Construction method for canal penetration drainage of underground utility pipe gallery

A technology of integrated pipe gallery and construction method, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as delay in construction period, difficult coordination, and project shutdown, and achieve increased safety and reliability, overall stable operation, The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

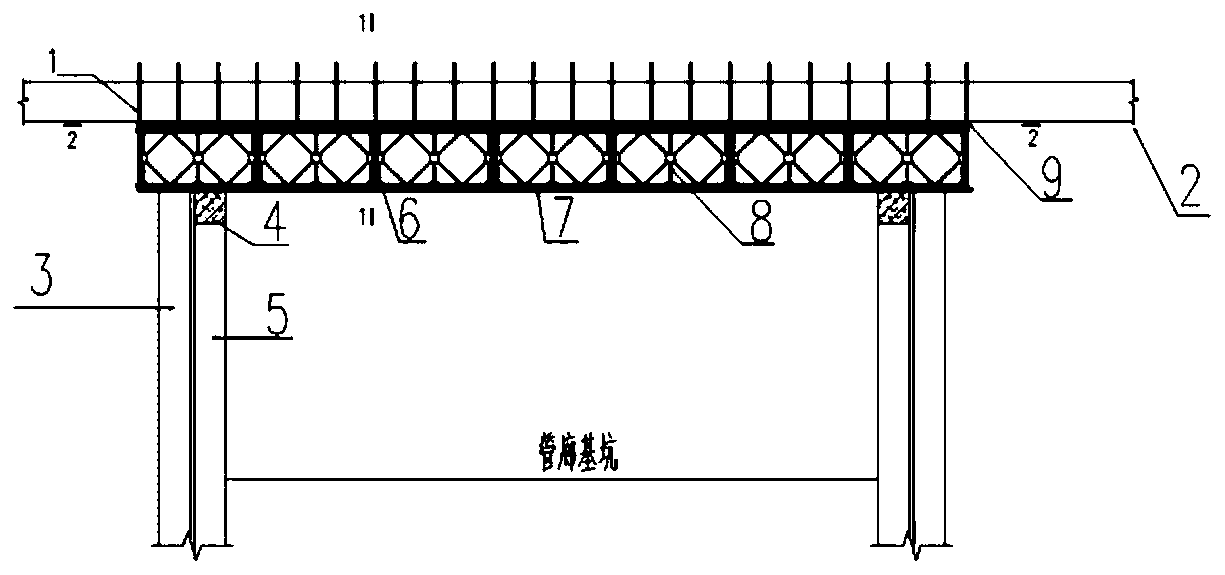

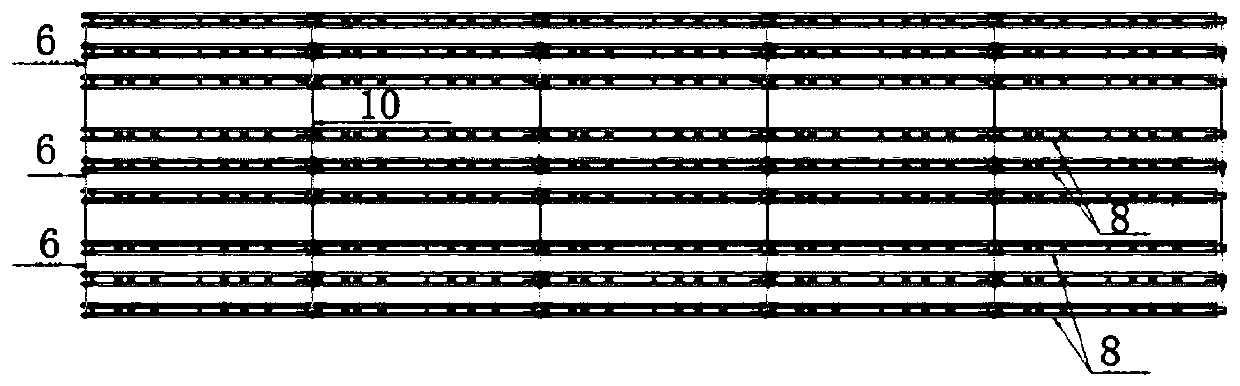

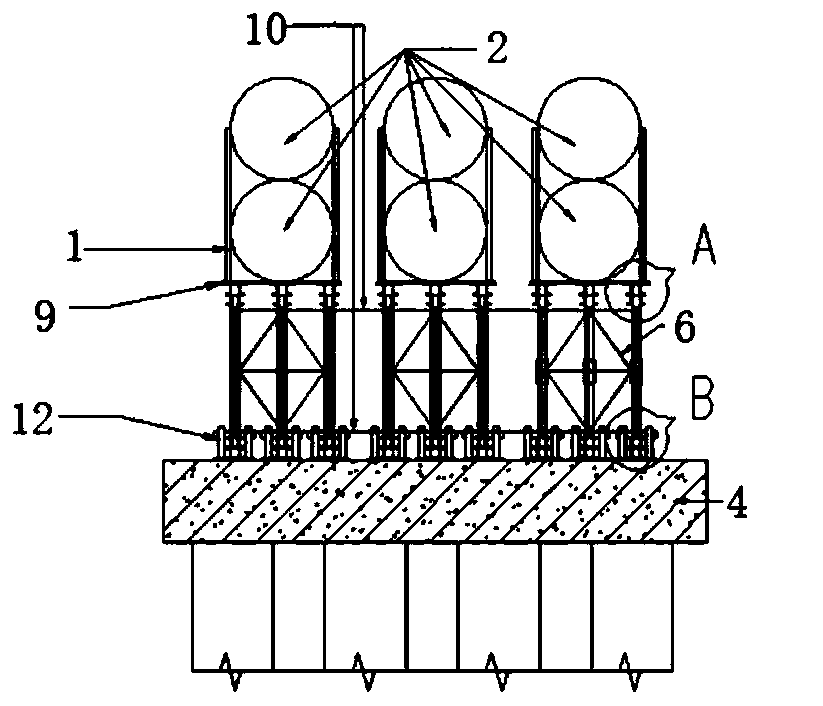

[0030] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-6 As shown, a construction method for drainage of underground comprehensive pipe gallery through river channels, including the following steps:

[0031] Step 1. Foundation pit support: In order to ensure the water blocking effect of the foundation pit of the canal and the requirements for the bearing capacity of the later Bailey frame support, the type of foundation pit support is to set a number of cast-in-place piles 5 from the inside to the outside on both sides of the pipe gallery foundation pit, and the cast-in-place piles 5 wrapping the high-pressure rotary grouting pile 3, pouring the crown beam 4 on the top of the cast-in-place pile 5;

[0032] Step 2. Construction of steel conduit 2 and Bailey frame support system: Build water-passing steel conduit 2 and Bailey frame support at the parallel position where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com