Multi-position synchronous thermal shrinkage wiring harness thermal shrinkage equipment, integrated device and method

A multi-position, heat-shrinking technology, which is applied in the assembly/disassembly of contacts, vehicle connectors, connection insulation, etc., can solve the problems of large position changes of the second heat-shrinkable tube b and differences in heat-shrinking process, and achieve adaptability Strong performance, efficient heat shrinkage, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

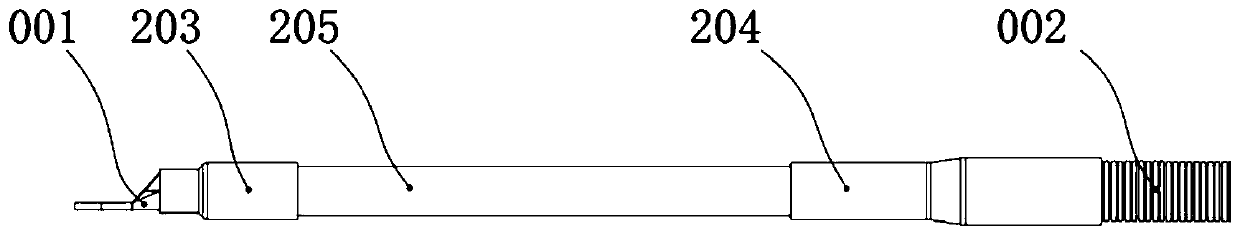

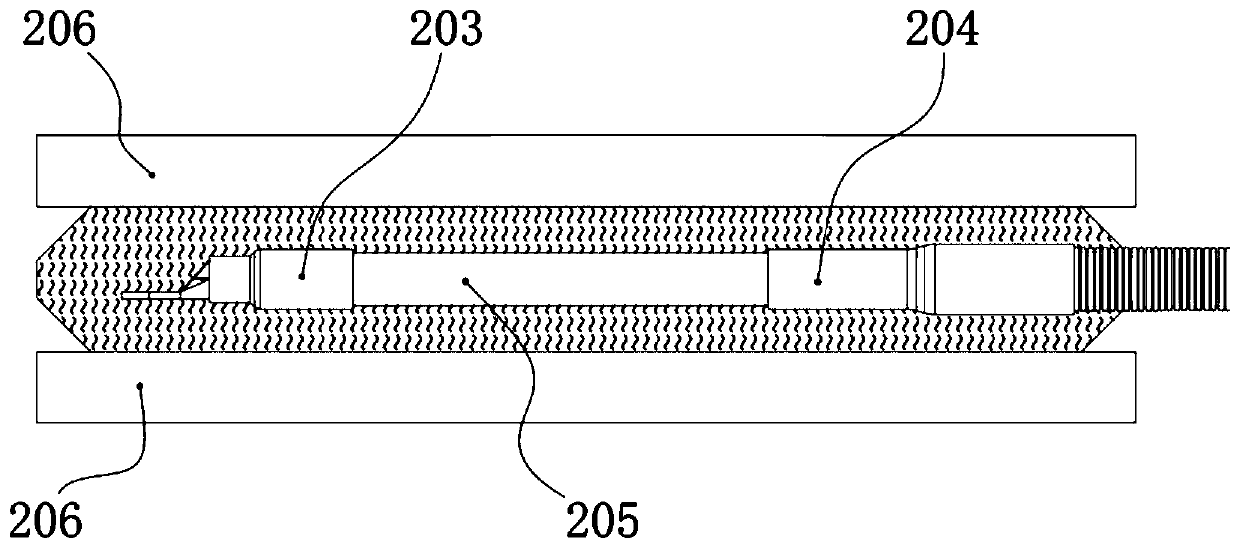

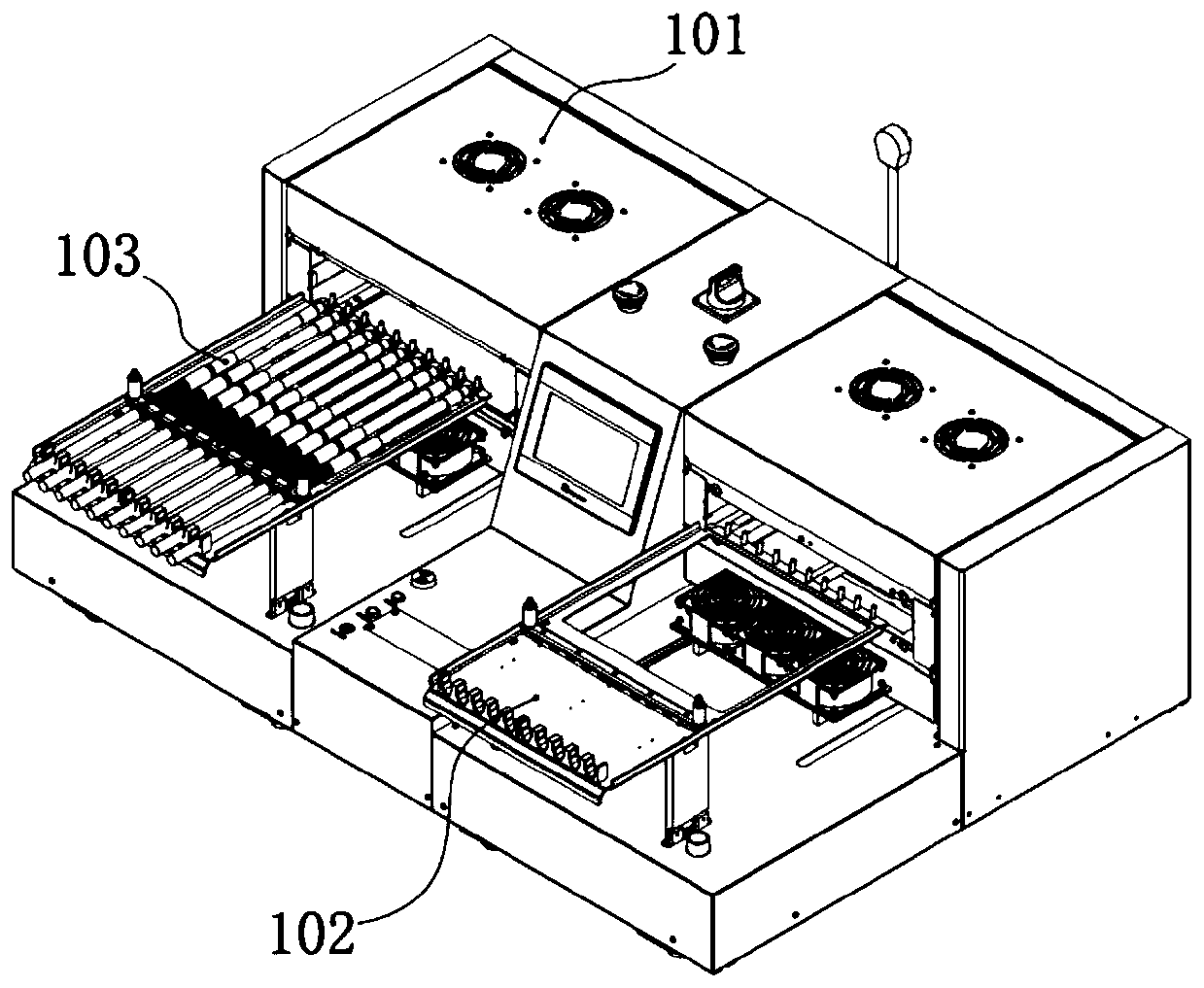

[0048] Such as figure 1 As shown in the figure, for the sake of easy understanding, a structural form of the heat-shrinkable wire harness is shown, which is a common form in new energy vehicles. In the wire harness, one end is a metal terminal 001, which is combined with one end of the wire harness body, and the other end of the wire harness body is connected and fixed with a corrugated tube 002. Therefore, in this kind of wire harness, two heat-shrinkable tubes generally need to be installed along the wire harness: one heat-shrinkable tube a203 is used for the protection of the joint between the wire harness body and the metal terminal 001, and the other heat-shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com