Thermal insulation wall material and manufacturing process thereof

A technology of thermal insulation wall and production process, applied in the field of building materials, can solve the problems of not taking into account physical properties, thermal insulation properties and fire resistance properties, etc., and achieve the effects of high compressive strength, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

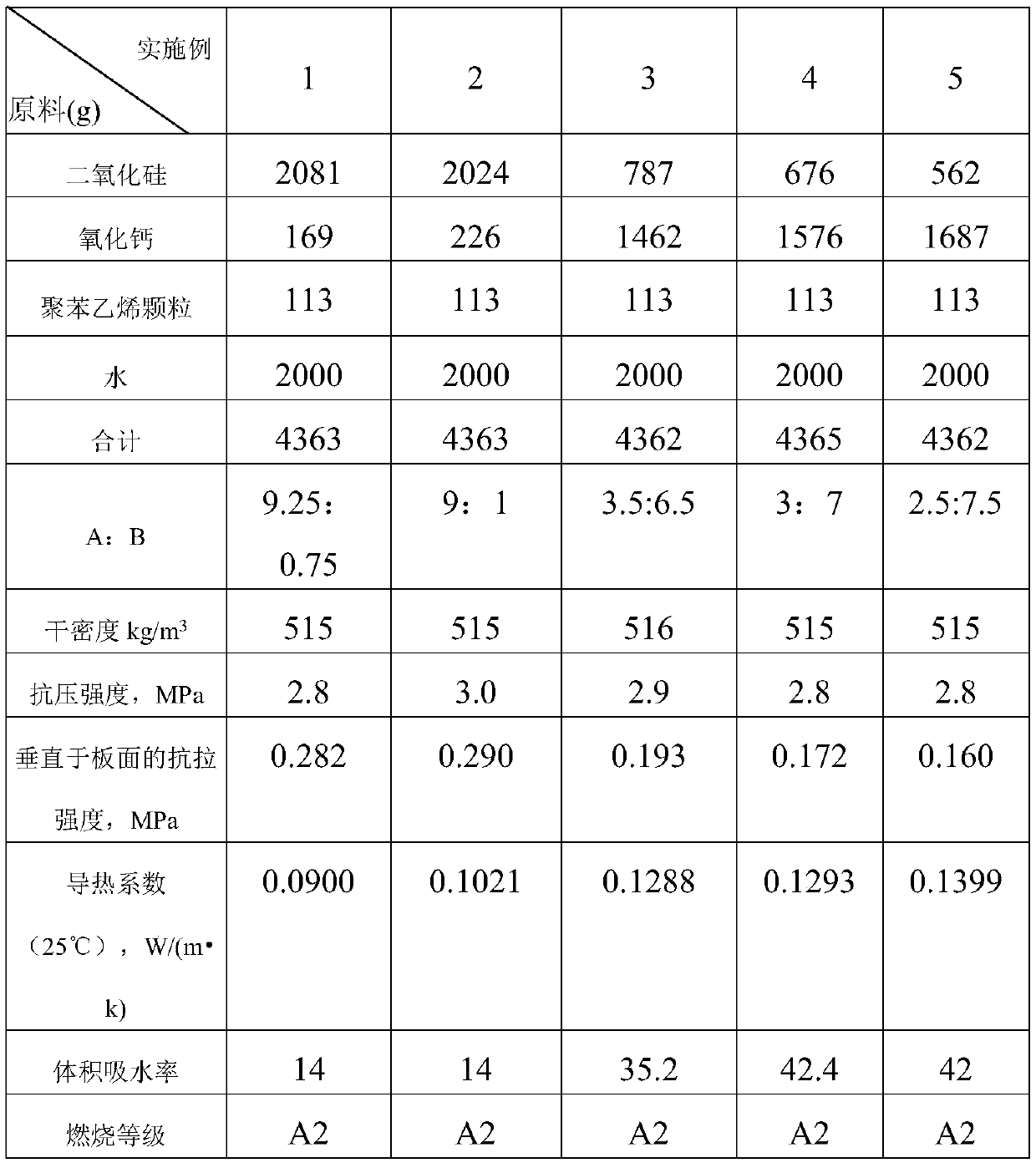

Examples

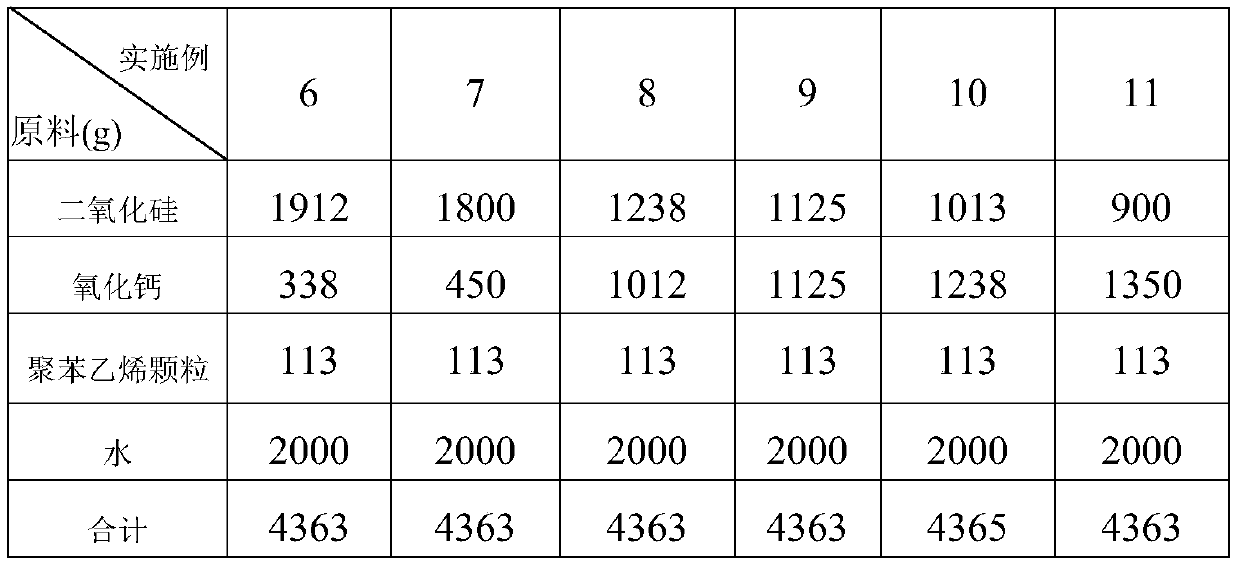

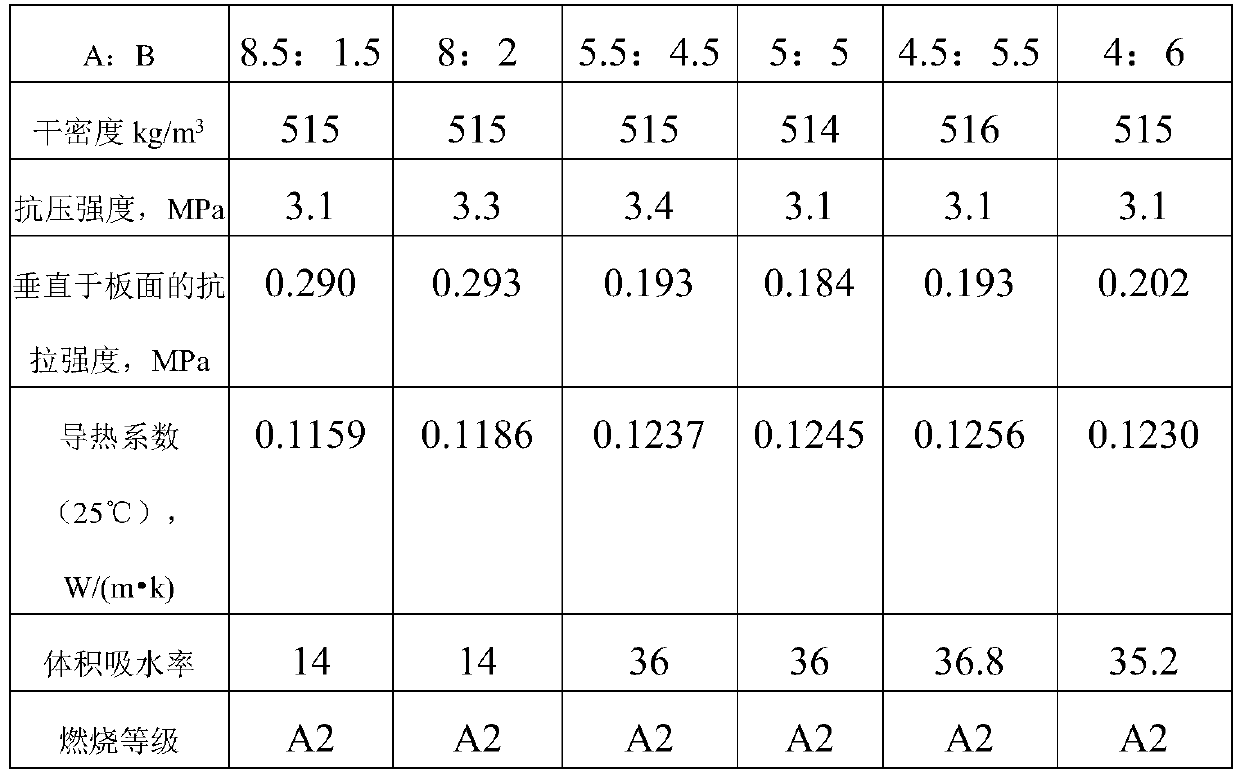

Embodiment 22-27

[0055]

[0056]

[0057] Table 6 relates to the embodiment 28-32 of different inorganic-organic ratios

[0058]

[0059] Table 7 relates to Examples 33-38 of adding water reducers under different silicon-calcium ratios

[0060]

[0061]

[0062] Table 8 relates to the examples 39-44 of adding water reducing agents under different silicon-calcium ratios

[0063]

[0064]

[0065] Table 9 relates to Examples 45-52 of adding water reducers under different inorganic-organic ratios

[0066]

Embodiment 53-60

[0068]

[0069] Table 11 relates to Examples 61-67 of different water reducing agent addition ratios

[0070]

[0071]

Embodiment 68-75

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com