Roasting device for carbon material processing

A roasting device and carbon material technology, which are applied in the petroleum industry, lighting and heating equipment, inorganic chemistry, etc., can solve the problems of poor roasting effect of activated carbon, and achieve the effect of avoiding excessive adhesion and enhancing roasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

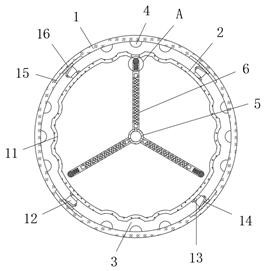

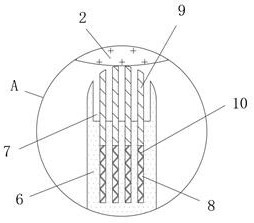

[0027]ReferenceFigure 1-3 , A roasting device for carbon material processing, comprising a heat preservation cylinder 1, a baking cylinder 2 is arranged inside the heat preservation cylinder 1, and an auxiliary cavity 3 is formed between the inner wall of the heat preservation cylinder 1 and the outer wall of the baking cylinder 2. The inner wall is fixed with a plurality of heating elements 4, both ends of the heat preservation cylinder 1 are provided with sealing cover plates, the intermediate position between the inner walls of the two ends of the roasting cylinder 2 is rotatably connected with a fixing element 5, and one end of the fixing element 5 is drivingly connected with a drive For the motor, a plurality of dispersing members 6 are fixed on the outer circumferential wall of the fixing member 5, and one end of the dispersing member 6 away from the fixing member 5 is provided with a connecting groove 7 penetrating at both ends, and the inner wall of one end of the connecting...

Embodiment 2

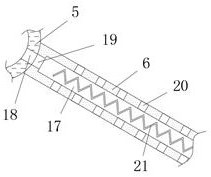

[0033]ReferenceFigure 1-4, A roasting device for carbon material processing, the outer wall of the fixing member 5 is provided with a plurality of dispersing members 6 distributed in an annular array, and each group of dispersing members 6 is provided with two dispersing members 6 distributed on both ends of the fixing member 5, and two adjacent groups of dispersing members The pieces 6 are arranged at intervals, and a plurality of drainage pieces 22 of corrugated structure are fixed between the two dispersing pieces 6 on the same vertical surface, and the drainage piece 22 is formed by two arc-shaped drainage plates. , The two drainage plates are arched inward, and there are gaps on both sides between the two drainage plates.

[0034]When the present invention is in use: during the rotation of the drainage member 22 with the dispersing member 6, the inwardly concave arc surface of the drainage plate and the gap between the two drainage plates are used to move the activated carbon at v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com