Wearable flexible pressure electronic sensor and manufacturing method

An electronic sensor and pressure sensor technology, applied in the field of sensors, can solve the problems of limited deformation degree, general sensitivity, and limited application in the field of wearable body sign detection, and achieve the effect of improving deformation force, sensitivity and large deformation force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

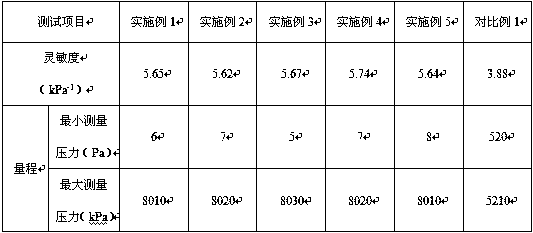

Examples

Embodiment 1

[0029] The wearable flexible pressure electronic sensor consists of a flexible curved polyimide film layer, an electrode layer, a dielectric layer, an electrode layer and a flexible curved polyimide film layer from bottom to top. The curvature of the flexible curved polyimide film layer is 4000R, and the thickness is 20 μm. The curved surfaces of the two flexible curved polyimide film layers are combined relative to the concave and convex. The material of the electrode layer is a mixed electrode of graphite and pure copper, with a thickness of 10 μm. The material of the dielectric layer is a polyvinylidene fluoride film with a thickness of 50 μm.

[0030] Made by the following steps:

[0031] a. Spin-coating polyimide on a flexible silica gel substrate with a curved surface to obtain a flexible curved polyimide film layer;

[0032] b. The flexible curved polyimide film layer, the electrode layer, the dielectric layer, the electrode layer, and the flexible curved polyimide f...

Embodiment 2

[0036] The wearable flexible pressure electronic sensor consists of a flexible curved polyimide film layer, an electrode layer, a dielectric layer, an electrode layer and a flexible curved polyimide film layer from bottom to top. The curvature of the flexible curved polyimide film layer is 2500R, and the thickness is 30 μm. The curved surfaces of the two flexible curved polyimide film layers are combined relative to the concave and convex. The material of the electrode layer is a mixed electrode of graphite and pure copper, with a thickness of 10 μm. The material of the dielectric layer is polystyrene film with a thickness of 50 μm.

[0037] Made by the following steps:

[0038] a. Spin-coating polyimide on a flexible silica gel substrate with a curved surface to obtain a flexible curved polyimide film layer;

[0039] b. The flexible curved polyimide film layer, the electrode layer, the dielectric layer, the electrode layer, and the flexible curved polyimide film layer are ...

Embodiment 3

[0043] The wearable flexible pressure electronic sensor consists of a flexible curved polyimide film layer, an electrode layer, a dielectric layer, an electrode layer and a flexible curved polyimide film layer from bottom to top. The curvature of the flexible curved polyimide film layer is 3000R, and the thickness is 28 μm. The curved surfaces of the two flexible curved polyimide film layers are combined relative to the concave and convex. The material of the electrode layer is a mixed electrode of graphite and pure copper, with a thickness of 5 μm. The material of the dielectric layer is polycarbonate film with a thickness of 70 μm.

[0044] Made by the following steps:

[0045] a. Spin-coating polyimide on a flexible silica gel substrate with a curved surface to obtain a flexible curved polyimide film layer;

[0046] b. The flexible curved polyimide film layer, the electrode layer, the dielectric layer, the electrode layer, and the flexible curved polyimide film layer are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com