Ultrahigh-frequency X-ray flaw detector

An X-ray and flaw detector technology, which is used in material analysis, measuring devices, and instruments using wave/particle radiation. The effect of satisfying the conditions of safe use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

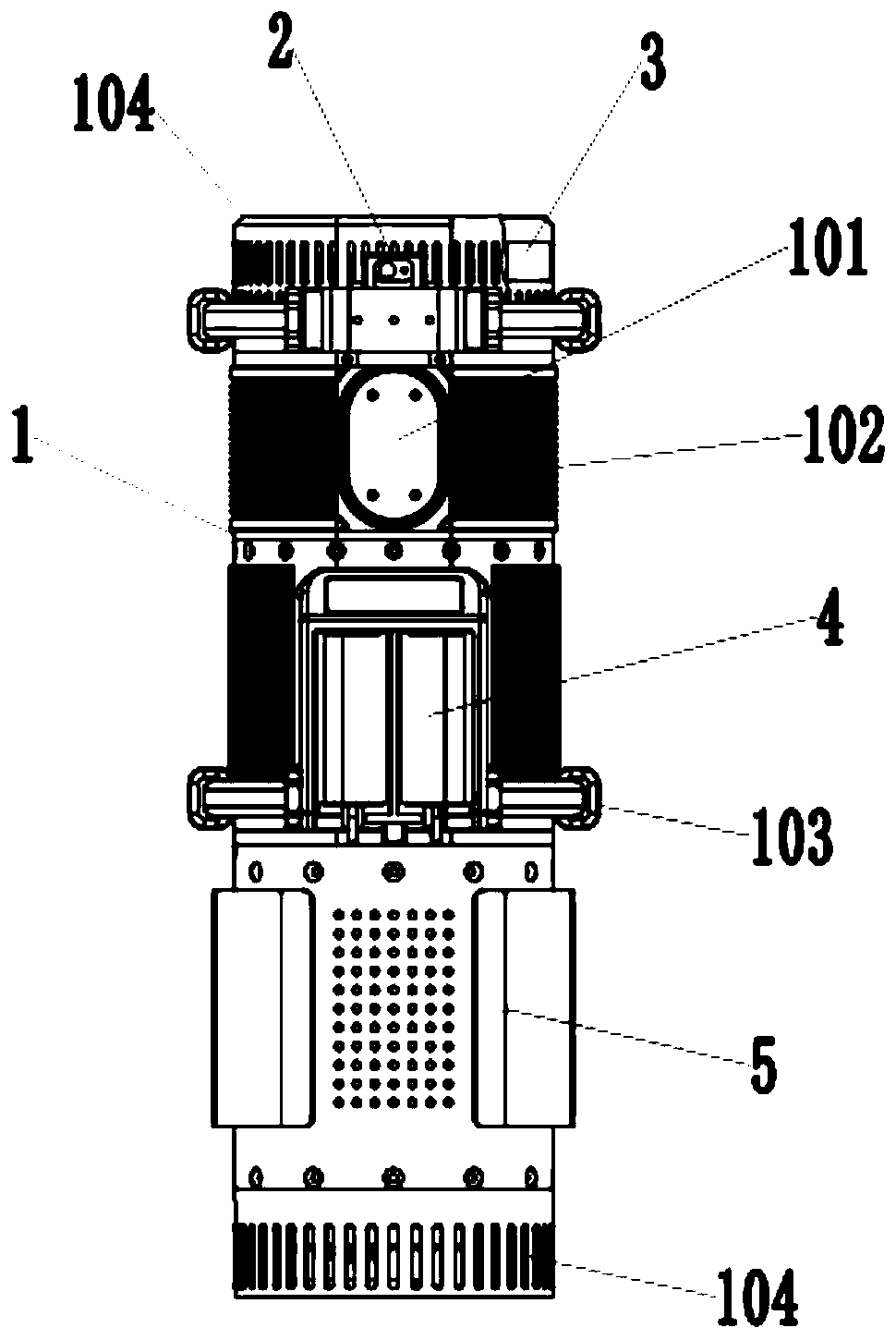

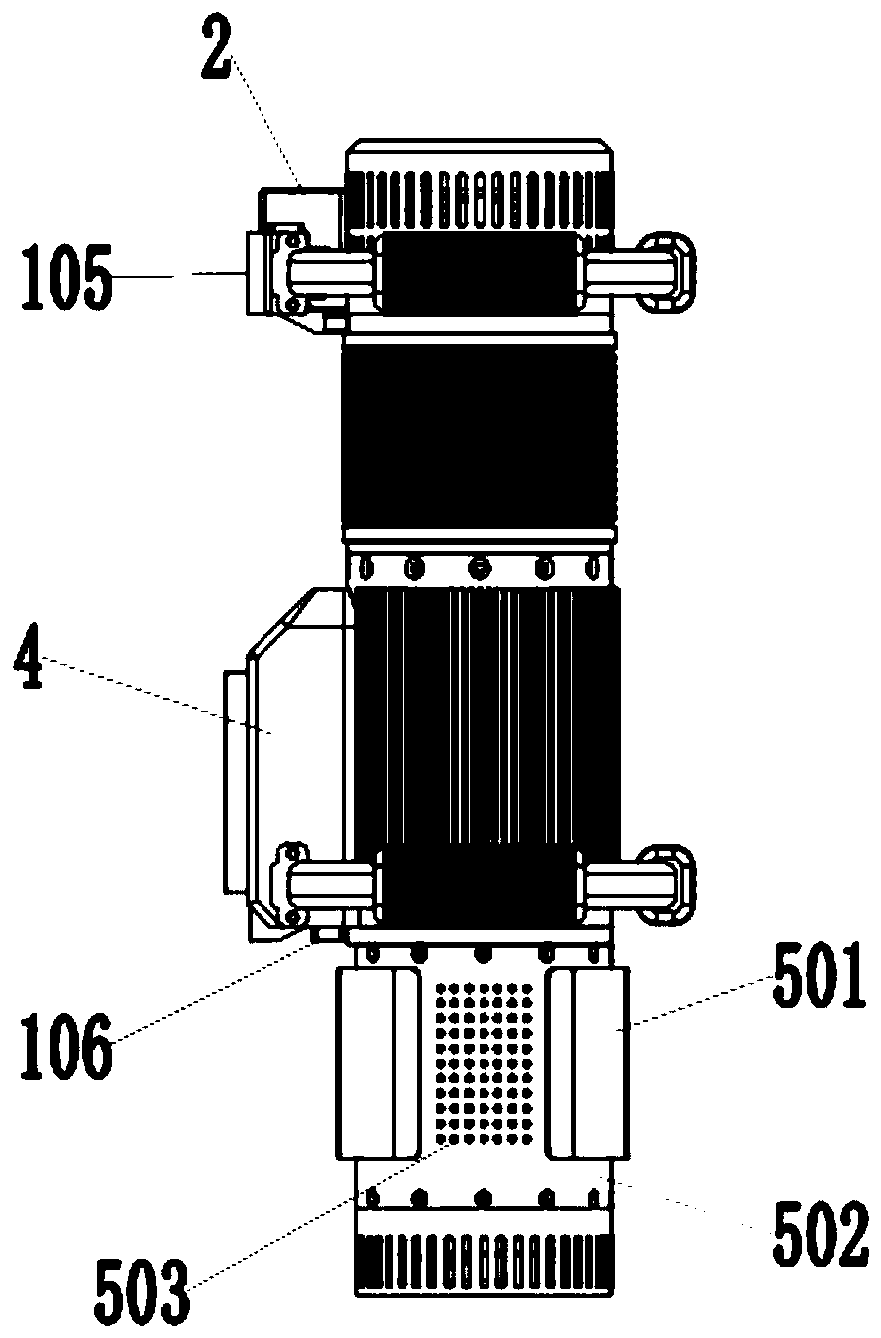

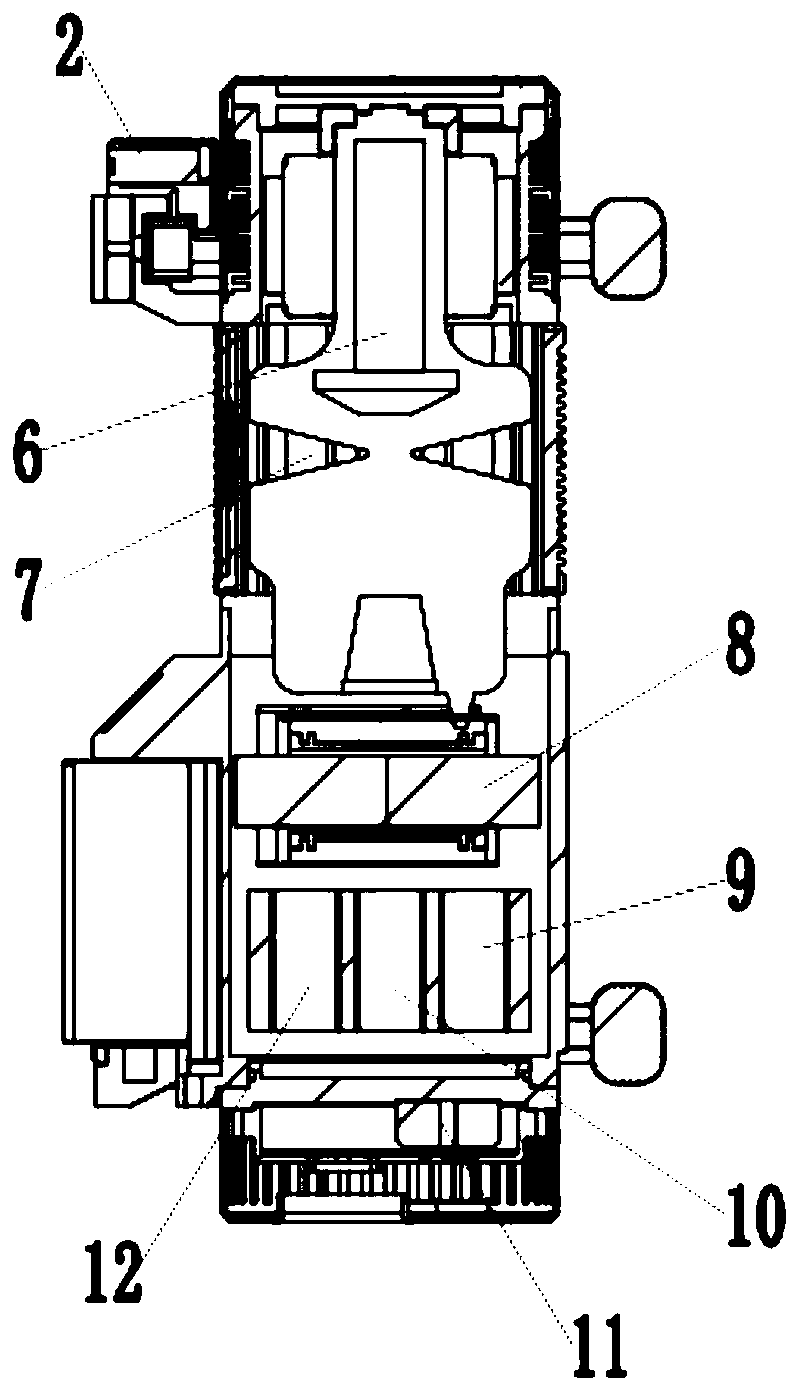

[0037] Such as Figure 1-3As shown, an ultra-high frequency X-ray flaw detection machine and a control system include a casing 1, one end of the casing 1 is provided with a first cooling fan 3, and the first cooling fan 3 adopts a blowing method to dissipate heat, and the other end of the casing 1 A refrigeration device 5 is provided, and the refrigeration device 5 is a detachable mechanism, which is