A method for producing iron concentrate by stage roasting, grinding and magnetic separation of refractory limonite

A technology for grinding, magnetic separation, and limonite, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as difficulty in effectively processing limonite resources, and achieve huge economic and social benefits. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

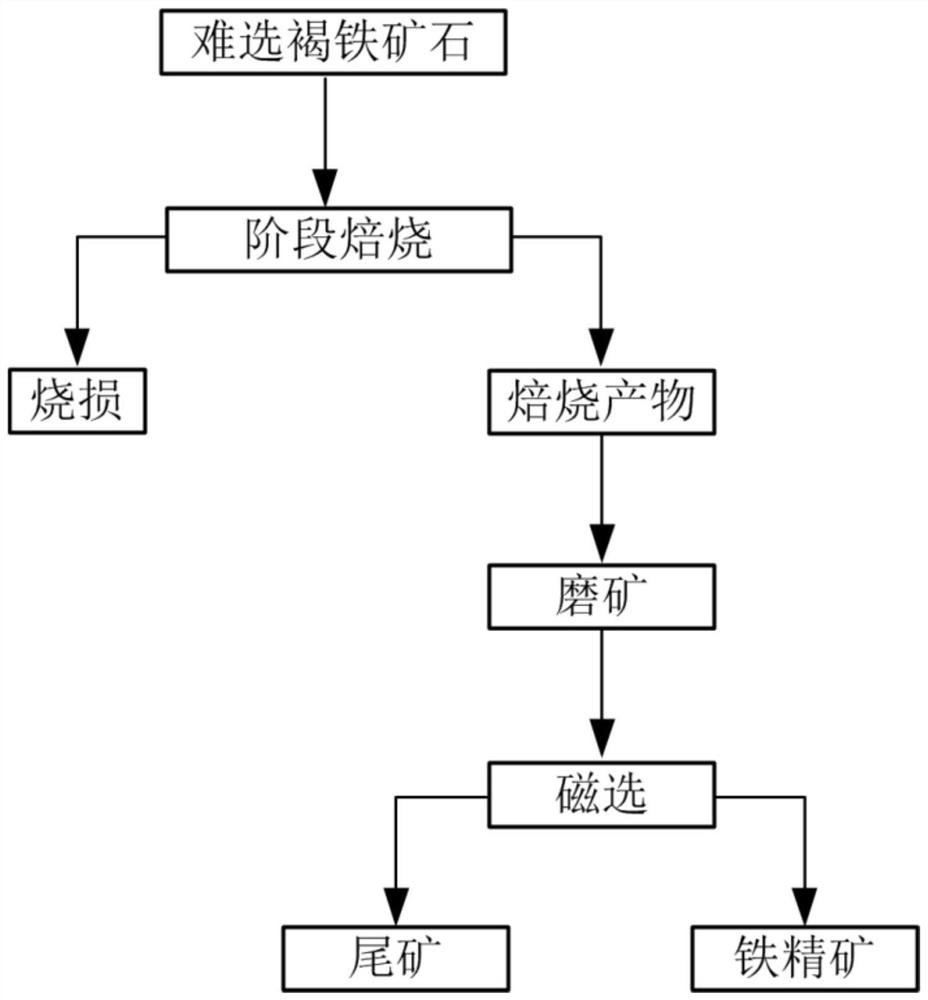

[0042] Process such as figure 1 shown;

[0043] The refractory limonite (refractory limonite) is ground to a particle size of -0.074mm, accounting for 68.75% of the total mass, and made into iron ore powder; the iron grade of the refractory limonite is 55.88%, and it contains Al 2 o 3 7.28%, SiO 2 3.01%, P0.088%, S 0.028%, crystal water 8.50%;

