Motor active heat dissipation device

A technology of active heat dissipation and motor box, applied in the direction of electromechanical devices, electric components, cooling/ventilation devices, etc., can solve the problems of different heat generation speeds, affecting the normal use or non-use of electronic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

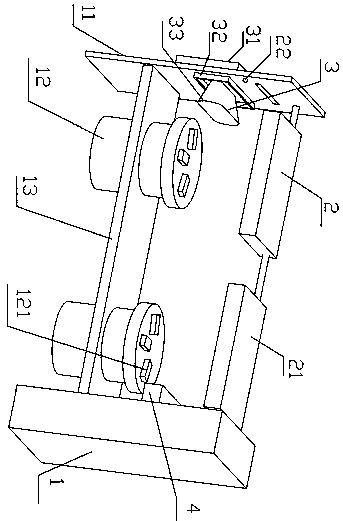

[0027] Example 1, such as figure 1 As shown, an active heat dissipation device for a motor includes a motor box 1, and the motor box 1 includes box walls 11 on all sides. In the figure, for the convenience of demonstration, the other four sides are hidden. Motors 12 are installed in the motor box 1, and the specific quantity of the motors 12 can be adjusted according to requirements, and there are two in the figure. A heat dissipation medium 121 is provided on the upper surface of the motor 12 to further improve the heat dissipation effect. A cooling connecting plate 13 is connected between the two motors 12, on the one hand, it plays the role of stabilizing the motor, and on the other hand, the cooling connecting plate 13 acts as a cooling medium, which has a certain cooling effect on the outer surface of the motor 12.

[0028] An air cooling device 2 is installed above the motor 12, which includes a fan body 21. The quantity of the fan body 21 can also be set by itself acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com