Method for crystallizing and separating large-particle ammonium metavanadate from vanadium-containing solution

A technology for ammonium metavanadate and crystallization separation, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of non-scaling ammonium metavanadate, affecting the heat transfer effect of heat exchangers, and slow cooling rate , achieve the effects of shortening the crystallization time, good application prospects, and increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

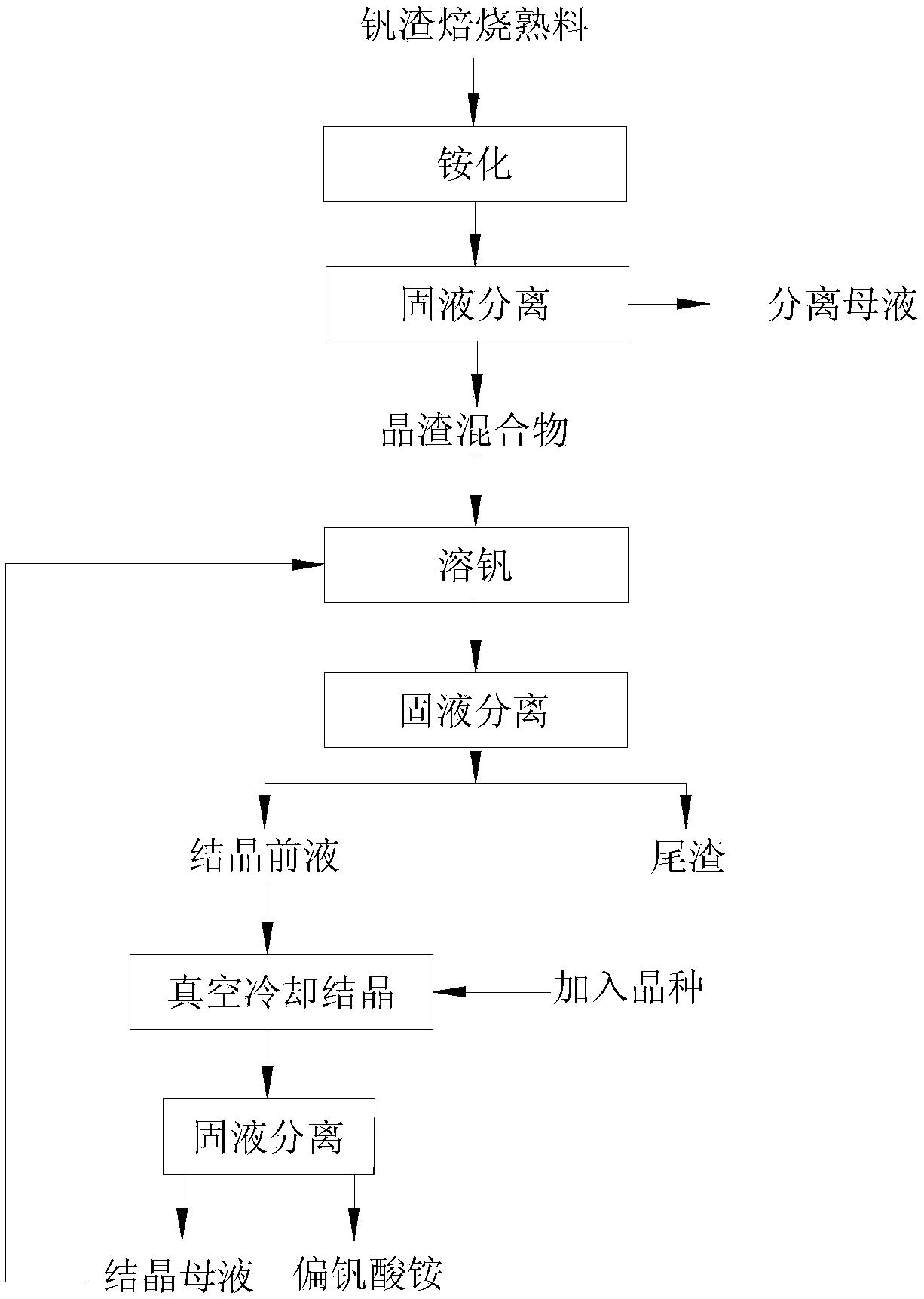

[0029] Such as figure 1 Shown, the technical process that the present invention crystallizes and separates large particle ammonium metavanadate from vanadium-containing solution can be:

[0030] (1) The vanadium-containing raw material roasting clinker is mixed with ammonium bicarbonate solution for ammonization reaction, the liquid-solid ratio is 0.2:1 (mass ratio), the concentration of ammonium bicarbonate is 50wt%, and the ammonization reaction temperature is 40°C. After melting, crystal slag mixed slurry is obtained;

[0031] (2) Mix the hot liquid with the crystalline slag mixture obtained in step (1), the liquid-solid ratio of the hot liquid and the crystalline slag mixture is 3:1 (mass ratio), heat it to 70°C for 30 minutes under stirring conditions, and make it react with All the ammonium metavanadate mixed with the slag phase was dissolved in water, and filtered at 70°C to obtain tailings and pre-crystallization liquid. The concentration of ammonium metavanadate in t...

Embodiment 2

[0035] Transfer the 85°C vanadium-containing solution (the concentration of ammonium metavanadate is 30g / L) obtained after ammonium leaching of vanadium-containing clinker into a vacuum crystallizer for cooling and crystallization, and adjust the vacuum to 0.066MPa; when the temperature reaches 60 When the temperature reaches 58°C, add 0.75% ammonium metavanadate mass seed crystals, and a small amount of crystals are precipitated instantly; when the temperature reaches 50°C, adjust the vacuum degree to 0.11MPa; when the temperature reaches 39°C When the crystallization is completed, the ammonium metavanadate crystal and the crystallization mother liquor are obtained by filtering after the crystallization is completed.

[0036] The total time for cooling from 85°C to 39°C is 30 minutes, the average particle size of the crystals is 300 μm, and no scaling phenomenon was found on the inner wall of the crystallizer during the crystallization process.

Embodiment 3

[0038] Transfer the 90°C vanadium-containing purification solution with a concentration of 40g / L of ammonium metavanadate into a vacuum crystallizer for cooling and crystallization, and adjust the vacuum degree to 0.06MPa; when the temperature reaches 60°C, add 1% ammonium metavanadate by mass When the temperature reaches 50°C, the vacuum degree is adjusted to 0.15MPa; when the temperature is 35°C, the crystallization is completed, and after the crystallization is completed, filter to obtain ammonium metavanadate crystals and crystallization mother liquor.

[0039] The total time for cooling from 90°C to 35°C is 33 minutes, the average particle size of the crystals is 400 μm, and no scaling phenomenon was found on the inner wall of the crystallizer during the crystallization process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com