Pipeline scale removal device

A pipeline and heat exchange device technology, applied in the field of pipeline descaling devices, can solve the problems of difficult removal of magnesium ammonium phosphate crystals and high cost, and achieve the effect of low cost and high efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

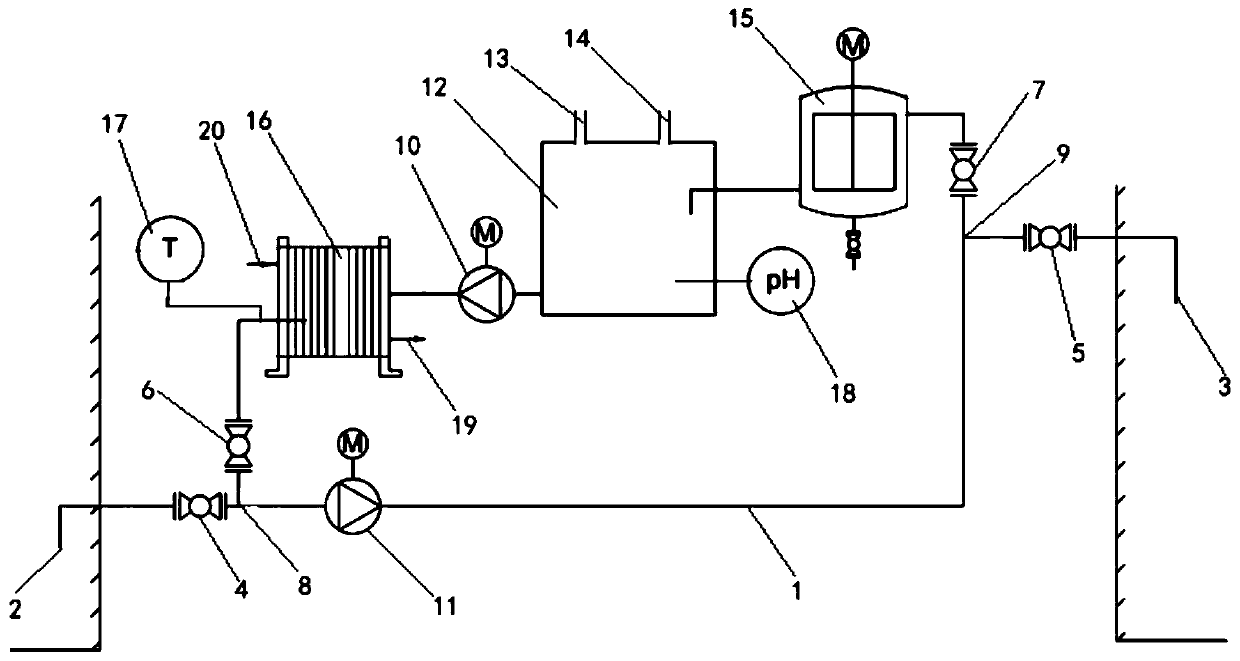

[0026] The embodiment of the present invention provides a pipeline descaling device, please refer to the attached figure 1 , for removing the crystallization of magnesium ammonium phosphate on the first pipeline 1, the first pipeline 1 includes a first inlet 2, a first outlet 3, a first hand valve 4 is arranged at the first inlet 2, a second hand A valve 5 is provided at said first outlet 3 .

[0027] Specifically, the pipeline descaling device is used to remove magnesium ammonium phosphate crystals in the first pipeline 1, the first pipeline 1 is a sewage treatment pipeline, and organic waste water enters the pipeline from the first inlet 2. In the first pipeline 1, the first pipeline 1 is discharged from the first outlet 3. The first hand valve 4 is set at the first inlet 2 for controlling the flow of organic waste water entering the first pipeline 1; the second hand valve 5 is set at the first outlet 3 , used to control the flow of organic wastewater flowing out of the fi...

Embodiment 2

[0080] This application also provides a method of using the pipeline descaling device, please refer to the attached figure 1 , the usage methods include:

[0081] Step 1: Close the first hand valve 4, the second hand valve 5, the third hand valve 6, and the fourth hand valve 7, open the fifth hand valve, and empty the first liquid in pipe 1;

[0082] Specifically, close the third hand valve 6 and the fourth hand valve 7 to prevent the cleaning liquid in the second pipeline from entering the first pipeline 1; close the first hand valve 4 and the The second hand valve 5 is used to prevent the organic wastewater from entering the first pipeline 1. Then, the fifth hand valve is opened, and the liquid in the first pipeline 1 is discharged from the fifth hand valve under the action of gravity.

[0083] Step 2: Open the third hand valve 6, the fourth hand valve 7, the filter 15, the first water pump 10, the second water pump 11, the heat exchange device 16, close the The fifth ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com