Load-reducing suspension system and backpack

A suspension system and component technology, applied in the field of backpacks, can solve the problems of short service life, inability to reduce the load, difficult to adjust, etc., and achieve the effects of stable and reliable sliding space, lightening the burden on the body, and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

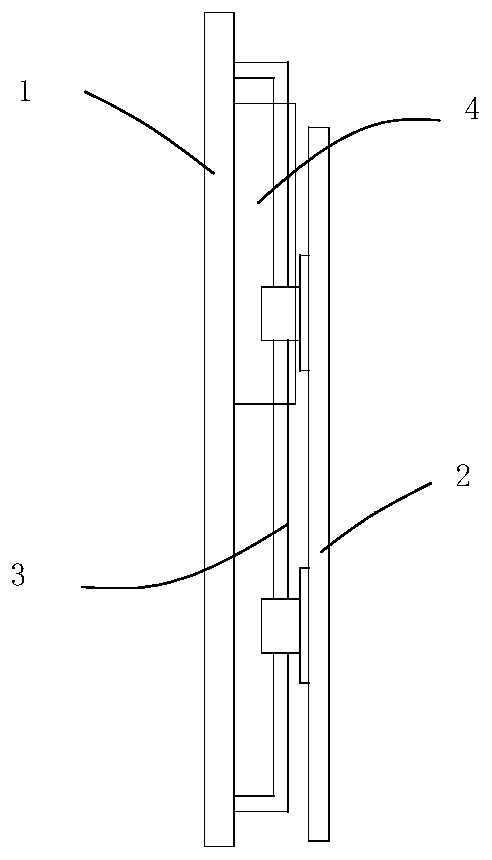

[0039] Such as Figure 1 to Figure 3 As shown, the load-reducing suspension system includes a fixed plate 1 and a sliding plate 2. The sliding plate 2 is connected to the fixed plate 1 through a sliding part 3. It is characterized in that: the fixed plate 1 is provided with an adjustable elastic component 4, which can The movable end of the adjustable elastic component 4 is connected with the sliding plate 2, and the adjustable elastic component can be adjusted according to the load on the sliding plate, so that the force output by the adjustable elastic component just offsets the gravity of the load. When it is on the board, the movable plate will move downward under the action of the load. If the sliding plate slides to the lower limit position of the sliding part, the entire load-reducing suspension system will be in a state of failure and cannot achieve the effect of reducing the load. At this time, this implementation For example, the adjustable elastic component can be a...