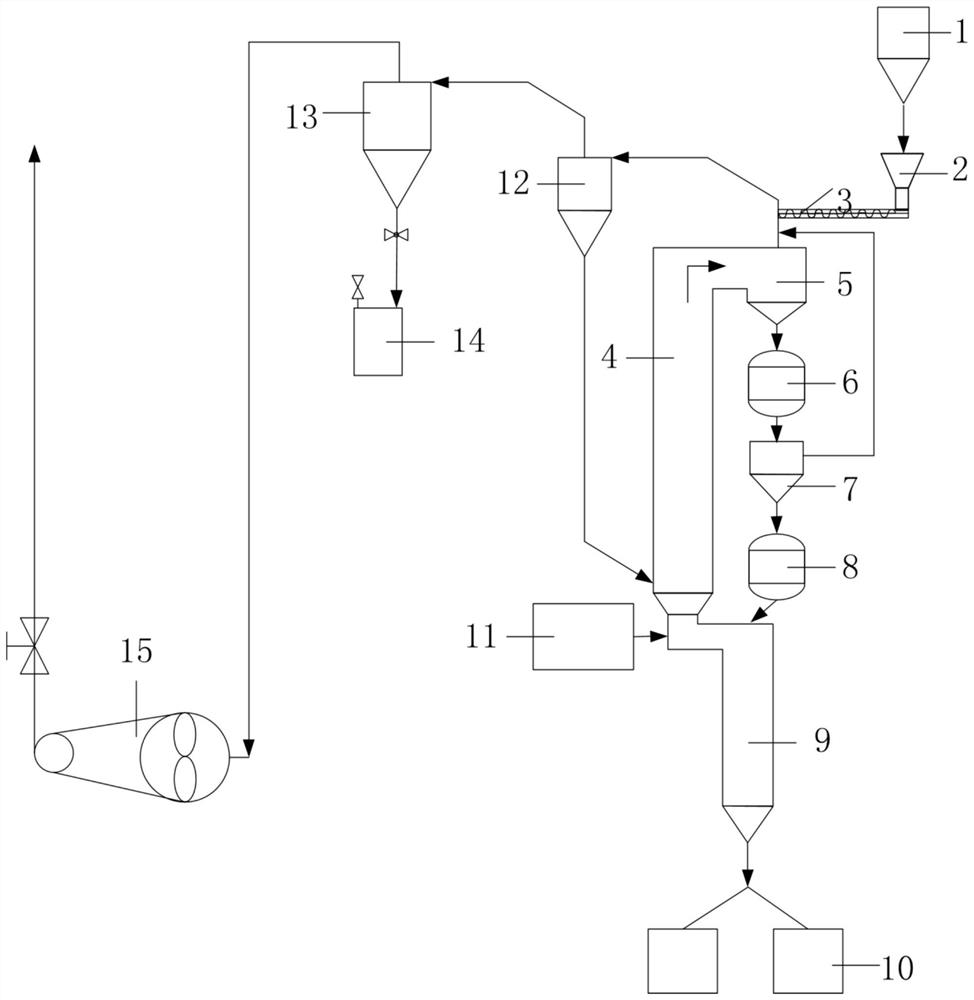

[0044] The stage roasting device is used to transport the iron ore powder to the first-stage cyclone separator through the screw feeder, and the material after the primary cyclone separation enters the lower part of the heating furnace from the discharge port; Air and gas are fed into the device. After the gas is burned, high-temperature gas is formed and enters the heating furnace. The material entering the heating furnace is heated to 850 ° C. Under negative pressure, it enters the secondary cyclone separator for secondary cyclone separation under the action of air flow; enters the heating furnace The residence time of the fur...

Embodiment 2

[0051] Method is with embodiment 1, and difference is:

[0052] (1) Grinding the refractory limonite to a particle size of -0.074mm accounts for 95.44% of the total mass to make iron ore powder; the iron grade of the refractory limonite is 56.58%, and contains Al by mass percentage 2 o 3 7.81%, SiO 2 3.02%, P 0.082%, S 0.038%, crystal water 6.88%;

[0053] (2) The material entering the heating furnace is heated to 750°C, and the residence time of the material entering the heating furnace in the heating furnace is 10s;

[0054] (3) Dehydration at 550°C, the residence time of solid material in the dehydration reactor is 10min;

[0055] (4) Reduction reaction at 460°C; residence time in reduction roasting furnace is 40min;

[0056] (5) The temperature drops to 200°C and is discharged from the cooler; the residence time of the reduced material in the cooler is 40s;

[0057] (6) Grinding the roasted material until the particle size is -0.074mm accounts for 93% of the total m...

Embodiment 3

[0060] Method is with embodiment 1, and difference is:

[0061] (1) Grinding the refractory limonite to a particle size of -0.074mm accounts for 76.8% of the total mass to make iron ore powder; the iron grade of the refractory limonite is 53.7%, containing Al by mass percentage 2 o 3 7.5%, SiO 2 3.7%, P 0.085%, S 0.036%, crystal water 4.52%;

[0062] (2) The material entering the heating furnace is heated to 800°C, and the residence time of the material entering the heating furnace in the heating furnace is 8s;

[0063] (3) Dehydration at 600°C, the residence time of solid materials in the dehydration reactor is 7min;

[0064] (4) Reduction reaction at 490°C; residence time in reduction roasting furnace is 20min;

[0065] (5) The temperature drops to 250°C and is discharged from the cooler; the residence time of the reduced material in the cooler is 30s;

[0066] (6) Grinding the roasted material until the particle size is -0.074mm accounts for 95% of the total mass, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com