A kind of method and device for one-step preparation of red vitriol sodium with chromite as raw material

A technology of chromite and red vanadium sodium, applied in the direction of chromate/dichromate, etc., can solve problems such as low production efficiency, health threats, secondary pollution, etc., and achieve reduction of energy waste, reduction of environmental pollution, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

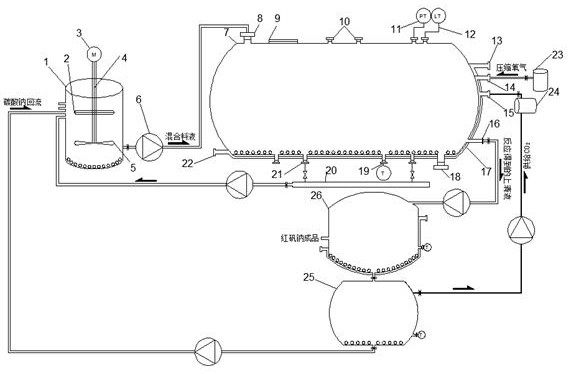

[0030] A kind of device that takes chromite as raw material to prepare red vitriol sodium in one step, such as figure 1 As shown, it includes mixing device 1, stirring device, horizontal reactor 7, waste liquid tank 20, oxygen tank 23, carbon dioxide gas tank 24, decomposition tank 25, separation tank 26, pumps and valves, and mixing device 1 is also equipped with There are heating resistors and thermometers, which are used for heating and temperature measurement respectively. The mixing device 1 is equipped with a stirring device, which includes a self-priming paddle 2, a motor 3, a stirring rod 4, an open worm gear stirring blade 5, and a stirring rod 4 One end passes through the top of the mixing device 1 and is connected to the motor 3. The middle part of the stirring rod 4 is provided with a self-priming paddle 2, and the bottom of the stirring rod 4 is provided with an open-type worm gear stirring blade 5. The self-priming paddle 2 stirs the feed liquid upwards. The open...

Embodiment 2

[0042] Adopting the device of embodiment 1, the upper emptying port and the lower emptying port are one, and using chromite as raw material to prepare red vitriol sodium in one step, the concrete method steps are as follows:

[0043] (1) Add chromite containing elemental Cr with a mass percentage content of 68%, soda ash with a purity of 99%, sodium hydroxide with a purity greater than 96%, and water to the mixture according to the mass ratio of 1:1.05:0.45:5 In device 1, turn on the motor 3 and the heating resistor, stir and mix evenly while heating, stop heating and stirring after the temperature measured by the thermometer reaches 100°C, and obtain the mixed liquid material;

[0044] (2) The mixed liquid material in step (1) is drawn out from the feed liquid outlet of the mixing device 1 by the booster pump 6 and enters the horizontal reactor 7 from the mixed material liquid port 8, and the horizontal reactor is obtained from the liquid level gauge 12 After the liquid level...

Embodiment 3

[0051] Adopt the device of embodiment 1, the upper emptying port and the lower emptying port are two, take chromite ore as raw material and prepare red vitriol sodium in one step, and the concrete method steps are as follows:

[0052] (1) Add chromite containing elemental Cr with a mass percentage content of 68%, soda ash with a purity of 99%, sodium hydroxide with a purity greater than 96%, and water to the mixture according to the mass ratio of 1:1.1:0.5:5 In device 1, turn on the motor 3 and the heating resistor, stir and mix evenly while heating, stop heating and stirring after the temperature measured by the thermometer reaches 100°C, and obtain the mixed liquid material;

[0053] (2) The mixed liquid material in step (1) is drawn out from the feed liquid outlet of the mixing device 1 by the booster pump 6 and enters the horizontal reactor 7 from the mixed material liquid port 8, and the horizontal reactor is obtained from the liquid level gauge 12 After the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com