Embodiment 2

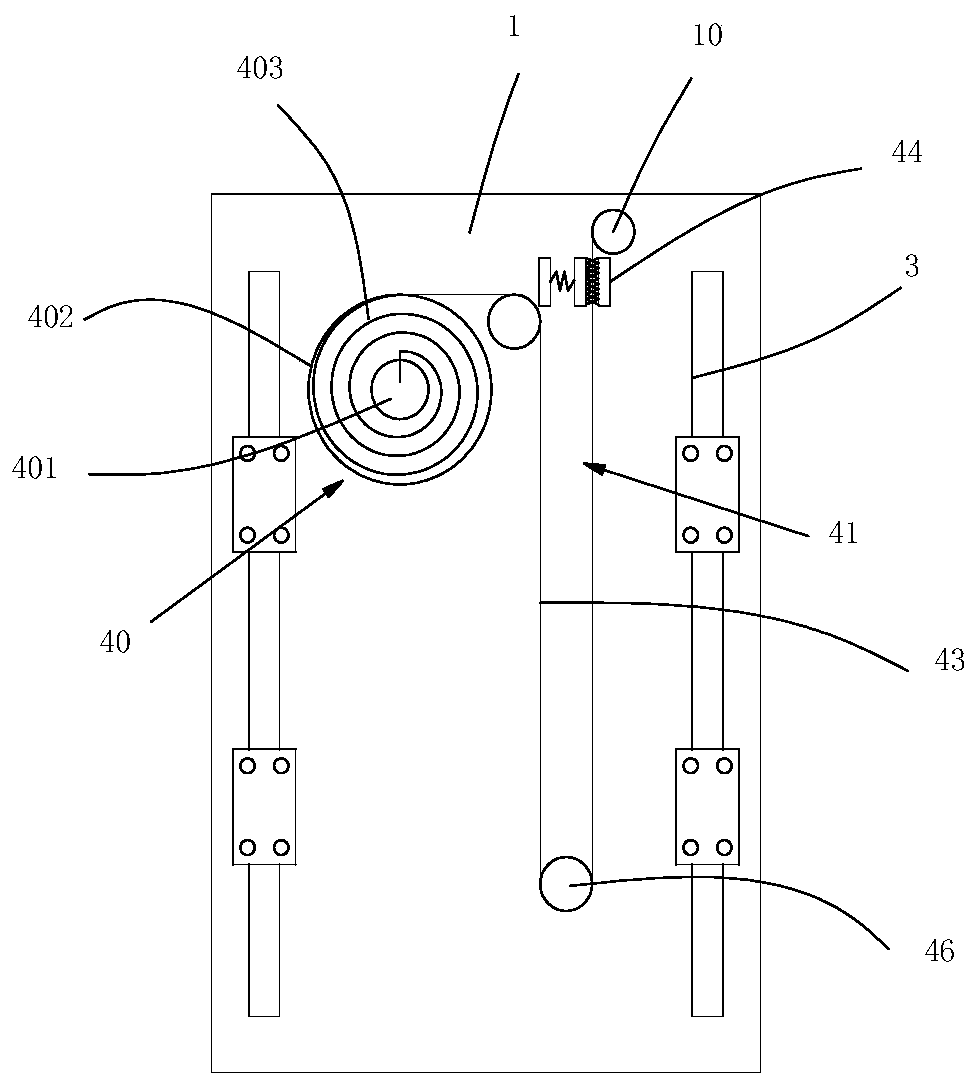

[0044] Such as figure 1 as well as Figure 4 to Figure 6 As shown, the load-reducing suspension system includes a fixed plate 1 and a sliding plate 2. The sliding plate 2 is connected to the fixed plate 1 through a sliding part 3. It is characterized in that: the fixed plate 1 is provided with an adjustable elastic component 4, which can The movable end of the adjustable elastic component 4 is connected with the sliding plate 2, and the adjustable elastic component can be adjusted according to the load on the sliding plate, so that the force output by the adjustable elastic component just offsets the gravity of the load. When it is on the board, the movable plate will move downward under the action of the load. If the sliding plate slides to the lower limit position of the sliding part, the entire load-reducing suspension system will be in a state of failure and cannot achieve the effect of reducing the load. At this time, this implementation For example, the adjustable elast...

Embodiment 3

[0050] Such as figure 1 as well as Figure 7 As shown, the load-reducing suspension system includes a fixed plate 1 and a sliding plate 2. The sliding plate 2 is connected to the fixed plate 1 through a sliding part 3. It is characterized in that: the fixed plate 1 is provided with an adjustable elastic component 4, which can The movable end of the adjustable elastic component 4 is connected with the sliding plate 2, and the adjustable elastic component can be adjusted according to the load on the sliding plate, so that the output force of the adjustable elastic component just offsets the gravity of the load.

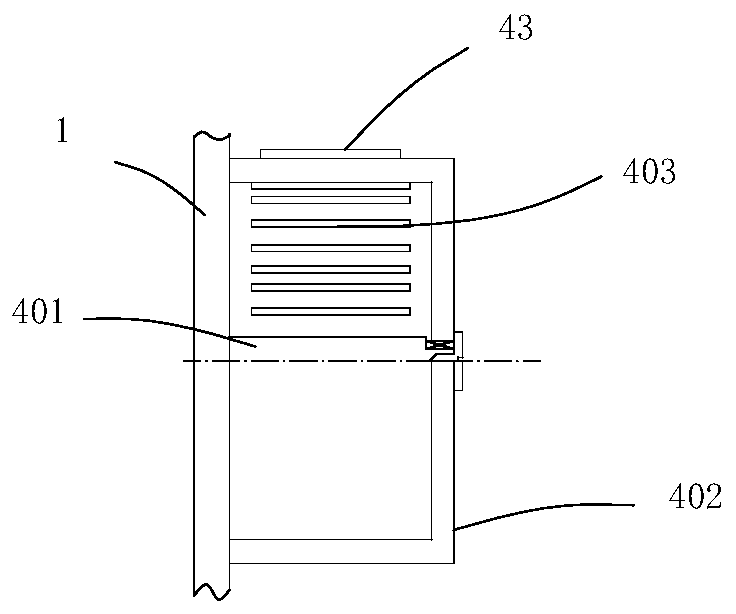

[0051] further as Figure 7 As shown, the adjustable elastic assembly 4 includes two symmetrically arranged adjustable torque assemblies 45, and the adjustable torque assembly 45 includes an adjustable mandrel assembly 450 that is installed on a fixed plate to rotate and lock. A rotatable spring box 402 is connected to the mandrel assembly, and a scroll spring 403 wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com