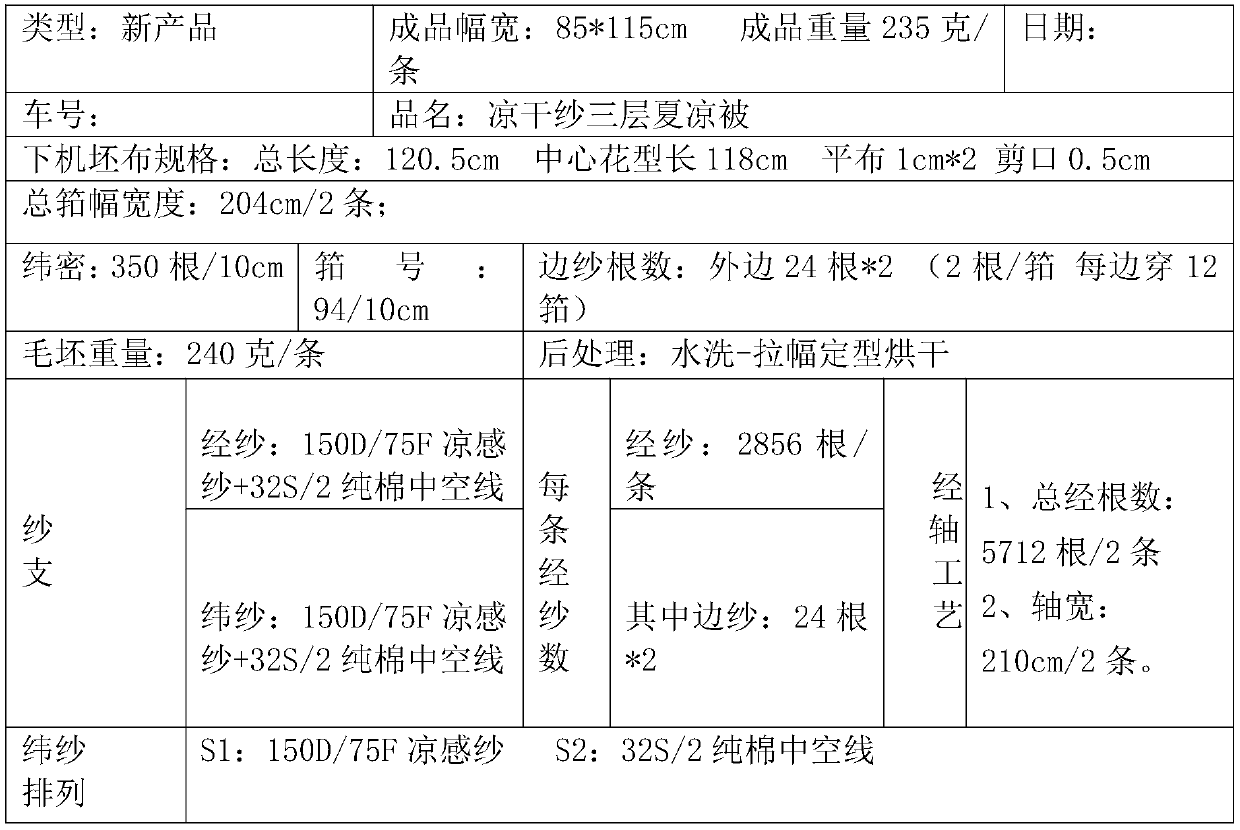

[0032] The process parameters are shown in Table 1.

[0033] Table 1

[0034]

[0035] Production Method:

[0036] (1) Raw yarn dyeing: process the cool-feeling yarn on the upper and lower surfaces into colored yarns of two colors, and process the hollow yarn in the middle layer into original white yarn without fluorescence;

[0037] (2) Warping: the upper and lower layers of total cooling yarns and hollow yarns are arranged in a ratio of 2:1, and the density of the fixed-width reeds is 27.2 pieces / cm, and the warp beams are produced by the method of section warping;

[0038] (3) On the machine: According to the warp yarn density of 94 reeds / 10cm, each heddle is threaded with 1 warp yarn, and each reed tooth is threaded with 3 warp yarns, and the weft yarn is 1 upper layer cool yarn, 1 middle lay...

Embodiment 2

[0042] Embodiment 2 softness detection

[0043] Get the cool-feeling yarn three-layer summer cool quilt of embodiment 1 and common pure cotton summer cool quilt, be folded into the height under natural state and be respectively 5.5cm, then respectively increase the external force compression of 1kg above, the cool-feel yarn three-layer summer cool quilt The compressed coolness is 2.3cm, and the ordinary pure cotton summer cool is 3.5cm after compression, so the softness of the three-layer summer cool quilt with cool feeling yarn can be increased by about 34% compared with ordinary fabrics.

Embodiment 3

[0044] Embodiment 3 cool feeling test

[0045] Put water at 50°C into two glasses with the same volume of water in the glasses, and then completely cover the two glasses of water with the three-layer summer cool quilt of cooling yarn in Example 1 and the ordinary pure cotton summer cool quilt Hold for 15 minutes and then measure the temperature of the water in the water glass. The test results show that the temperature of the water in the cup covered with the three layers of cool-feeling yarn in Example 1 drops by 20°C, and the temperature of the water in the cup covered by ordinary Xialiang drops by 13°C. From the experiment, it can be seen that It is found that compared with the ordinary summer cool quilt, the three-layer cool summer quilt with cool feeling yarn has a 30% higher temperature drop rate in the same time, so people feel cool when covered with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com