A kind of method utilizing fly ash to prepare aluminum chloride

A technology of fly ash and crystalline aluminum chloride, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of reduced equipment corrosion, low impurity content, equipment corrosion, etc., to reduce process energy consumption, high purity, high Efficiency transforms the effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

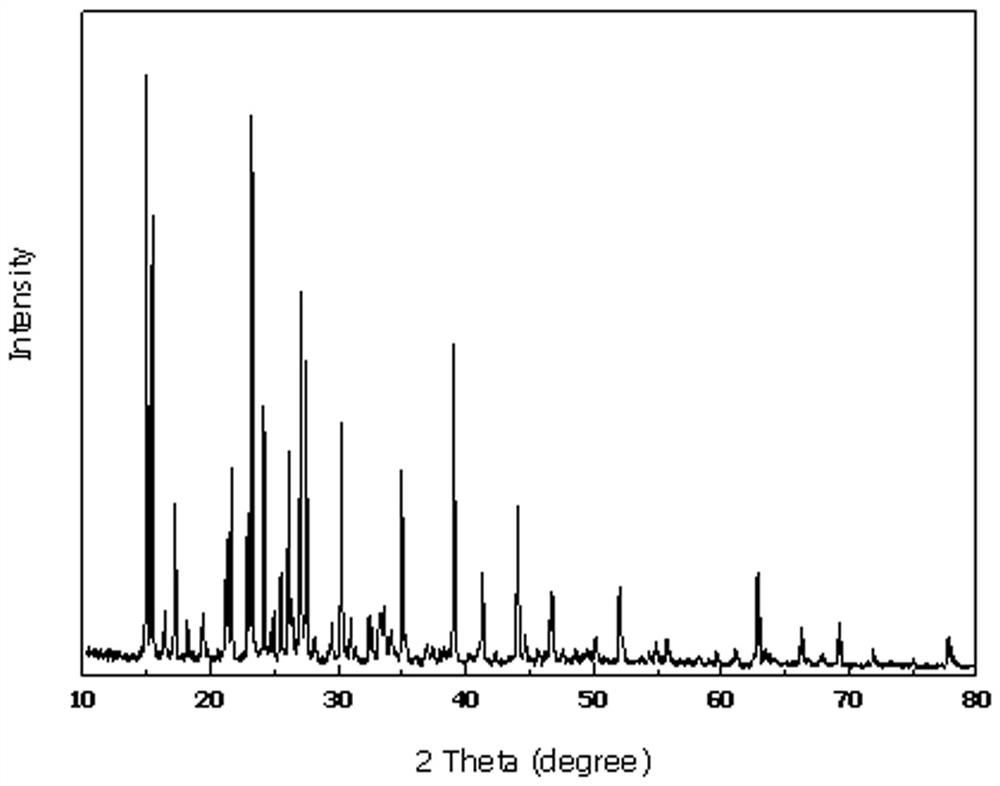

Image

Examples

Embodiment 1

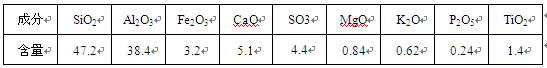

[0033] Take 1kg of fly ash ground to 100~200 mesh, add 0.6kg of water, mix thoroughly in a well-insulated 5L enamel tank, take 2kg of 98% concentrated sulfuric acid and add it to the enamel reaction kettle, seal the kettle body, and adjust the pressure to 0.3 MPa, temperature is 140°C, heat preservation reaction for 6h; when the pressure of the reaction kettle drops to atmospheric pressure, add 1.2kg of hot water at 90°C, filter it with a plate and frame filter press, put the obtained aluminum sulfate solution into an enamel evaporation tank; add Aluminum hydroxide adjusts the remaining acid, and after stabilization, the measured pH is 2.3. Use the residual heat of the solution and the neutralization heat released by aluminum hydroxide to evaporate and concentrate, and naturally cool to 30°C for separation to obtain crystalline aluminum sulfate; heat the aluminum sulfate at 80°C Dissolve in water, keep warm and stir for 3 hours, then cool to 50°C, stand still and filter to obta...

Embodiment 2

[0035] Take 1kg of fly ash ground to 100~200 mesh, add 1.5kg of water, mix thoroughly in a well-insulated 5L enamel tank, take 3kg of 98% concentrated sulfuric acid and add it to the enamel reaction kettle, seal the kettle body, and adjust the pressure to 0.4 MPa, temperature is 160°C, heat preservation reaction for 5h; when the pressure of the reaction kettle drops to atmospheric pressure, add 0.4kg of hot water at 90°C, filter it with a plate and frame filter press, put the obtained aluminum sulfate solution into an enamel evaporation tank; add Aluminum hydroxide adjusts the remaining acid, and after stabilization, the measured pH is 2.2. Use the residual heat of the solution and the neutralization heat released by aluminum hydroxide to evaporate and concentrate, and naturally cool to 30°C for separation to obtain crystalline aluminum sulfate; heat the aluminum sulfate at 80°C Dissolve in water, keep warm and stir for 3.5h, then cool to 55°C, stand still and filter to obtain ...

Embodiment 3

[0037]Take 20kg of fly ash ground to 100~200 mesh, add 20kg of water, mix thoroughly in a well-insulated 50L enamel reaction kettle, take 25kg of 98% concentrated sulfuric acid into the enamel kettle, seal the kettle body, and adjust the pressure to 0.45MPa , the temperature is 160°C, heat preservation reaction for 6h; when the pressure of the reaction kettle drops to atmospheric pressure, add 22kg of hot water at 90°C, filter it with a plate and frame press, put the obtained aluminum sulfate solution into an enamel evaporation tank; add aluminum hydroxide Adjust the remaining acid, and after stabilization, the measured pH is 2.1. Use the residual heat of the solution and the neutralization heat released by aluminum hydroxide to evaporate and concentrate, and naturally cool to 30°C to separate to obtain crystalline aluminum sulfate; dissolve the aluminum sulfate with hot water at 80°C, And keep stirring for 5 hours, then cool to 60°C, stand still, and filter to obtain refined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com