Washing appliance durability testing device based on mechanical arm

A testing device and robotic arm technology, applied in the testing of machines/structural components, measuring devices, manipulators, etc., can solve the problems of neglecting durability testing, product safety burying, time-consuming and labor-intensive, and reduce manual intervention factors. , good ductility, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, so as to make the features of the present invention easier to understand, so as to make a clearer definition of the protection scope of the present invention.

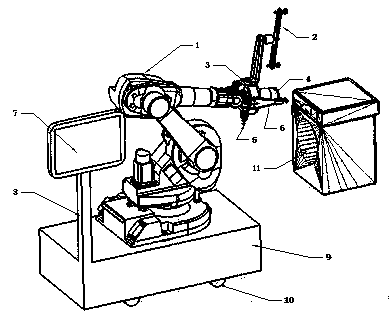

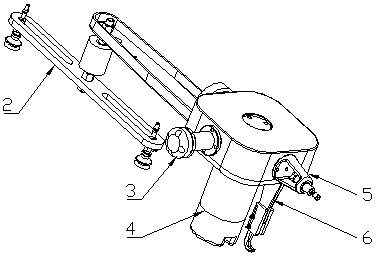

[0020] Such as figure 1 As shown, a washing appliance durability test device based on a mechanical arm includes a six-degree-of-freedom mechanical arm 1, a suction cup mechanism 2, a door pushing mechanism 3, a knob mechanism 4, a finger-like mechanism 5, a hook mechanism 6, a touch screen 7, A connecting arm 8, a support frame 9, a wheeled foot 10, and a sample machine to be tested 11.

[0021] Such as figure 1 As shown, the end of the six-degree-of-freedom mechanical arm 1 is connected with a manipulator composed of a suction cup mechanism 2 , a door pushing mechanism 3 , a knob mechanism 4 , a finger-like mechanism 5 , and a hook mechanism 6 . Among them, the measurement and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com