Automatic corner cutting operation method and device

A working device and corner cutting technology, which is applied in metal processing, sorting, etc., can solve the problems of large impact, difficult memory stick identification, labor-intensive, etc., and achieve the effects of reduced defective rate, high processing efficiency, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment one: a kind of corner cutting automatic operation method, concrete steps are as follows:

[0051]Step 1. Open two adjacent holes on one side of each workpiece, and the distance between the two holes is different for different types of workpieces. The control system registers the positions of the two holes on the workpiece as coded holes that distinguish each workpiece. Open another two adjacent holes on the other side of the workpiece away from the coding hole, and record the distance between the two holes for numbering. When the device drills holes on workpieces, the distance between the two holes on the next workpiece increases by a set distance every time a workpiece passes through in sequence.

[0052] Step 2, storing the distance between two holes on each kind of workpiece.

[0053] Step 3, processing the first workpiece of each kind of workpiece and performing quality inspection.

[0054] Step 4: If the test is qualified, proceed to the next step, an...

Embodiment 2

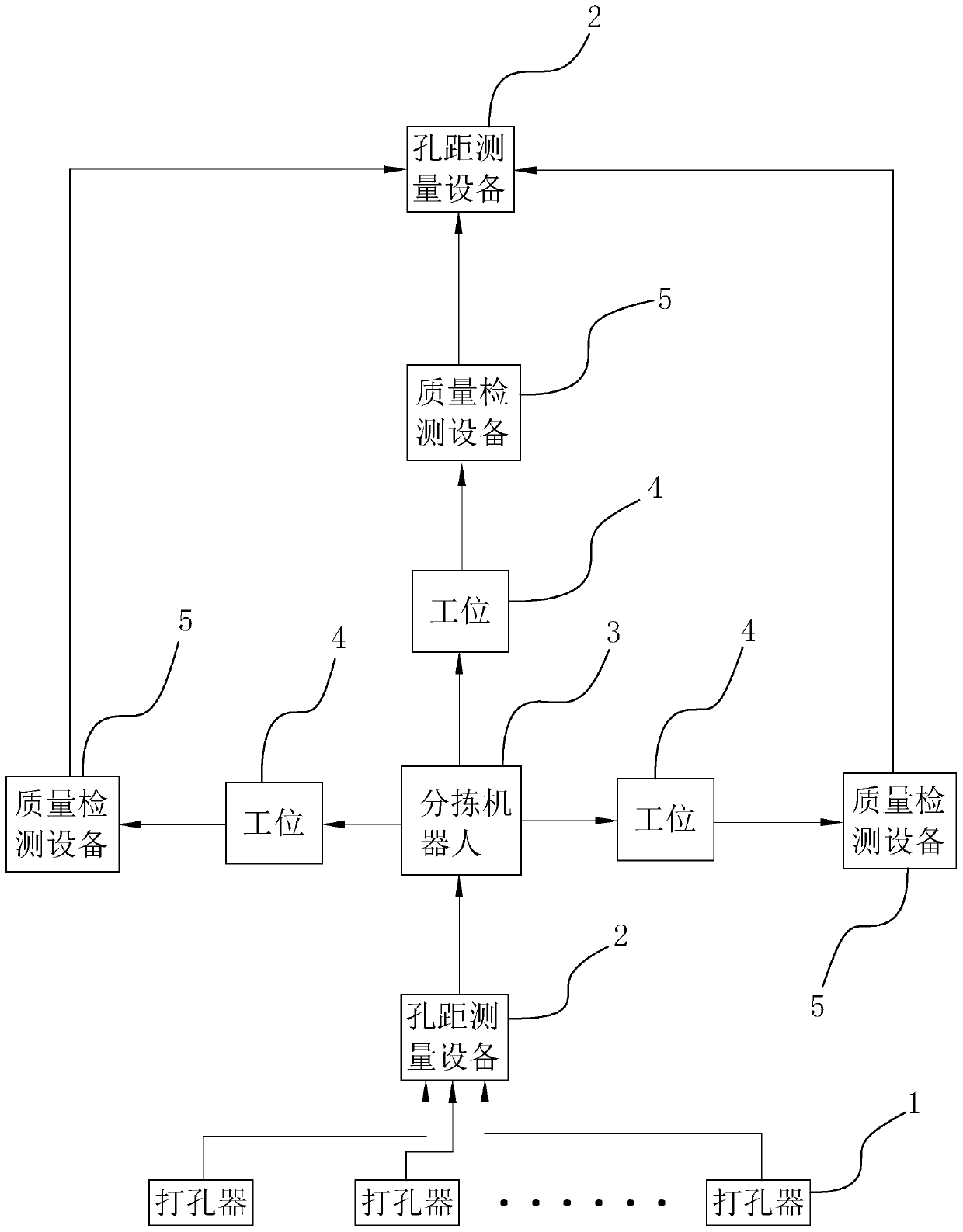

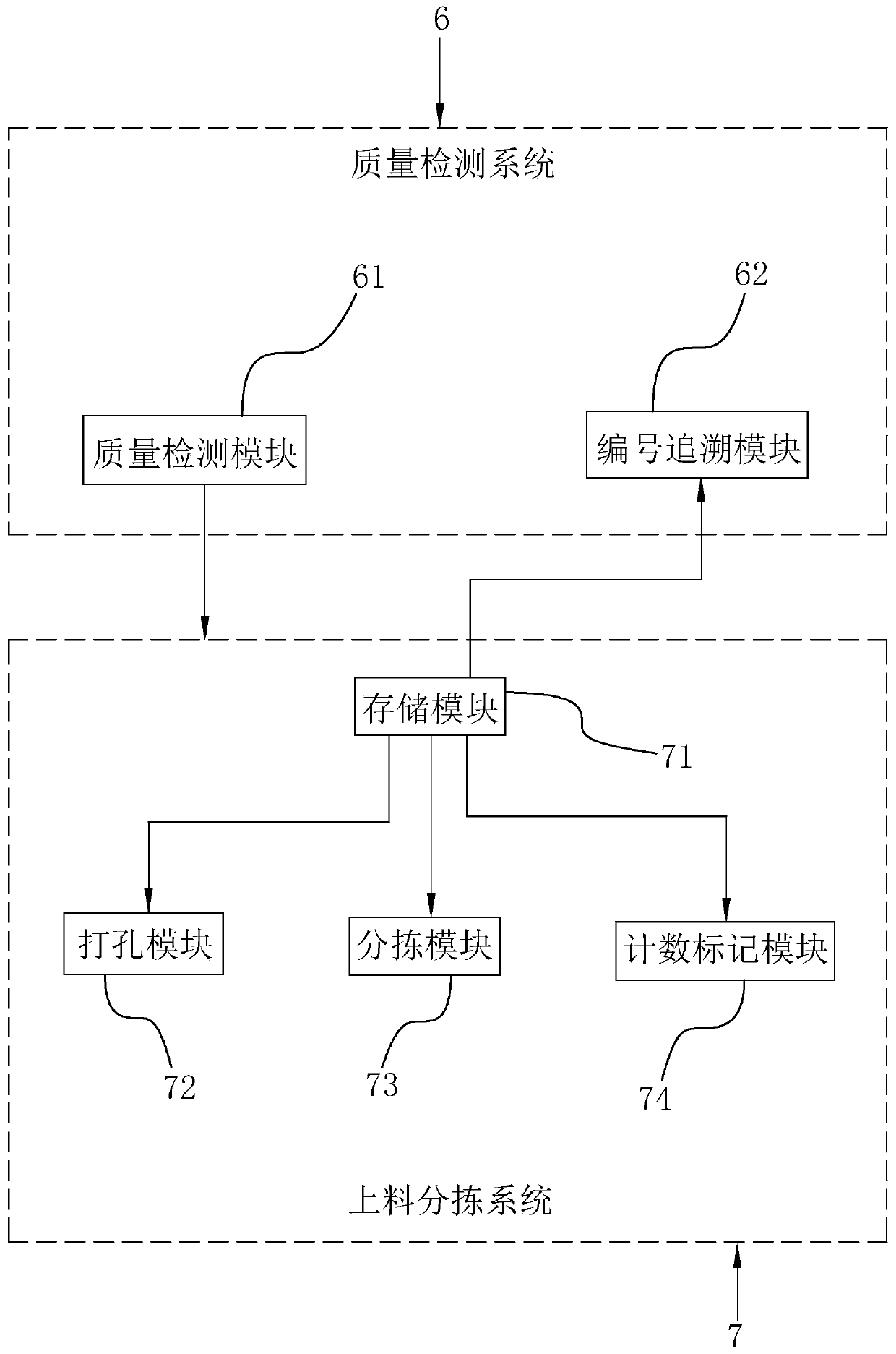

[0062] Embodiment 2, a kind of chamfering automatic operation system, such as figure 1 and figure 2 As shown, it includes several stations 4, puncher 1, sorting robot 3, hole distance measurement equipment 2 and quality inspection equipment 5, hole puncher 1, sorting robot 3, hole distance measurement equipment 2 and quality inspection equipment 5 Connect the control system. The control system includes a feeding sorting system 7 and a quality inspection system.

[0063] Such as figure 1 and figure 2 As shown, the loading and sorting system 7 includes a counting and marking module 74 , a punching module 72 , a storage module 71 and a sorting module 73 . The quality detection module 616 includes a quality detection module 616 and a serial number tracing module 62 . The storage module 71 stores punching distance information and set distances of different types of workpieces, the storage module 71 sends the punching distance information to the corresponding punching module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com