Design method for improving aerodynamic elastic stability based on beam structure of ultrahigh-speed aircraft

A technology of aeroelasticity and design method, applied in the direction of design optimization/simulation, sustainable transportation, etc., can solve the problems of structural damage, prone to flutter, insufficient flutter boundary, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiment 1: A design method for enhancing the aeroelastic stability of an ultra-high-speed lower beam structure described in this embodiment, the method includes the following steps:

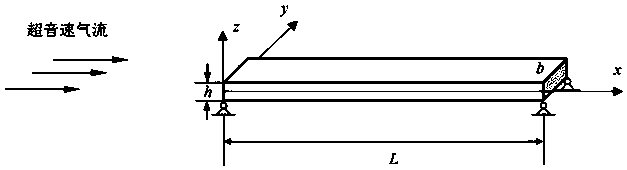

[0020] Step 1. According to the actual use requirements of the beam structure in ultra-high-speed flight, design the basic dimensions of the beam structure; the basic dimensions include the length L, width b, and thickness h of the beam structure, (such as figure 1 shown), and determine the material properties and material parameters at the same time, the material properties are steel (steel is the most commonly used material in aircraft), and the material parameters include elastic modulus E 0 and density ρ 0 ; First determine the corresponding parameters, when E 0 =210GPa, ρ 0 =7860kg / m 3 (This is the inherent property of steel), the beam structure at this time can be called a uniform beam structure (a beam using only steel materials);

[0021] Step 2. After determining t...

specific Embodiment approach 2

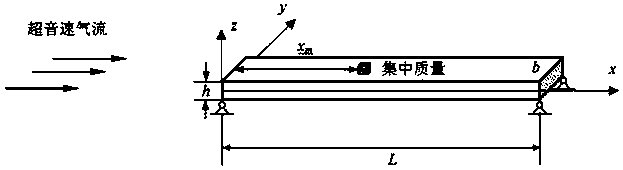

[0023] Embodiment 2: On the basis of a uniform beam structure, the aeroelastic stability of the structure is improved by using an additional lumped mass method; the difference between this embodiment and Embodiment 1 is that in the third step, the additional lumped mass method is used Improve the aeroelastic stability of the beam structure; the specific process is:

[0024] Attach lumped masses to beams, such as figure 2 As shown, by changing the mass m of the concentrated mass c and the position x on the beam m To observe the change of its vibration boundary, obtain the influence law of the lumped mass on the flutter behavior of the structure and determine the optimal m c and x m ;Design with additional lumped mass;

[0025] In the MATLAB program, by continuously changing the mass m of the concentrated mass c and the position x of the lumped mass on the beam m From the simulation results, observe the changes in the flutter order and the flutter boundary, and find the m...

specific Embodiment approach 3

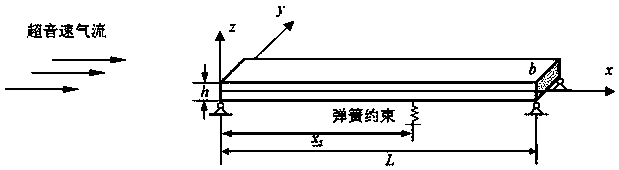

[0027] Embodiment 3: On the basis of a uniform beam structure, the method of spring restraint is used to improve the aeroelastic stability of the structure; the difference between this embodiment and Embodiment 1 or 2 is that in step 3, the spring restraint method is used to improve the aeroelastic stability of the structure. The aeroelastic stability of the structure; the specific process is:

[0028] Such as image 3 As shown, respectively by changing the spring coefficient k c and the spring constraint position x s value, observe the change of its flutter boundary, and determine the optimal elastic coefficient k c and the spring constraint position x s ;The entire beam is divided into two self-spans for design using spring constraints:

[0029] By constantly changing the elastic coefficient k in the MATLAB program c and the spring constraint position x s From the simulation results, observe the changes of the flutter order and the flutter boundary, and find the k that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com