Preparation method for diamond embedded tool with high holding force

A diamond tool and holding force technology, which is applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problem that formula adjustment is difficult to adapt to stone cutting objects and working conditions, so as to improve cutting efficiency and service life, and achieve high cutting edge , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a high-holding diamond inlaid tool, comprising the following steps:

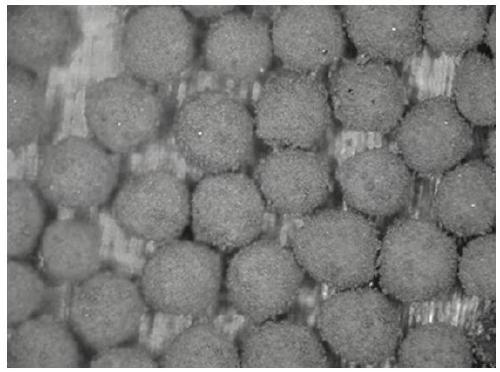

[0028] The first step, diamond wrapping: take brazing powder, metal powder and hard material powder according to the ratio, mix them evenly to make a matrix, and use the method of diamond granulation to wrap the diamond with the mixed powder matrix;

[0029] Preferably, the diamond granulation method is drum granulation or spray granulation, and the powder is wrapped around the diamond. It facilitates the combination of matrix and diamond, and prevents excessive voids during sintering.

[0030] Preferably, the volume ratio of the brazing powder, metal powder and hard material powder is: brazing powder 50-100%, metal powder 0-30%, and hard powder 0-40%. More preferably, the volume ratio of brazing powder, metal powder and hard material powder in the matrix is: brazing powder 50-80%, metal powder 10-30%, hard powder 10-40% . Optimally, the volume ratio of the brazing powder, me...

Embodiment 1

[0040] The preparation steps of a high-grip inlaid diamond wire saw are as follows

[0041] The first step, diamond wrapping: Weigh NiCrP, W powder and WC powder according to the weight ratio of 7:1:2, mix them evenly, adopt the method of drum granulation, and wrap the diamond 1 with the mixed powder;

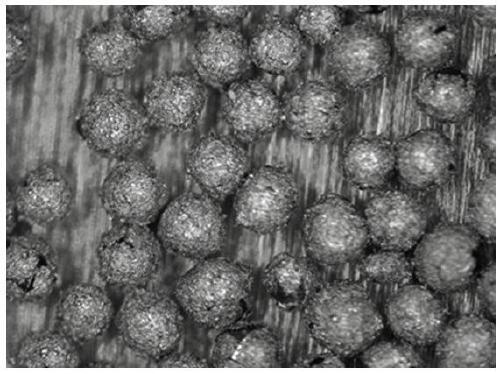

[0042] In the second step, the wrapped diamond 1 obtained in the first step is rapidly pre-sintered at 1000°C with a high-frequency induction vacuum brazing furnace to obtain diamond 2;

[0043] The third step is to granulate the FeCoNiCuSn pre-alloyed powder. After the granulation is completed, mix the granulation with the pre-sintered diamond in the second step in a ratio of 6:4, and then granulate and package for use after mixing evenly; Preferably, the mixing ratio of the granulation in the third step and the pre-sintered diamond can also be adjusted according to the needs of processing, so as to facilitate the control and adjustment of the cost of the diamond tool;

[004...

Embodiment 2

[0048] The preparation steps of a high holding force inlaid diamond tool bit are as follows

[0049] The first step, diamond wrapping: use CuCr30 brazing powder, adopt the method of spray granulation, and wrap the diamond 1 with the mixed powder;

[0050] In the second step, the wrapped diamond 1 obtained in the first step is rapidly pre-sintered at 980°C with a high-frequency induction vacuum brazing furnace to obtain diamond 2;

[0051] In the third step, FeCu30 alloy powder, Cu powder, Sn powder, and carbonyl Ni powder are mixed and granulated in a ratio of 60:15:5:20, and then the granulation is mixed with the pre-sintered diamond in the second step by 6: 4 Mix evenly, granulate again, and package for use;

[0052] In the fourth step, the diamond granulation obtained in the third step is cold-pressed into a diamond cutter head working layer;

[0053] In the fifth step, the working layer of the diamond cutter head obtained in the fourth step is stacked with iron sheets at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com