Method for producing iron concentrate by roasting, ore grinding and magnetic separation in refractory limonite stage

A technology of ore grinding and magnetic separation, limonite, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as difficult to effectively process limonite resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

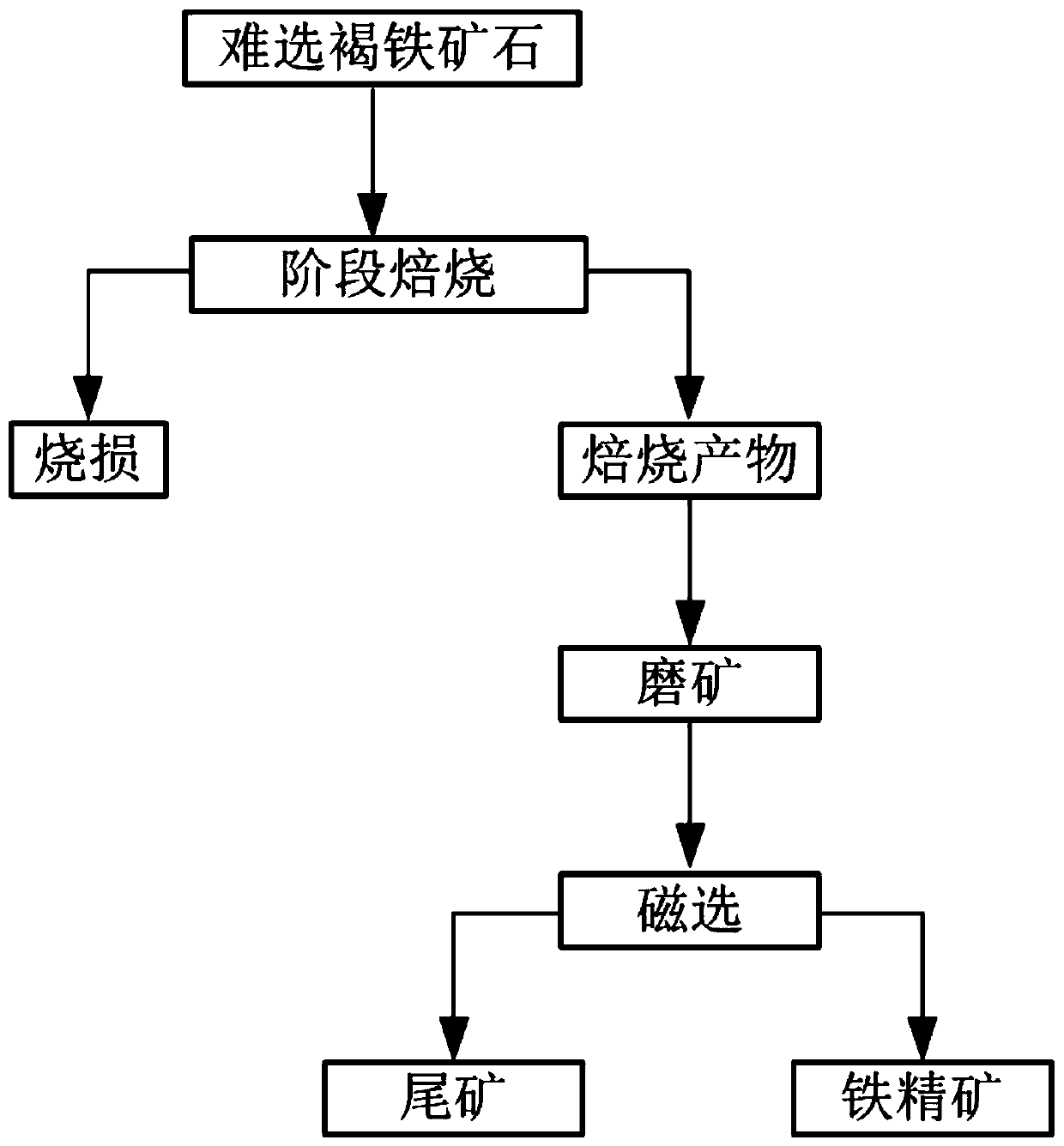

[0042] Process such as figure 1 shown;

[0043] The refractory limonite (refractory limonite) is ground to a particle size of -0.074mm, accounting for 68.75% of the total mass, and made into iron ore powder; the iron grade of the refractory limonite is 55.88%, and it contains Al 2 o 3 7.28%, SiO 2 3.01%, P0.088%, S 0.028%, crystal water 8.50%;

