A kind of slag system for iron-based amorphous alloy strip and a preparation method of iron-based amorphous alloy strip

An iron-based amorphous alloy and slag-based technology, which is applied in the field of iron-based amorphous alloys, can solve the problems of difficulty in magnetic core preparation, the influence of the straightness of the spray belt, and the inability to completely discharge the inclusions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present application also provides a method for preparing an iron-based amorphous alloy strip, comprising the following steps:

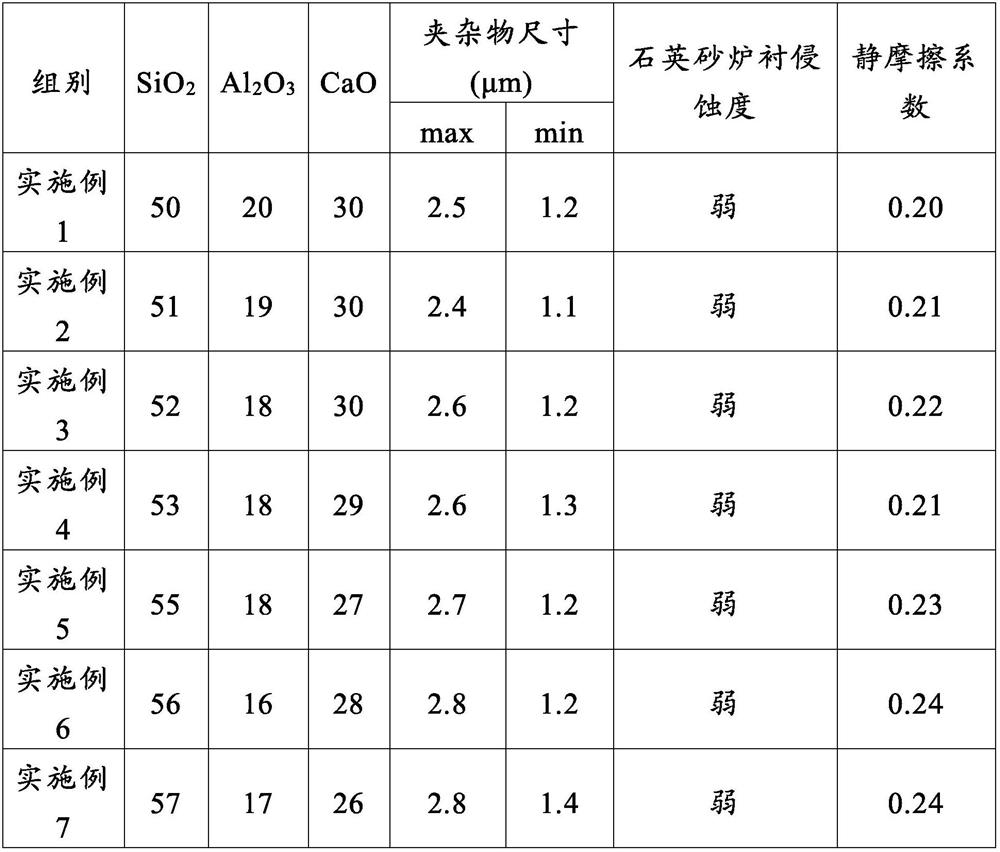

[0027] Raw materials are prepared according to the composition ratio of iron-based amorphous alloy strips, and the raw materials and slag are smelted in an intermediate frequency furnace lined with quartz sand to obtain molten steel; the slag is made of 50-60 wt% SiO 2 , 15-20wt% Al 2 o 3 And 25 ~ 30wt% CaO composition;

[0028] The molten steel is rapidly quenched by a single roll to obtain an iron-based amorphous alloy strip.

[0029] The preparation method of the iron-based amorphous alloy strip described in the present application is carried out according to methods well known to those skilled in the art, except that a slag system with a specific composition is used for slagging during the smelting process, so as to realize the removal of inclusions in molten steel; wherein The silicon dioxide and calcium oxide are additional slag co...

Embodiment

[0033] Raw materials are prepared according to the composition of iron-based amorphous alloy strips, and the total amount of alumina brought into the raw materials is 0.6kg (calculation of the amount of alumina: 1000kg of aluminum-containing raw materials, wherein the aluminum content is 0.03%, then the amount of aluminum brought in is 0.3kg, the total amount of alumina calculated from the alumina-oxygen reaction is 0.6kg) The slag system is based on SiO 2 50~60wt%, Al 2 o 3 15-20wt%, CaO 25-30wt% ratio, the calculated amount of glass to be added is about 2kg, and the amount of calcium oxide is about 1kg;

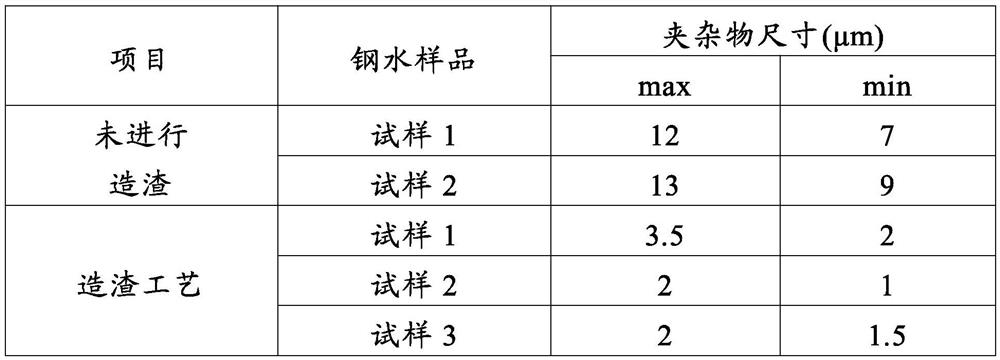

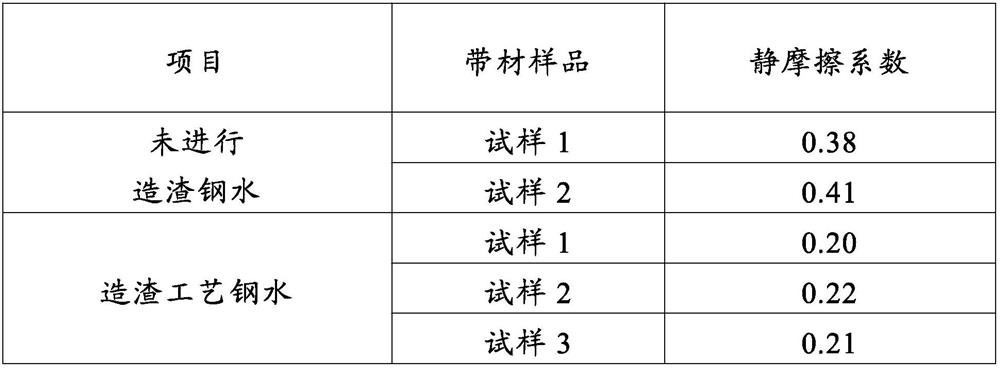

[0034] When smelting raw materials, the prepared glass and calcium oxide are fully mixed and then put into the furnace for melting. During the smelting process, the slag is not allowed to be taken out, and the molten steel is taken out before the molten steel is tapped. The Fe- Si-B series molten steel, non-metallic inclusions in molten steel are shown in Table 1;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com