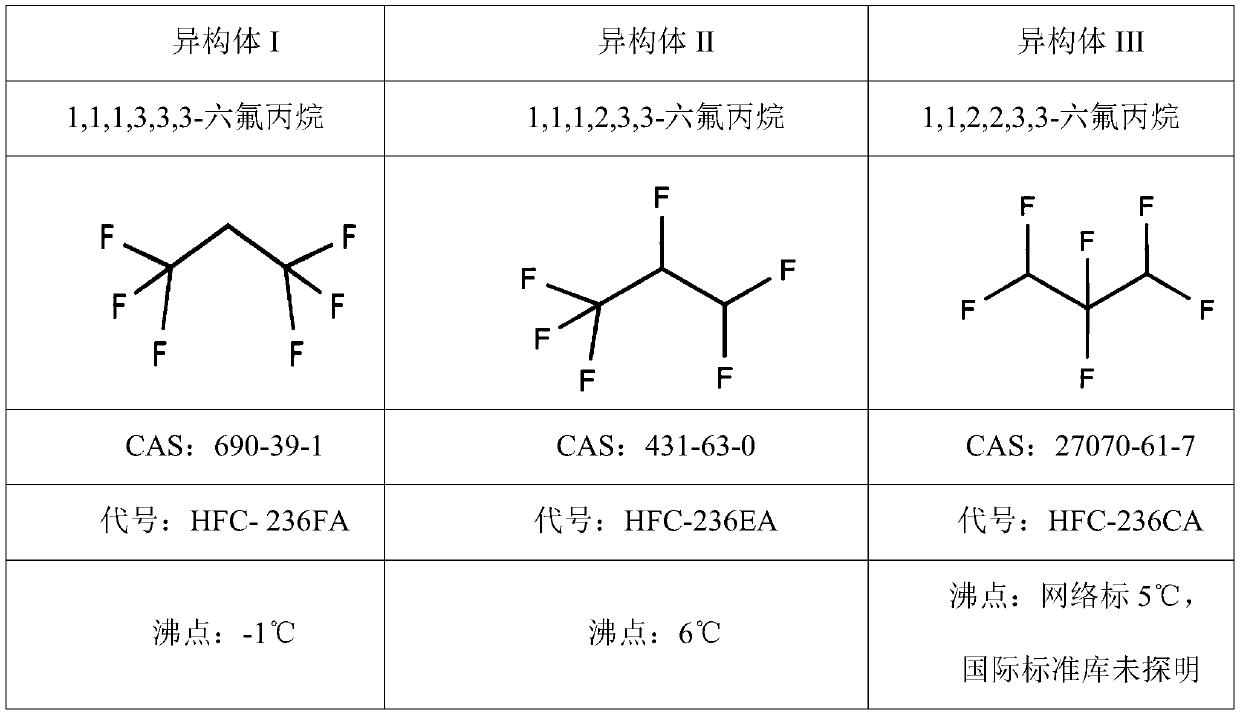

Separation method of high-purity electronic-grade hexafluoropropane isomer

A technology of isomers and hexafluoropropane, which is applied in the field of separation of high-purity electronic grade hexafluoropropane isomers, can solve the problems of separation, small differences in structure and boiling point, etc., and achieves high directional purification depth, Stable process performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