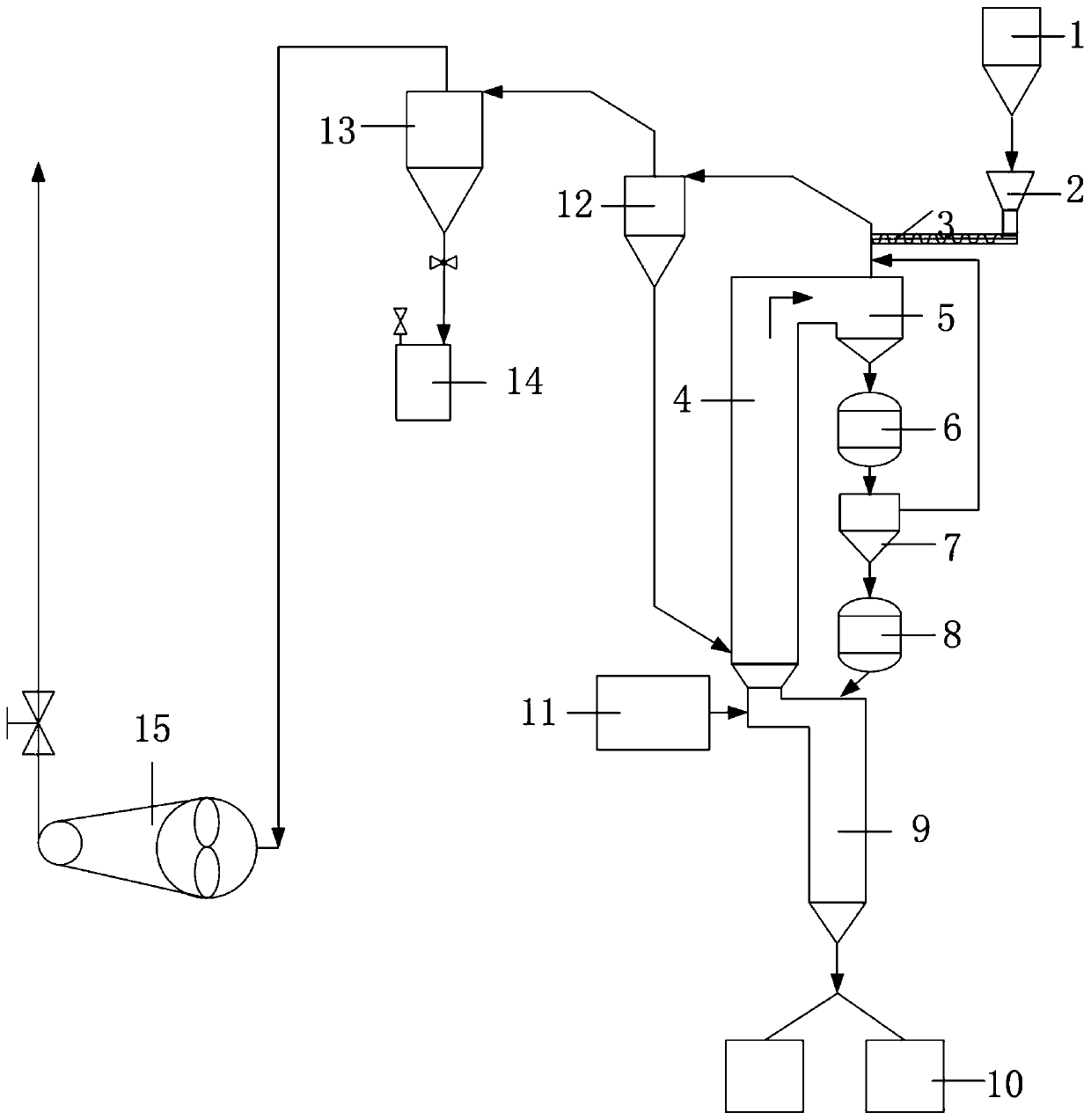

[0044] The stage roasting device is used to transport the iron ore powder to the first-stage cyclone separator through the screw feeder, and the material after the primary cyclone separation enters the lower part of the heating furnace from the discharge port; Air and gas are fed into the device. After the gas is burned, high-temperature gas is formed and enters the heating furnace. The material entering the heating furnace is heated to 850 ° C. Under negative pressure, it enters the secondary cyclone separator for secondary cyclone separation under the action of air flow; enters the heating furnace The residence time of the fur...

Embodiment 2

[0051] Method is with embodiment 1, and difference is:

[0052] (1) Grinding the refractory limonite to a particle size of -0.074mm accounts for 95.44% of the total mass to make iron ore powder; the iron grade of the refractory limonite is 56.58%, and contains Al by mass percentage 2 o 3 7.81%, SiO 2 3.02%, P 0.082%, S 0.038%, crystal water 6.88%;

[0053] (2) The material entering the heating furnace is heated to 750°C, and the residence time of the material entering the heating furnace in the heating furnace is 10s;

[0054] (3) Dehydration at 550°C, the residence time of solid material in the dehydration reactor is 10min;

[0055] (4) Reduction reaction at 460°C; residence time in reduction roasting furnace is 40min;

[0056] (5) The temperature drops to 200°C and is discharged from the cooler; the residence time of the reduced material in the cooler is 40s;

[0057] (6) Grinding the roasted material until the particle size is -0.074mm accounts for 93% of the total m...

Embodiment 3

[0060] Method is with embodiment 1, and difference is:

[0061] (1) Grinding the refractory limonite to a particle size of -0.074mm accounts for 76.8% of the total mass to make iron ore powder; the iron grade of the refractory limonite is 53.7%, containing Al by mass percentage 2 o 3 7.5%, SiO 2 3.7%, P 0.085%, S 0.036%, crystal water 4.52%;

[0062] (2) The material entering the heating furnace is heated to 800°C, and the residence time of the material entering the heating furnace in the heating furnace is 8s;

[0063] (3) Dehydration at 600°C, the residence time of solid materials in the dehydration reactor is 7min;

[0064] (4) Reduction reaction at 490°C; residence time in reduction roasting furnace is 20min;

[0065] (5) The temperature drops to 250°C and is discharged from the cooler; the residence time of the reduced material in the cooler is 30s;

[0066] (6) Grinding the roasted material until the particle size is -0.074mm accounts for 95% of the total mass, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com