Unloading system for three-dimensional high-temperature continuous heat treatment production system

A technology of production system and heat treatment furnace, applied in the field of unloading device, can solve the problems of slow cooling speed, short furnace life, affecting product quality, etc., and achieve the effect of rapid recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

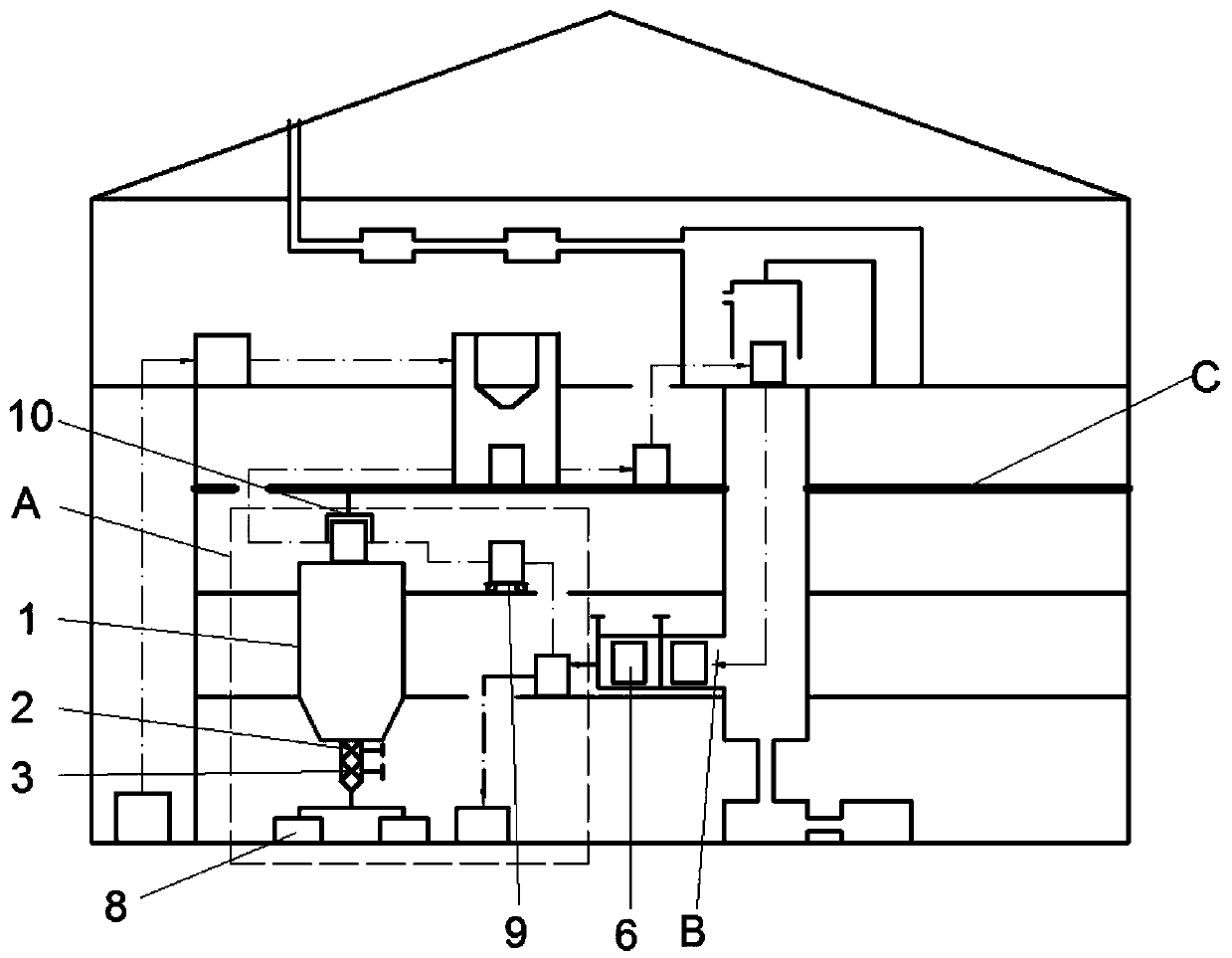

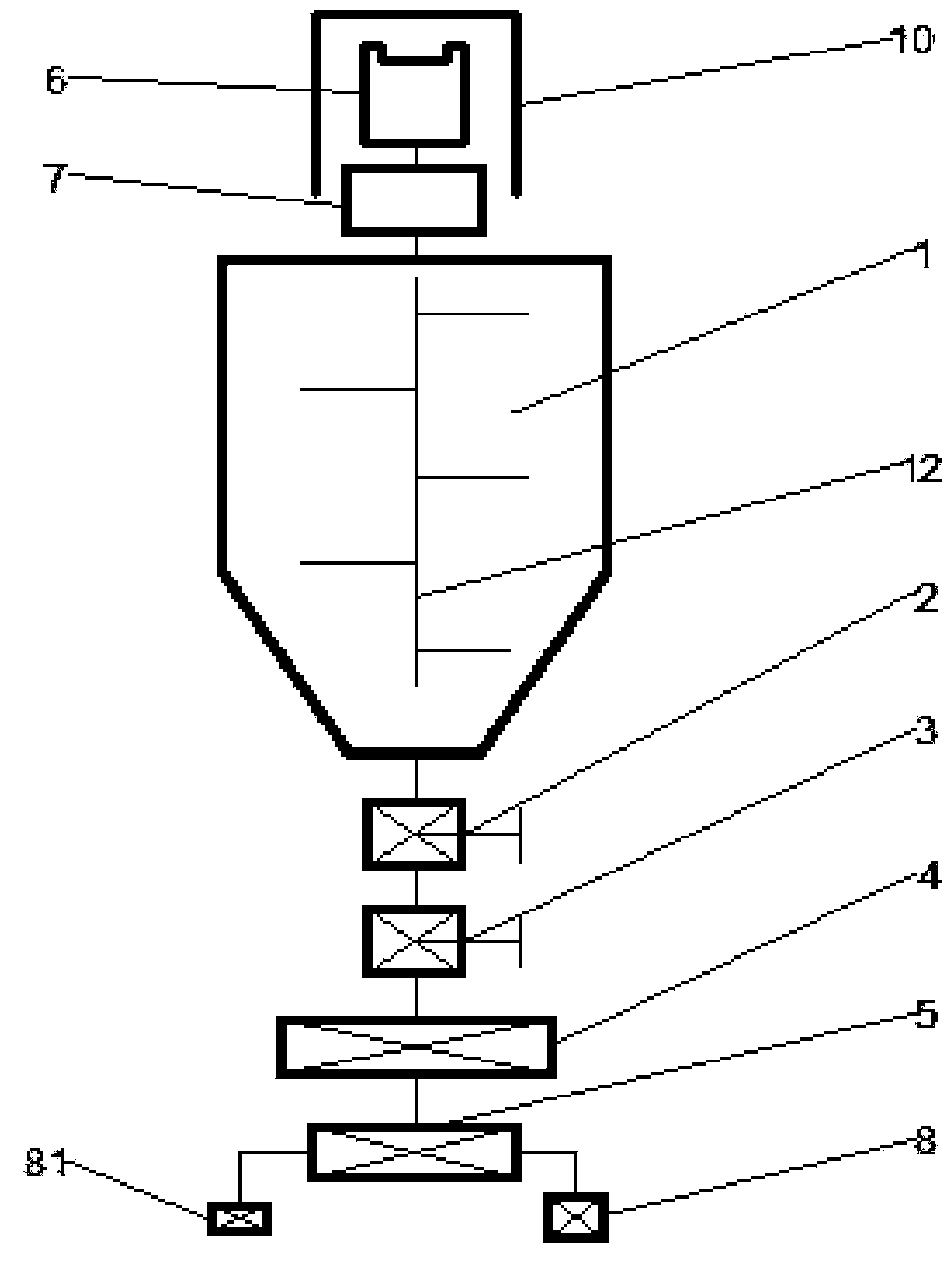

[0030] As shown in the figure, a three-dimensional high-temperature continuous production system is provided. The production system is set in a multi-storey production workshop, including a loading module, a heat treatment module, an unloading module, and an electrical control module (not shown).

[0031] According to the structural size of each module in the production system, the multi-storey production workshop in this embodiment is set to 5 floors, and the workshop is divided into high-rise and low-rise, and the high-rise and low-rise are separated by floor slabs. figure 1 Middle C is the separation interface, the upper layer is used for loading, and the lower layer is used for discharging. The upper layer is for raw materials, and the lower layer is for heat-treated products. The materials in the upper and lower layers are not allowed to be mixed. The lower floors are divided into layer 1, layer 2, and layer 3 from low to high, and the upper floors are divided into layer 4...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the unloading bin of this embodiment is installed on the first and second floors, the discharge port is placed on the first floor, and the material inlet is placed on the second floor, and the vertical continuous high-temperature heat treatment on the second floor After preliminary quality inspection, the loading boats taken out of the furnace discharge bin can be directly sent to the inlet of the unloading bin by the AGV trolley 9. The volume of the unloading bin in this arrangement is small, which is suitable for rapid processing in the case of small-volume processing. unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com