connected with bolts between the casing 1. The outside of the first cooling fan 3 and the end of the refrigeration device 5 are all provided with a cooling wind cover 104, and the two parts of the whole device are connected to each other. beryllium sheet window 101 is provided on the casing 1, and a filter window protection plate is provided on the beryllium sheet window 101, and a beryllium sheet for filtering rays is arranged inside the beryllium sheet window 101, thereby reducing scattering One side of the beryllium sheet window 101 is provided with a laser sensor 2, which is u...

Embodiment 2

[0051] In order to further improve the working efficiency of the equipment, in this embodiment, the ray tube 6 adopts a rotating target ray tube. The rotating target ray tube is fixed and limited in the radial direction by the fixed sleeve, and positioning bolts are set on the casing 1 to limit the axial direction of the rotating target ray tube to ensure the reliability of use. The rotating target ray tube is driven by a rotating motor.

[0052] Compared with Embodiment 1, this embodiment uses a rotating target ray tube, which has a better cooling effect and better work efficiency than a fixed target ray tube, and avoids the fixed working point of the fixed target ray tube, which may be caused by excessive temperature after long-term irradiation. The breakdown problem increases the reliability of equipment use.

[0053] Additionally, if Image 6 As shown, the control system of UHF X-ray flaw detector includes J1900 embedded logic board, 2.4G wireless operation data transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com