Preparation method of stable super-hydrophobic antibacterial cotton woven fabric based on glutaraldehyde cross-linking

A technology of glutaraldehyde cross-linking and cotton fabrics, which is applied in the direction of plant fibers, textiles and papermaking, and liquid-repellent fibers, can solve the problems of weakening superhydrophobicity, losing antibacterial properties, and containing toxicity, and achieves the preparation method Simple, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

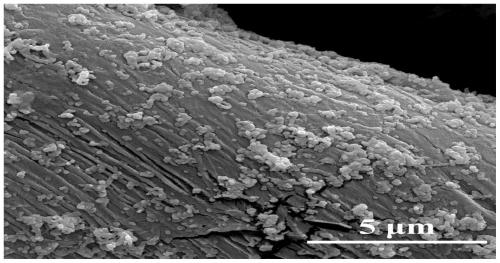

Image

Examples

Embodiment 1

[0026] (1) Wash the cotton fabric with deionized water and absolute ethanol in turn, and then dry it at 60°C;

[0027] (2) Add 1.0mol silver nitrate and 4.0mol tannic acid into water to obtain a mixed solution, adjust the pH value of the mixed solution to 7.1, then ultrasonically treat it for 10 minutes, and soak the dried cotton fabric in the mixed solution in step (1) , at 30°C, with a stirring speed of 80r / min, stirring and reacting for 4 hours, taking out the reacted cotton fabric, washing it with deionized water and absolute ethanol in turn, and drying at 80°C for 3 hours;

[0028] (3) Dissolve glutaraldehyde in ethanol and dilute to obtain a solution B with a glutaraldehyde concentration of 1 wt%, soak the dried cotton fabric in step (2) in solution B, react at 25°C for 18 hours, take out After the reaction, the cotton fabric was washed with deionized water and absolute ethanol successively, and dried at 75° C. for 4 hours;

[0029] (4) Put the cotton fabric dried in st...

Embodiment 2

[0031] (1) Wash the cotton fabric with deionized water and absolute ethanol successively, and then dry it at 80°C;

[0032] (2) Add 1.0mol silver nitrate and 3.2mol tannic acid into methanol to obtain a mixed solution, adjust the pH value of the mixed solution to 8.0, then ultrasonically treat it for 5 minutes, and soak the dried cotton fabric in the mixed solution in step (1) , at 25°C, with a stirring speed of 100r / min, stirring and reacting for 6 hours, taking out the reacted cotton fabric, washing it with deionized water and absolute ethanol in turn, and drying at 85°C for 5 hours;

[0033] (3) Dissolving glutaraldehyde in water and diluting to obtain a solution B with a glutaraldehyde concentration of 3wt%, soaking the dried cotton fabric in step (2) in solution B, reacting at 40°C for 12 hours, and taking out the reaction After the cotton fabric is washed with deionized water and absolute ethanol successively, and dried at 80° C. for 3 hours;

[0034] (4) Put the cotton...

Embodiment 3

[0036] (1) Wash the cotton fabric with deionized water and absolute ethanol in turn, and then dry it at 70°C;

[0037] (2) Add 1.0mol silver nitrate and 4.8mol tannic acid into ethanol to obtain a mixed solution, adjust the pH value of the mixed solution to 8.8, then ultrasonically treat it for 15 minutes, and soak the dried cotton fabric in the mixed solution in step (1) , at 40°C, with a stirring speed of 120r / min, stirring and reacting for 2 hours, taking out the reacted cotton fabric, washing it with deionized water and absolute ethanol in turn, and drying at 75°C for 2 hours;

[0038] (3) Dissolve glutaraldehyde in methanol and dilute to obtain a solution B with a glutaraldehyde concentration of 5 wt%, soak the dried cotton fabric in step (2) in solution B, react at 35°C for 24 hours, and take out After the reaction, the cotton fabric was washed with deionized water and absolute ethanol successively, and dried at 85° C. for 2 hours;

[0039] (4) Put the dried cotton fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com