Silver-coated copper powder with core-shell structure and preparation method and application thereof

A technology of silver-coated copper powder and shell-core structure, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

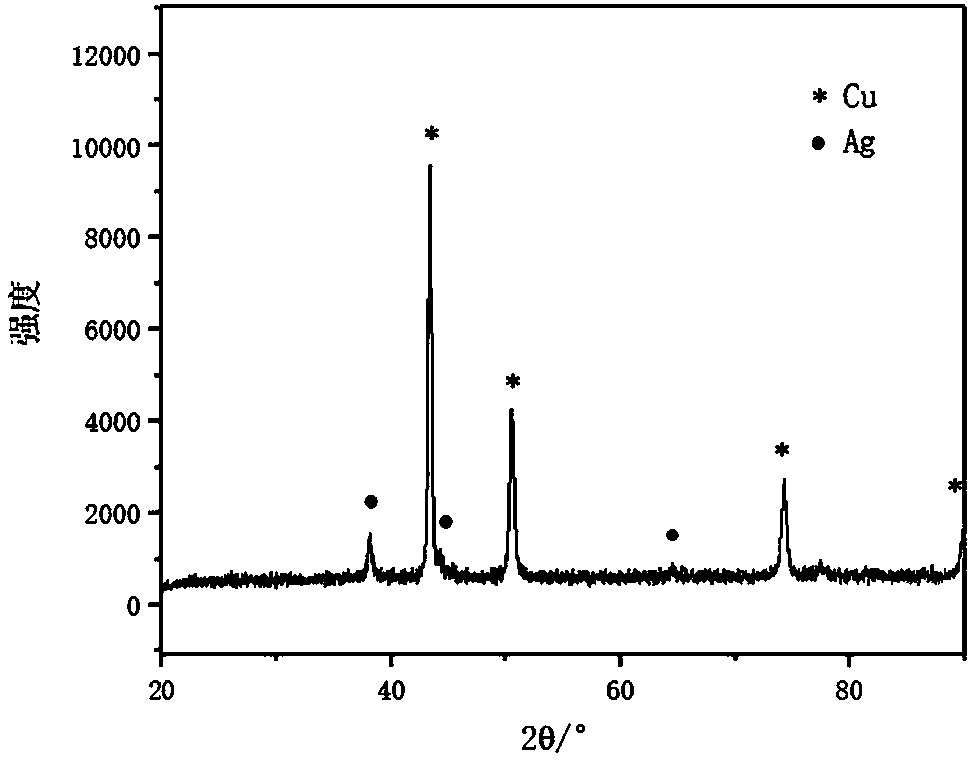

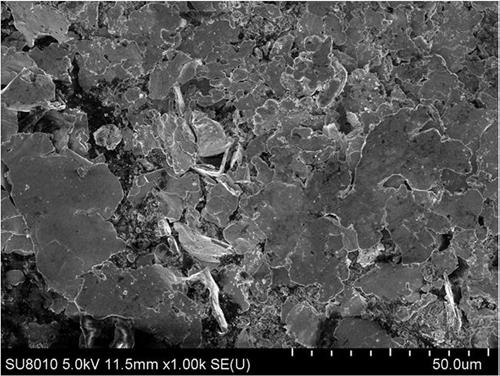

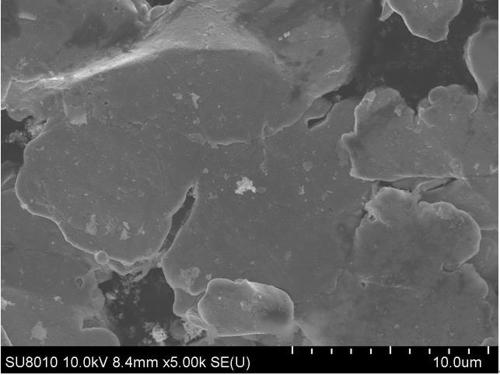

Image

Examples

preparation example Construction

[0042] A preparation method of silver-coated copper powder with shell-core structure, specifically comprising the following steps:

[0043] (1) Disperse the copper powder in the isopropanol solution to prepare a 30-35 g / L copper powder isopropanol mixture, and then add FeCl with 0.3-0.6 times the mass of the copper powder 3 , dispersed evenly to obtain solution A;

[0044] (2) Configure 6-9 g / L SnCl 2 / TiCl 3 hydrochloric acid solution (seed growth agent) in which SnCl 2 / TiCl 3 The mass ratio is 1:1-1:5; then the above solution is dissolved in isopropanol solution to obtain solution B;

[0045] (3) Add solution B to solution A while stirring, and then keep at 40-70 ℃ for 1-2 h;

[0046] (4) Copper powder mass 0.5-1.5% AgNO 3 Dissolve in isopropanol solution to obtain C solution; then add C to (3) while stirring, stir for 1-2 h, then raise the temperature to 40-70 °C for 2-3 h;

[0047] (5) Add 2-10% copper powder mass dispersant to the solution in (4), and keep it at 30-...

Embodiment 1

[0056] (1) Disperse 1 g of flake copper powder in isopropanol at room temperature, and the concentration of copper powder is 33 g / L;

[0057] (2) Add 0.5 g FeCl to (1) 3 , stirring at room temperature for 2-10 min;

[0058] (3) The seed adsorbent SnCl 2 and TiCl 3 Add the mixed hydrochloric acid solution into isopropanol, the ratio of SnCl2 and TiCl3 is 1:3, and the concentration is 8 g / L to configure A solution. Add solution A slowly into (2) and keep stirring. After all the addition, the system is heated to 40-70 ℃ for 1-2 h;

[0059] (4) 0.01g AgNO 3 Add a small amount of isopropanol to configure solution B, and stir to dissolve. Add solution B slowly to (3) with constant stirring. When all the solution B was added, stir at room temperature for 1-2 h. Then, the system was heated to 40-70 °C for 2-3 h;

[0060] (5) Add 0.02 g of dispersant to (4), and heat the system to 30-50 °C for 3 h;

[0061] (6) Add 0.12 g complexing agent to (5) and keep for 1 h;

[0062] (7...

Embodiment 2

[0066] (1) Disperse 1 g of flake copper powder in isopropanol at room temperature, and the concentration of copper powder is 33 g / L;

[0067] (2) Add 0.5 g FeCl to (1) 3 , stirring at room temperature for 2-10 min;

[0068] (3) The seed adsorbent SnCl 2 and TiCl 3 The mixed hydrochloric acid solution was added to isopropanol, the ratio of SnCl2 and TiCl3 was 1:3, and the concentration was 8 g / L to configure A solution. Add solution A slowly into (2) and keep stirring. After all the addition, the system is heated to 40-70 ℃ for 1-2 h;

[0069] (4) 0.01g AgNO 3 Add a small amount of isopropanol to configure solution B, and stir to dissolve. Add solution B slowly to (3) with constant stirring. When all the solution B was added, stir at room temperature for 1-2 h. Then, the system was heated to 40-70 °C for 2-3 h;

[0070] (5) Add 0.02 g of dispersant to (4), and heat the system to 30-50 °C for 3 h;

[0071] (6) Add 0.12 g complexing agent to (5) and keep for 1 h;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com