A construction wall slurry throwing device

A technology of slurry throwing and construction, which is applied in construction and building structure, etc., can solve the problems of low slurry throwing efficiency and large labor load of external walls, and achieve the effects of high speed, material saving and uniform spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

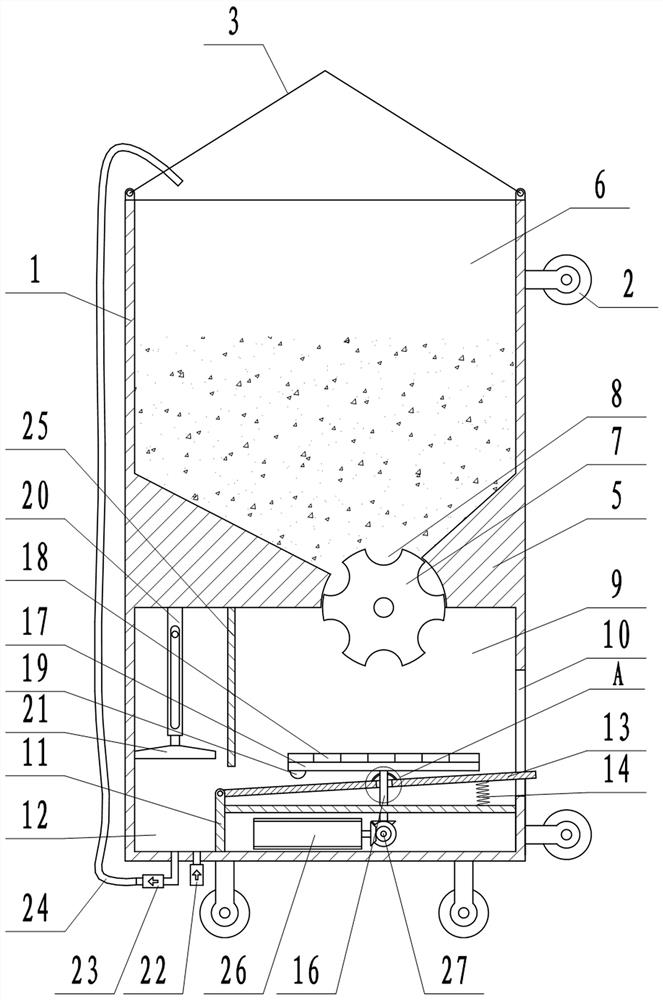

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

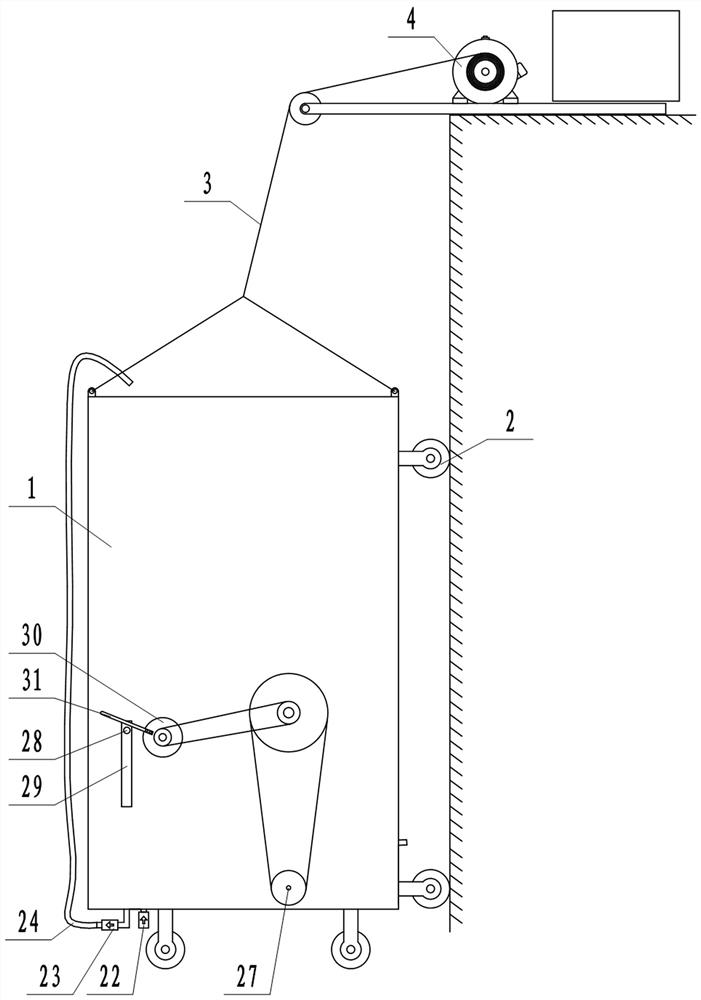

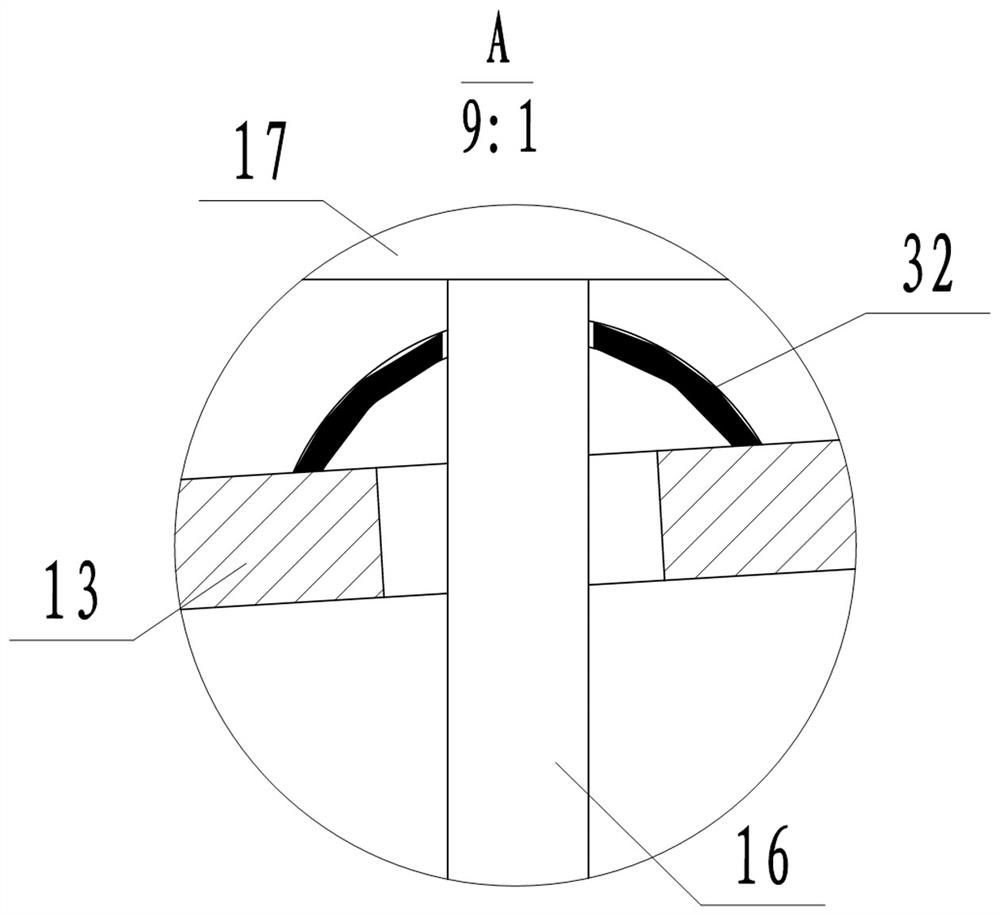

[0016] Depend on Figure 1 to Figure 5 Given, the present invention comprises box body 1, and the right side of box body 1 and the bottom all are equipped with a plurality of rollers 2, and the upper end of box body 1 is tied with rope 3, and rope 3 is wound on the winch 4; There is a partition 5, the top of the partition 5 is a material storage area 6, and a rotatable distribution tray 7 is installed on the partition 5, and a plurality of grooves 8 are evenly distributed on the circumference of the outer edge of the distribution tray 7; A vertical vertical plate 11 is installed on the base plate of the body 1, the left side of the vertical plate 11 is a return area 12, the right side is a material rejection area 9, and the right side of the material rejection area 9 has an opening 10;

[0017] The vertical plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com