Process for solving problem of high evaporation boiling point of ammonia chloride by using MVR

An ammonium chloride and boiling point technology, applied in the difficult process field, can solve the problems of decomposition of ammonium chloride, high ammonia nitrogen content in distilled water, discount of ammonium chloride recovery rate, etc., to reduce evaporation temperature, stabilize system operation, and solve recovery efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

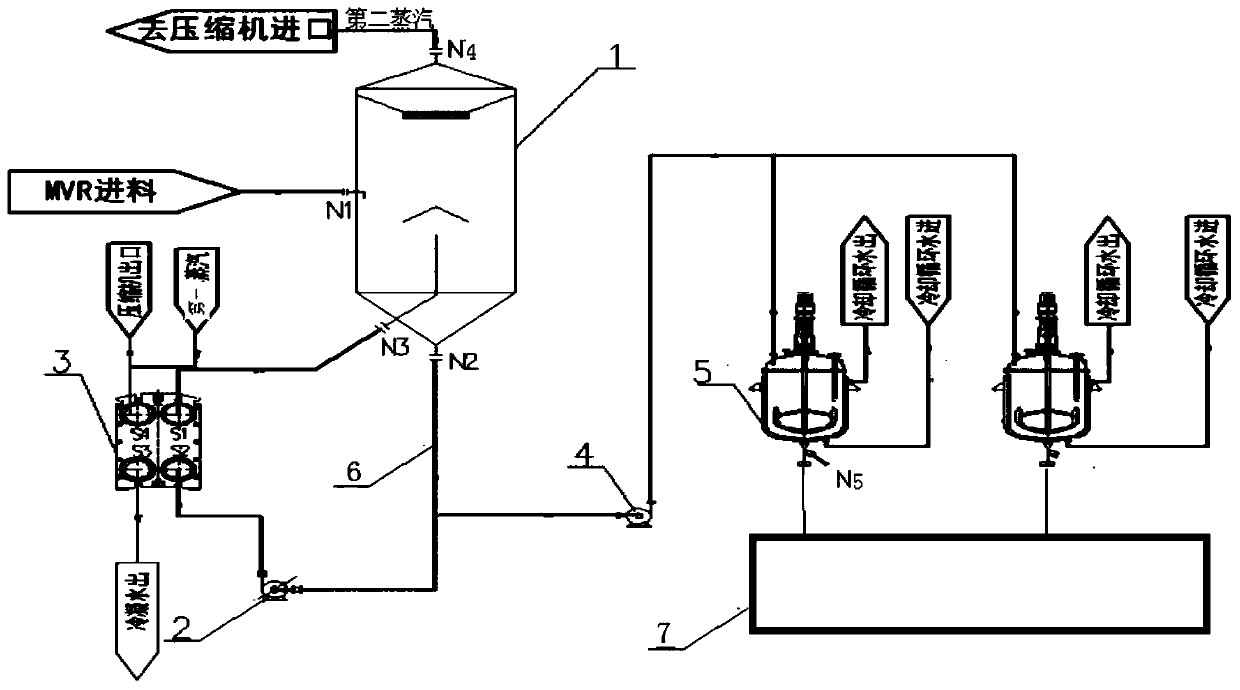

[0022] A kind of technology that solves the difficult problem that ammonium chloride utilizes MVR evaporation boiling point to be higher, comprises the steps:

[0023] a. The ammonium chloride waste water enters the MVR feed system after being preheated, and the MVR feed system is connected with the preheated ammonium chloride waste water inlet N1 in the middle of the crystallization separator 1, and the preheated ammonium chloride waste liquid enters the crystallization through the N1 inlet separator 1;

[0024] b, the top of the crystallizer 1 is provided with a secondary steam outlet N4, N4 is sealed and connected with the compressor inlet through the pipeline 6, and the compressor takes out the secondary steam of the preheated ammonium chloride waste water to keep the air pressure in the crystallizer 1 at 65KPa, The temperature is 85°C, and the secondary steam passes through the ammonium chloride wastewater in step a to preheat the ammonium chloride wastewater, reduce the ...

Embodiment 2

[0032] A kind of technology that solves the difficult problem that ammonium chloride utilizes MVR evaporation boiling point to be higher, comprises the steps:

[0033] a. The ammonium chloride waste water enters the MVR feed system after being preheated, and the MVR feed system is connected with the preheated ammonium chloride waste water inlet N1 in the middle of the crystallization separator 1, and the preheated ammonium chloride waste liquid enters the crystallization through the N1 inlet separator 1;

[0034] b, the top of the crystallizer 1 is provided with a secondary steam outlet N4, N4 is sealed and connected to the compressor inlet through the pipeline 6, and the compressor takes out the secondary steam of the preheated ammonium chloride waste water to keep the air pressure in the crystallizer 1 at 85KPa, The temperature is 89°C, and the secondary steam passes through the ammonium chloride wastewater in step a to preheat the ammonium chloride wastewater, reduce the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com