Standing curing equipment

A curing equipment and standing technology, which is applied in the direction of mechanical equipment, conveyor control devices, and devices for coating liquid on the surface, can solve problems such as low operating efficiency, labor costs, and inability to effectively prevent product pollution. Prevent pollution, increase storage capacity, and realize the effect of automatic flow operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

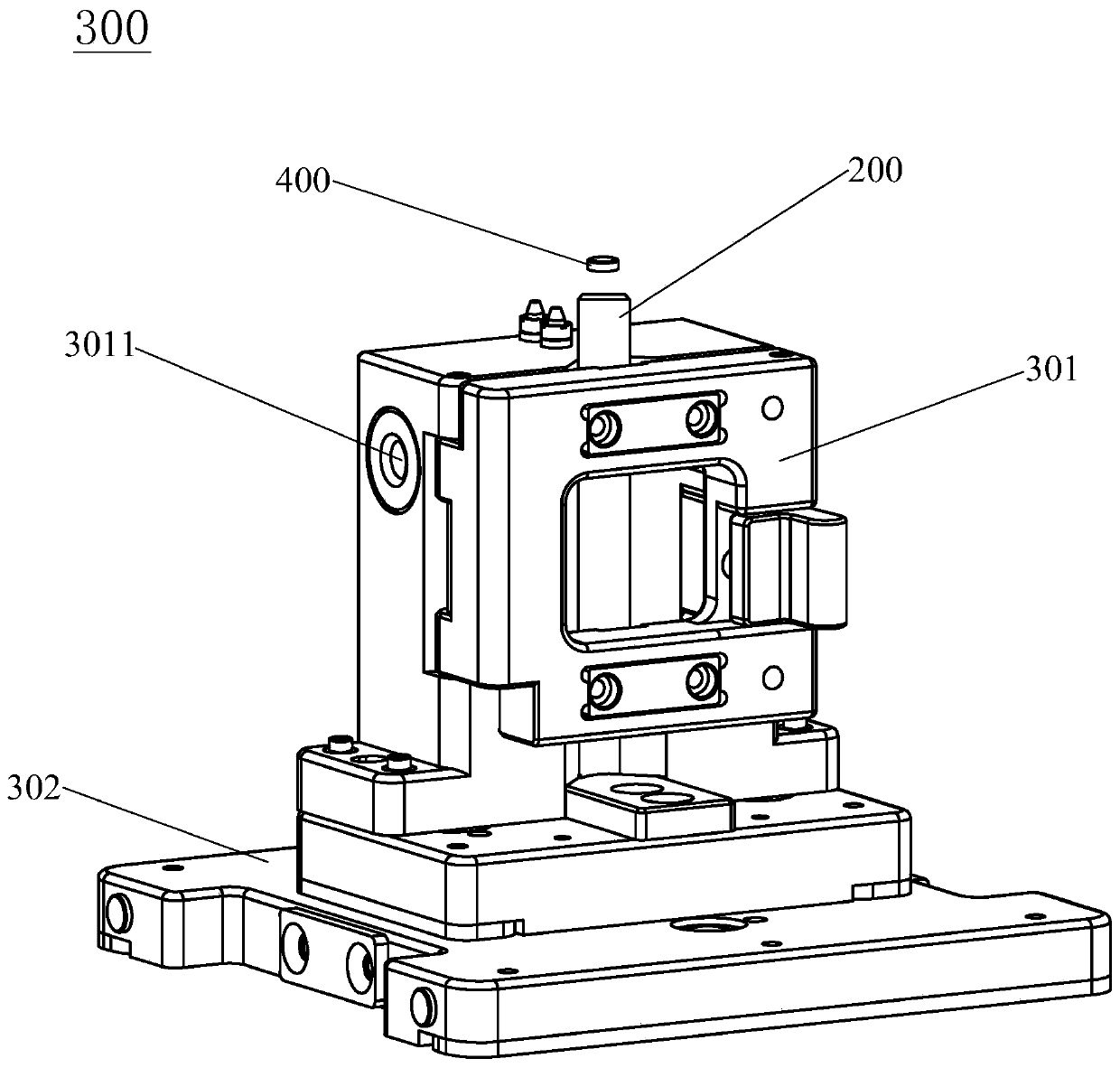

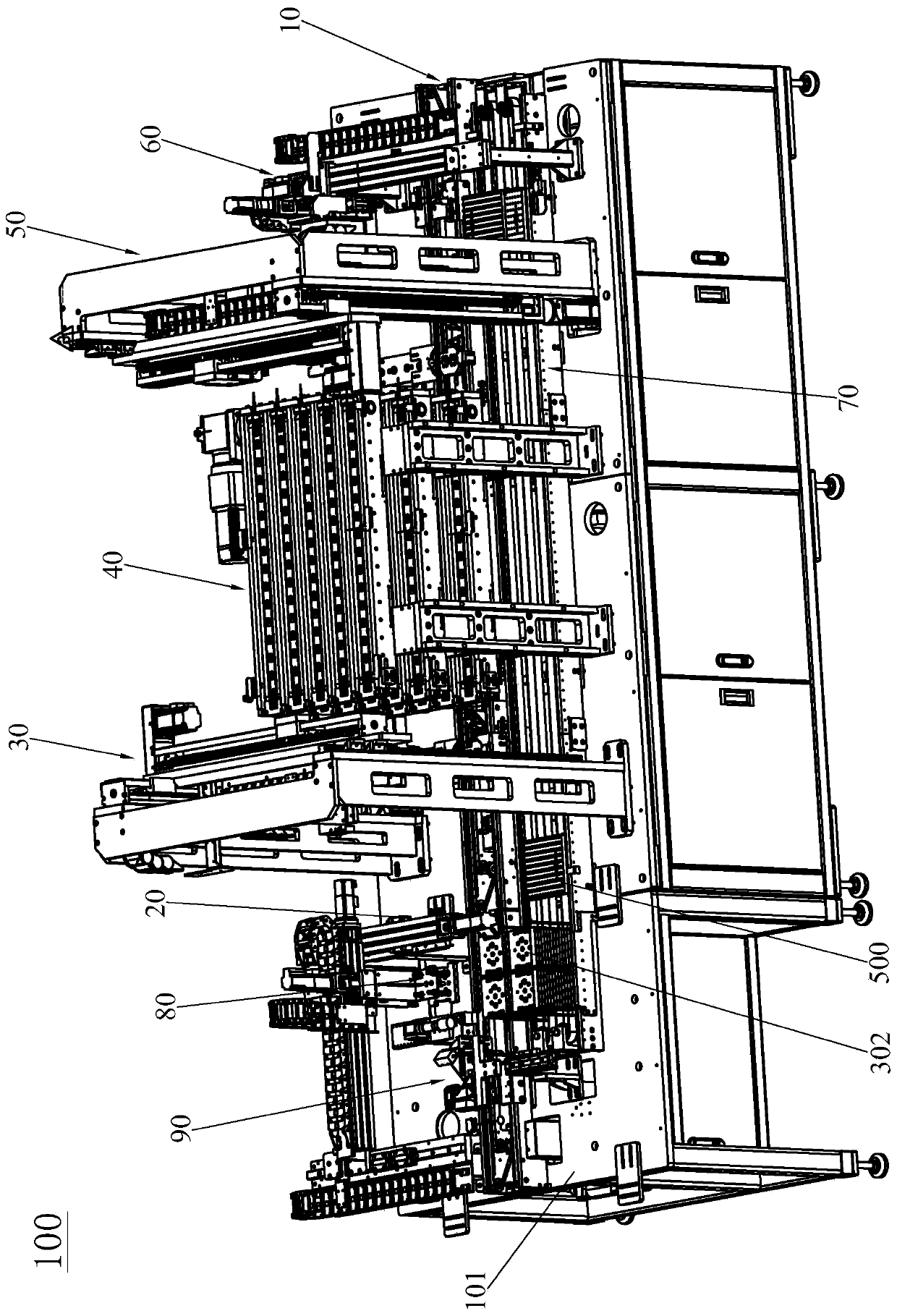

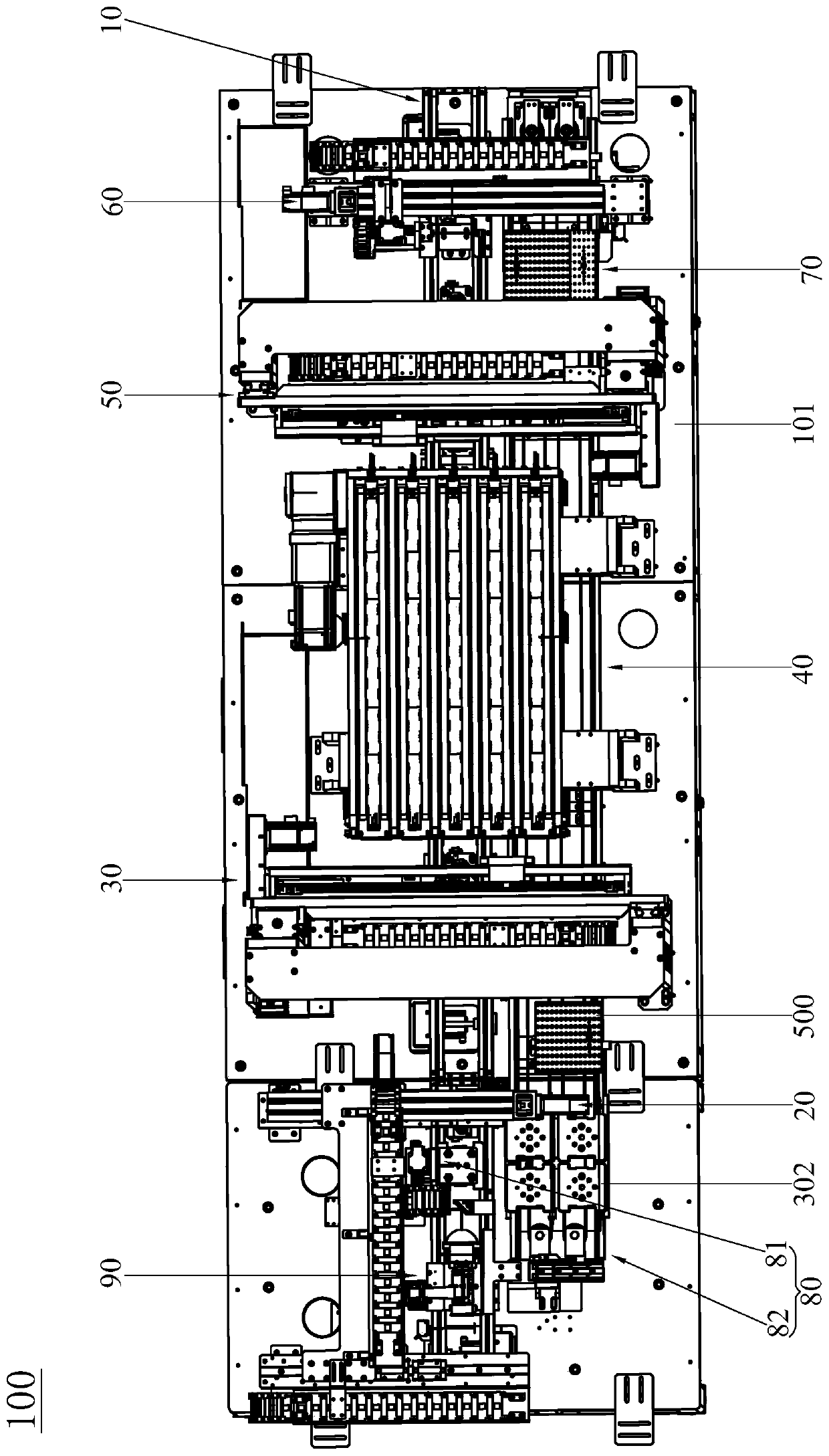

[0025] Refer to Figure 1 to Figure 3 The present invention relates to a product 200 assembled by glue, especially an electronic product. In this application, the product 200 includes, but is not limited to, stylus and stylus components used in electronic products such as mobile phones, tablets, and electronic dictionaries. After the alignment and assembly, the glue is used for fixing, so it is necessary to wait for the glue to solidify to achieve a firm assembly. The present invention discloses a static curing equipment 100, which is suitable for static curing of the glue in the above-mentioned glue-bonded product 200, which includes a conveying device 10 arranged along the longitudinal direction of a working platform 101 and a conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com