Board surface cleaning equipment for printed circuit board

A technology for printed circuit boards and cleaning equipment, which is applied in the secondary treatment of printed circuits, cleaning methods using liquids, cleaning/polishing of conductive patterns, etc., which can solve the problem of broken circuits on circuit boards, difficult cleaning, and clean board surfaces Unclean and other problems to achieve the effect of avoiding oxidation and cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

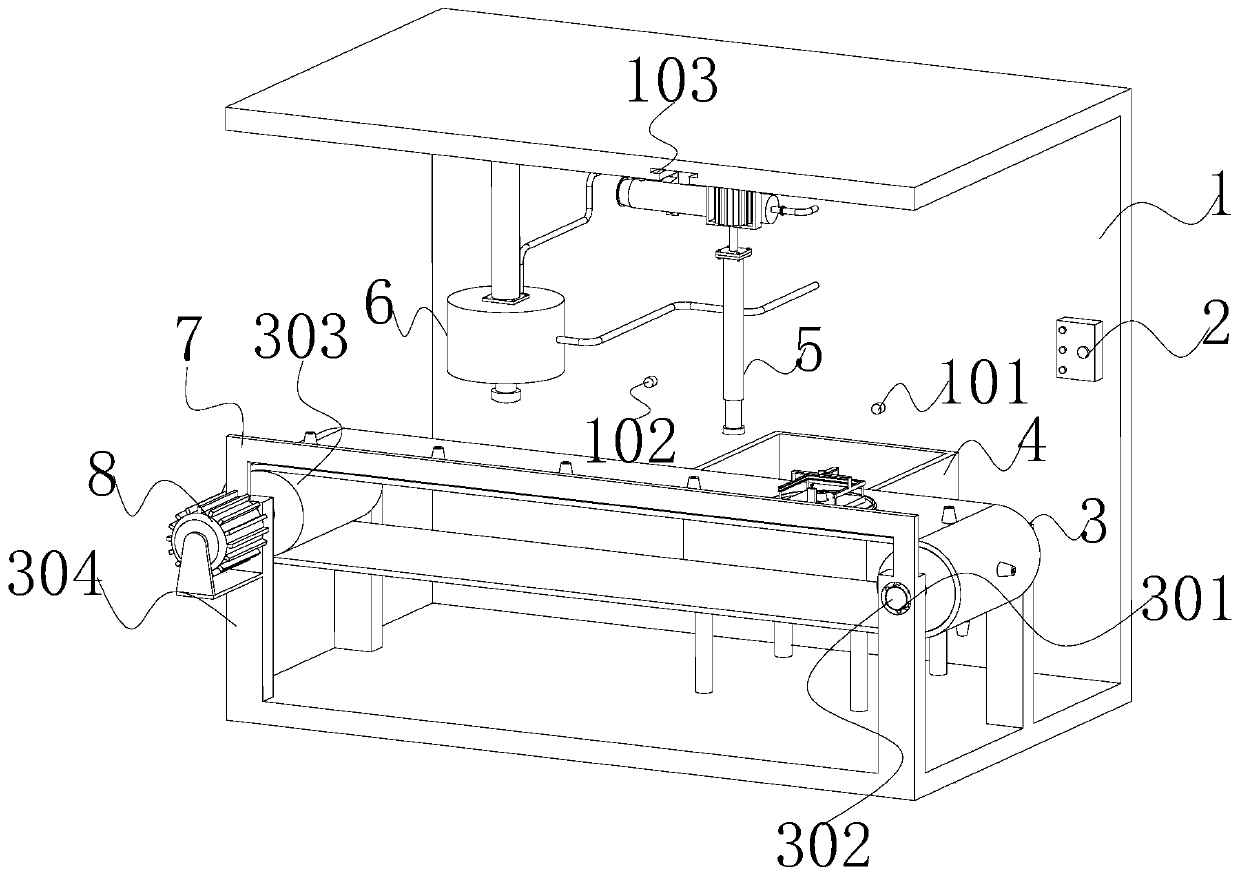

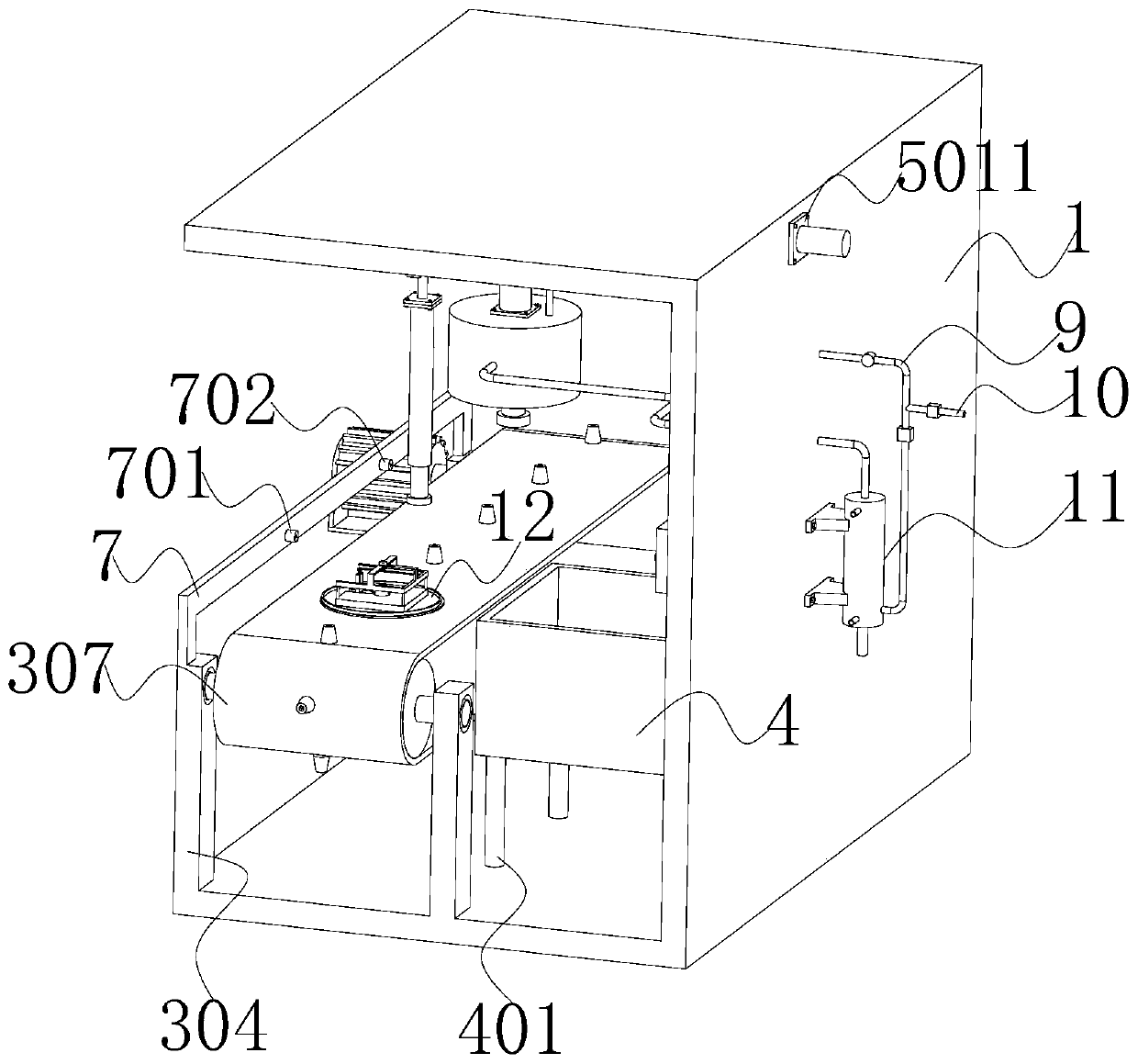

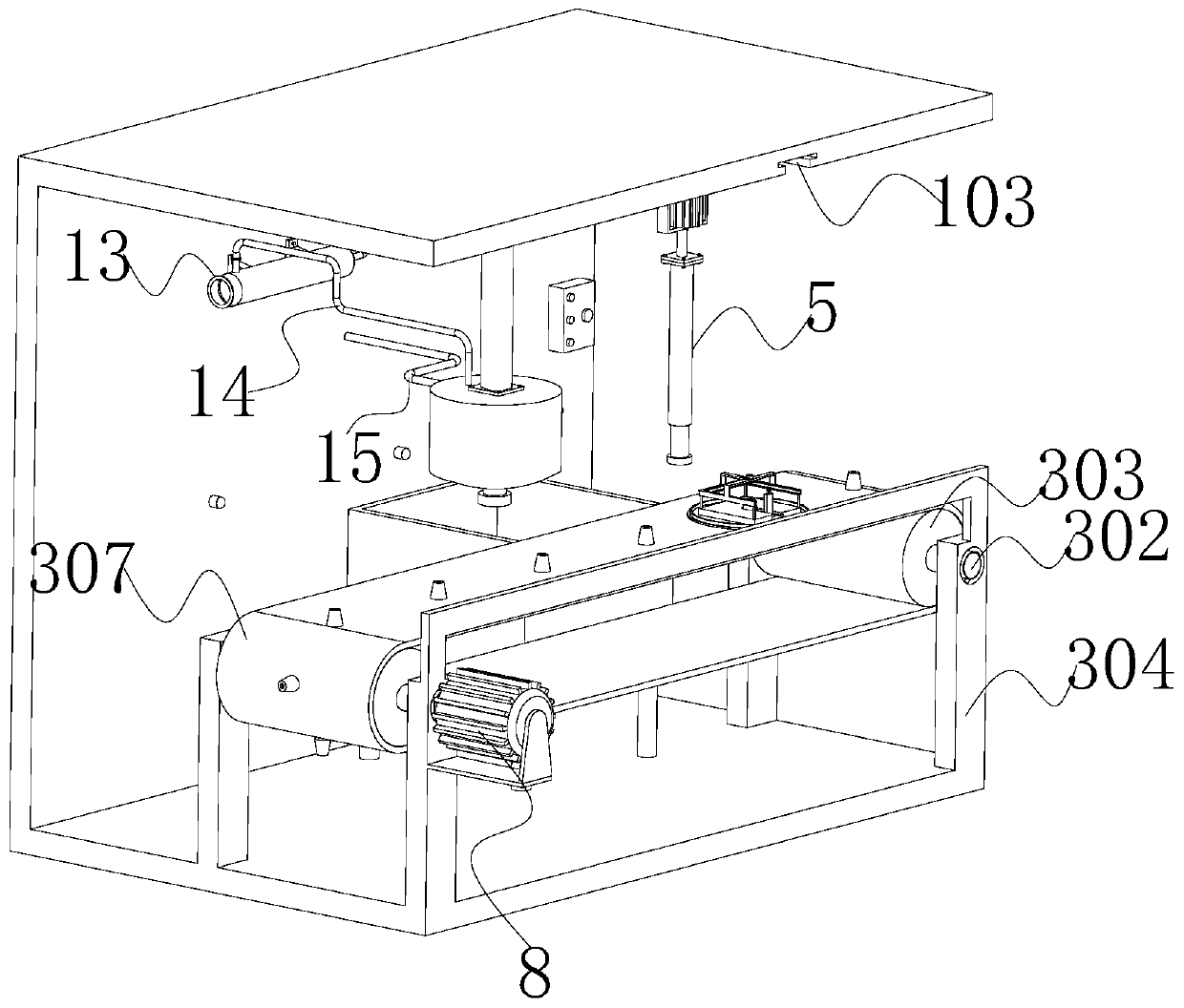

[0052] see Figure 1-3 As shown in and 9, the present invention is a board surface cleaning device for a printed circuit board, comprising a mounting frame 1, a conveying mechanism 3, a cleaning