Method for preparing high-crystallinity AlN thin film by growing seed crystal layer through ALD (Atomic Layer Deposition)

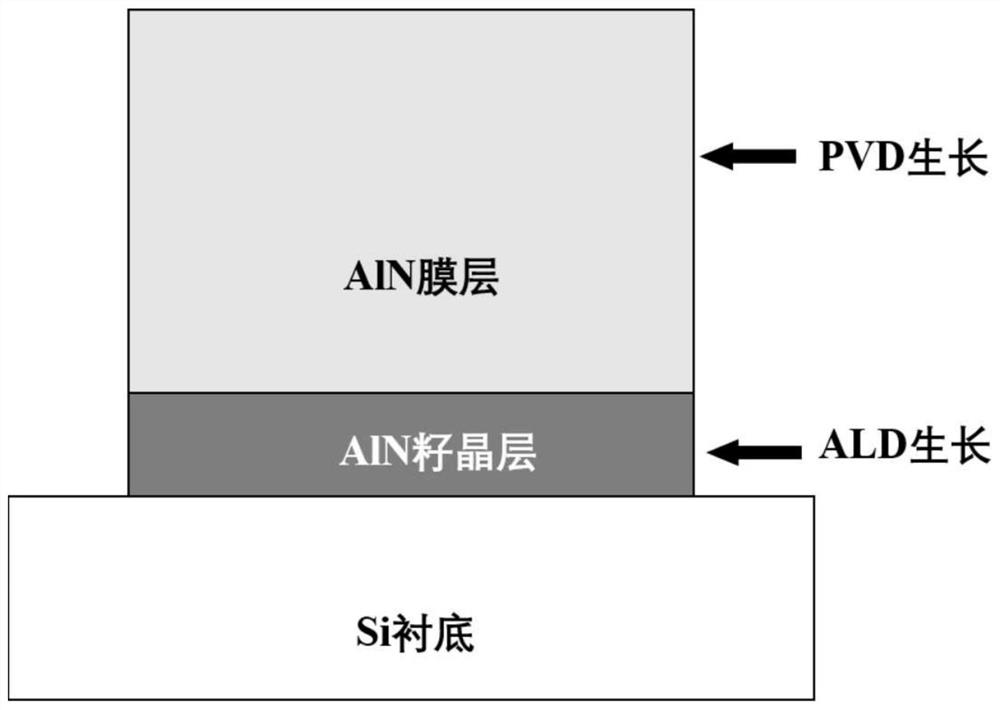

A seed layer and thin film technology, which is applied in the field of high crystallization AlN thin film preparation, can solve the problems of long preparation time, slow film growth rate and high cost, and achieve the effect of reducing deposition time and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, an ALD combined with PVD method is used to deposit an AlN thin film. During ALD deposition of the seed layer, trimethylaluminum (TMA) and NH 3 Alternative deposition of TMA and NH as reactive precursors for Al and N sources 3 The plasma is used to grow the AlN atomic layer. During the deposition process, each ALD cycle consists of four steps: (1) TMA pulse, (2) argon purge, (3) NH 3 Pulse, (4) Argon purge. Four steps are performed to deposit a thin film of one atomic layer.

[0040] Through the above description, the specific implementation steps of the invention are as follows:

[0041] Step 1: Substrate Cleaning

[0042] Prepare single crystal Si substrate: 4-inch substrate, polished on one side, cleaned by RCA standard process, then soaked in 5% hydrofluoric acid aqueous solution for 2 minutes to remove the surface oxide layer, finally blown dry with nitrogen, and put it into the ALD chamber.

[0043] Step 2: Growth of AlN seed layer by ALD ...

Embodiment 2

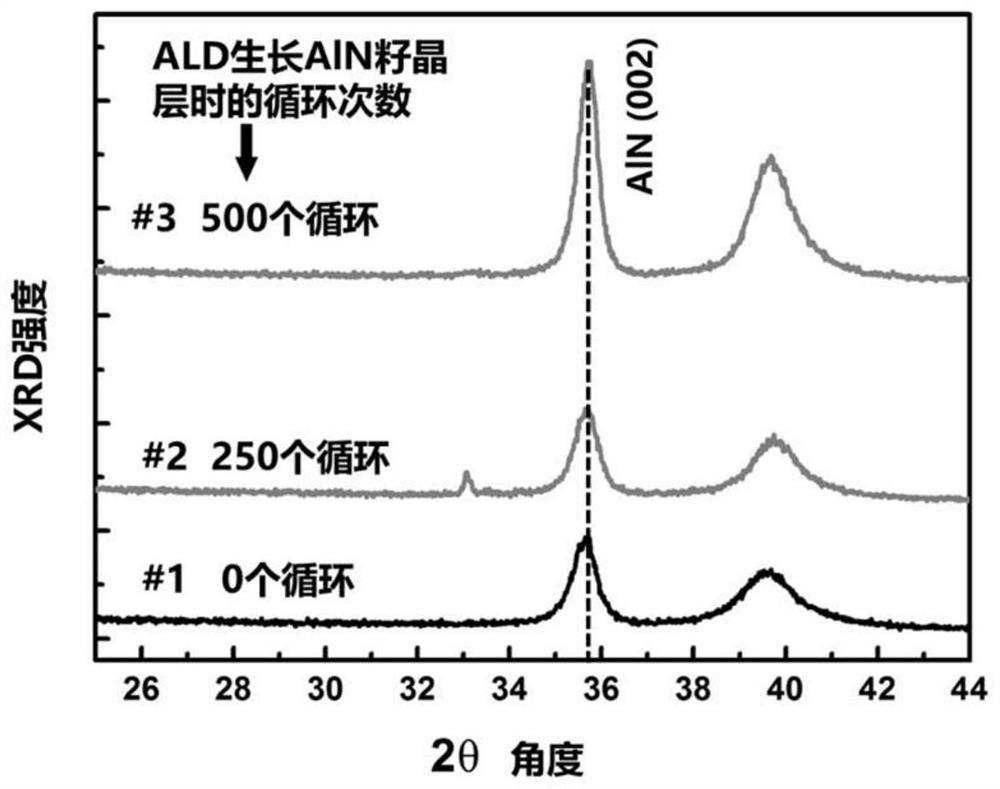

[0062] In step f in Example 1, steps b, c, d, and e are executed in cycles of 0, 250 and 500 times respectively to obtain AlN seed layers with different thicknesses, and then use PVD on the AlN seed layer with the same deposition process parameters A 1000nm AlN film layer is deposited to obtain AlN films with different crystallization degrees. as follows figure 2 As shown, the experiment proves that the c-axis orientation (002) crystal orientation of the finally prepared AlN thin film is enhanced with the increase of the number of cycles of ALD in growing the AlN seed layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com