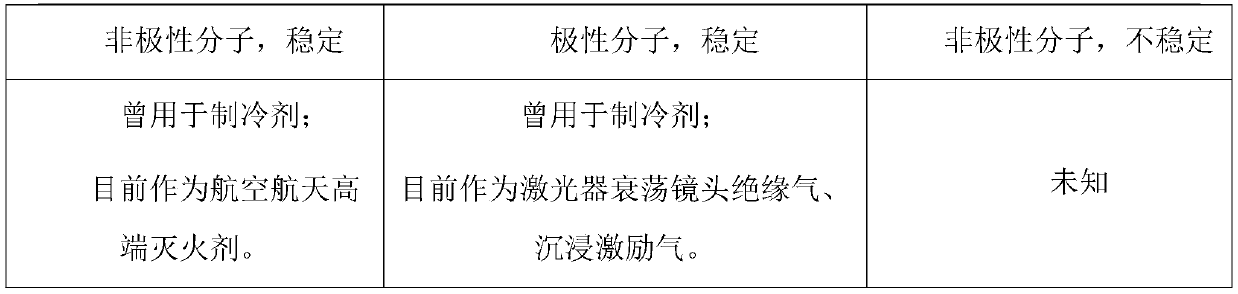

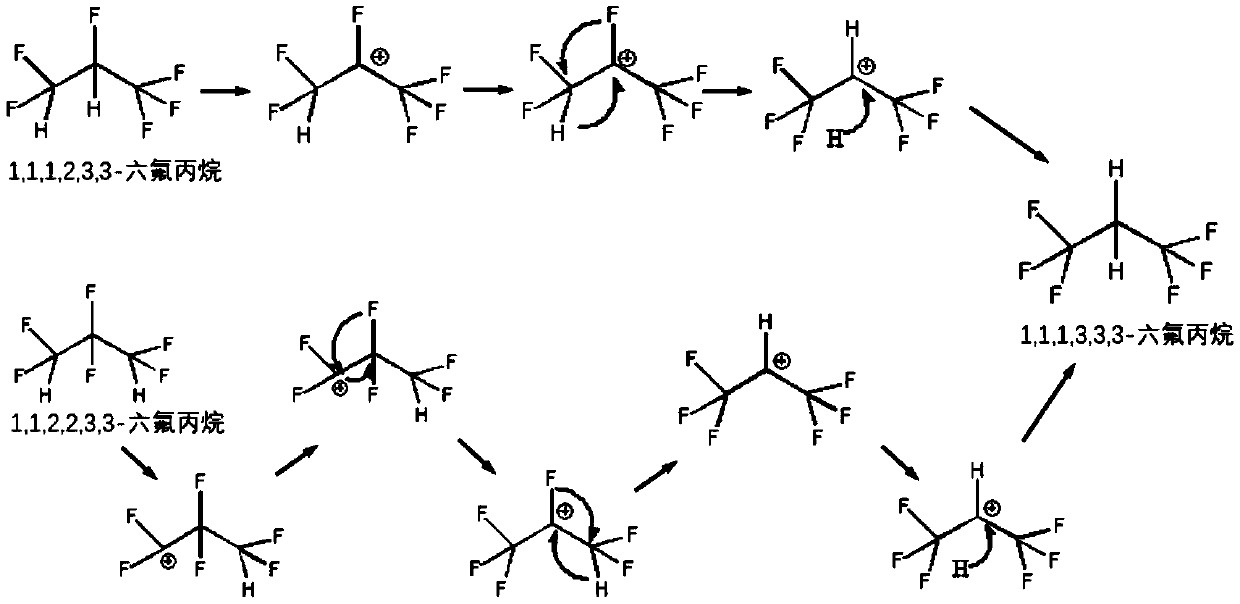

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for separating isomers of high-purity electronic grade hexafluoropropane, comprising the steps of:

[0045] S1: Pass the raw material into the water washing tower for water washing and deacidification;

[0046] S2: Pass the washed raw material into the adsorption tower for dehydration, and the adsorption material in the adsorption tower is 3A adsorbent;

[0047] S3: Pass the dehydrated raw material into the catalytic conversion tower, the form of the catalytic conversion tower is a fixed bed reactor, the surface active component of the catalyst filled therein is platinum, the loading content is 0.2wt%, and the carrier is alumina, The silicon-aluminum ratio of the carrier is 5; the gas space velocity of the catalytic conversion tower is 50h -1 , the specific surface area is 200m 2 / g, the catalytic conversion temperature is 400°C, and the catalytic conversion pressure is 0.2 MPa.

[0048] S4: Rectification to remove other impurities. The rectification tower s...

Embodiment 2

[0050] A method for separating isomers of high-purity electronic grade hexafluoropropane, comprising the steps of:

[0051] S1: Pass the raw material into the water washing tower for water washing and deacidification;

[0052] S2: Pass the washed raw material into the adsorption tower for dehydration, and the adsorption material in the adsorption tower is 4A adsorbent;

[0053] S3: Pass the dehydrated raw material into the catalytic conversion tower, the form of the catalytic conversion tower is a fixed bed reactor, the surface active component of the catalyst filled therein is platinum, the loading content is 0.3wt%, and the carrier is alumina, The silicon-aluminum ratio of the carrier is 5; the gas space velocity of the catalytic conversion tower is 80h -1 , the specific surface area is 300m 2 / g, the catalytic conversion temperature is 450°C, and the catalytic conversion pressure is 0.2 MPa.

[0054] S4: Rectification to remove other impurities. The rectification tower s...

Embodiment 3

[0056] A method for separating isomers of high-purity electronic grade hexafluoropropane, comprising the steps of:

[0057] S1: Pass the raw material into the water washing tower for water washing and deacidification;

[0058] S2: Pass the washed raw material into the adsorption tower for dehydration, and the adsorption material in the adsorption tower is 4A adsorbent;

[0059] S3: Pass the dehydrated raw material into the catalytic conversion tower. The catalytic conversion tower is in the form of a fixed bed reactor. The surface active component of the catalyst filled in it is platinum, the loading content is 0.5wt%, and the carrier is alumina thin stone , the silicon-aluminum ratio of the carrier is 8; the gas space velocity of the catalytic conversion tower is 100h -1 , the specific surface area is 350m 2 / g, the catalytic conversion temperature is 480°C, and the catalytic conversion pressure is 0.2 MPa.

[0060] S4: Rectification to remove other impurities. The rectifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com