mechanism 5, a drying mechanism 6, a cooling recovery mechanism 11, a fixing mechanism 12 and a heating mechanism 13, The above structure constitutes the basic framework of Embodiment 1;

[0053] The inner lower end position of the installation frame 1 is provided with a conveying mechanism 3, the setting of the conveying mechanism 3 can play a role in conveying the circuit board, and realizes mechanized cleaning. A cleaning mechanism 5 is arranged on one side of the conveying mechanism 3, and the cleaning mechanism 5 is used. To clean the circuit board, a drying mechanism 6 is provided above the other side of the conveying mechanism 3, and the drying mechanism 6 is set for rapid drying of the circuit board after cleaning;

[0054] Wherein, one side of the cleaning mechanism 5 is prov...

Embodiment 2

[0079] Based on the cleaning equipment described in Embodiment 1, an inert gas source is connected to the other end of the fourth delivery pipe 10 for replenishment of the inert gas. The heating of the inert gas can avoid the oxidation of the circuit board by oxygen, and the coolant inlet pipe 1102 and The other end of the cooling liquid outlet pipe 1101 is respectively connected to the inlet and outlet of the cooling liquid source.

[0080] In addition, according to the requirement of production volume, the staff can place several fixing mechanisms 12 with circuit boards fixed on the positioning protrusions 305 one by one, so as to improve the production efficiency.

[0081] The cleaning solution in the cleaning box 4 is selected from volatile liquids, such as alcohol, without damaging the circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com