Double-power four-wheel-drive five-omnidirectional-wheel heavy-load spherical robot

A spherical robot, omnidirectional wheel technology, applied in the direction of wheels, motor vehicles, transportation and packaging, etc., can solve the problems of poor load-bearing capacity, inaccuracy, laborious movement trajectory, etc., to achieve flexible and rapid movement, increase contact area, easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

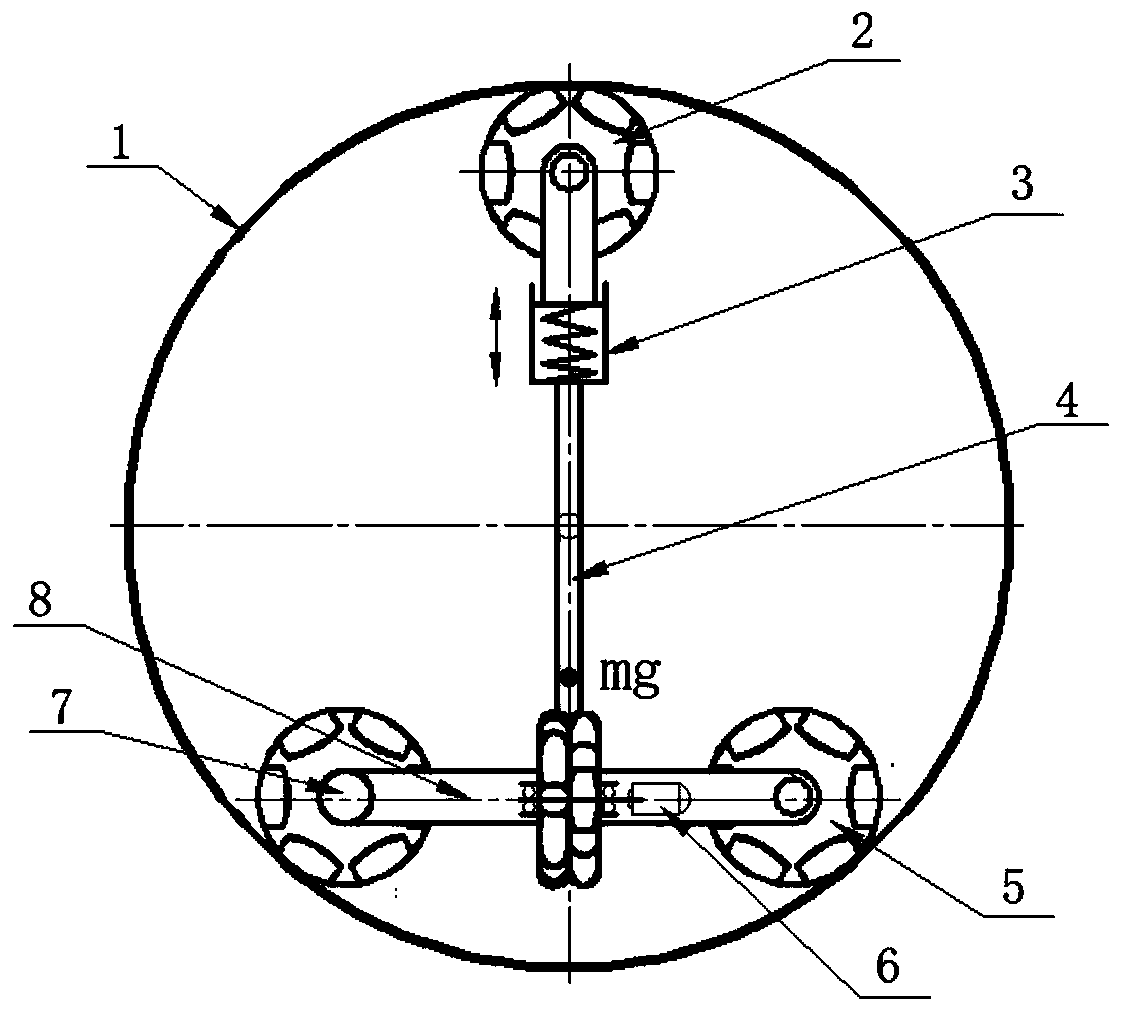

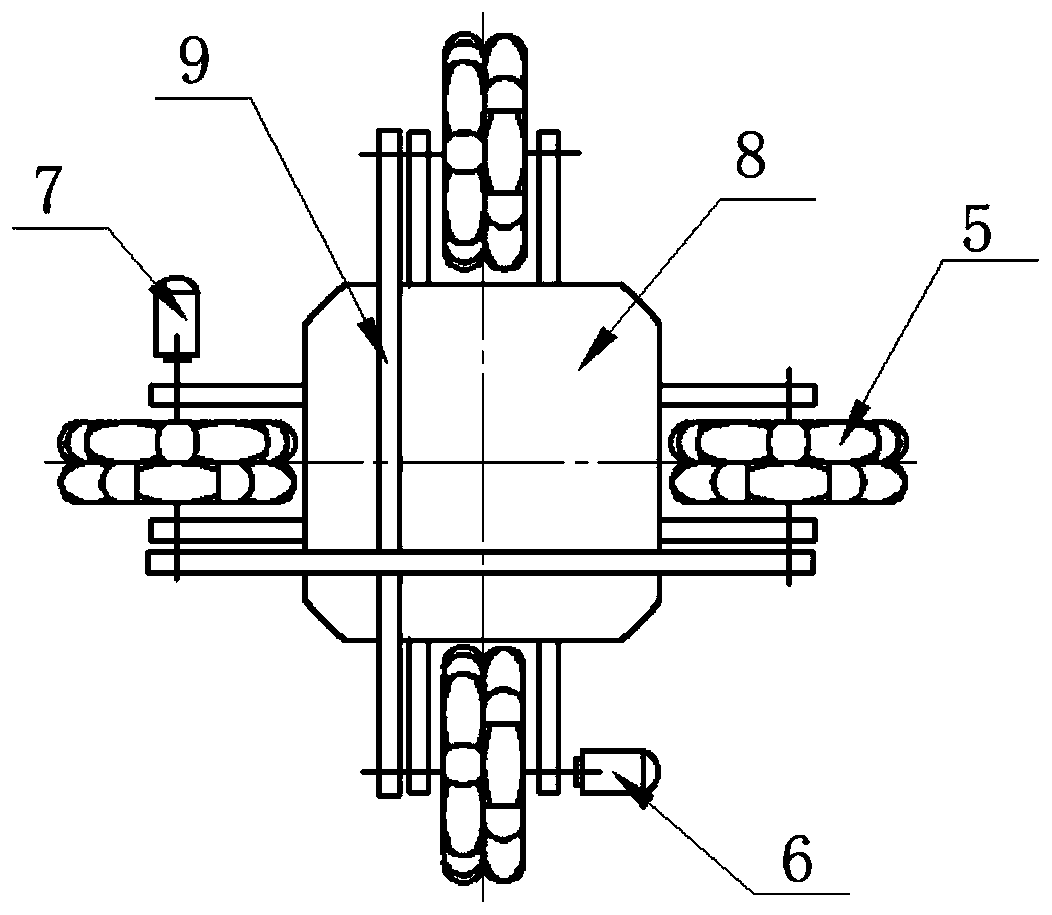

[0046] Example 1: Marching Movement

[0047] like Figure 4 As shown, a group of driving omnidirectional wheels 5 is driven by the driving drive 7 to drive the internal device of the sphere to move along the inner surface of the spherical shell, and the position of the center of gravity mg is shifted, thereby generating an eccentric moment to drive the sphere to roll. At this time, another group of driving The movement of the omnidirectional wheels is not affected, and the steering movement can be performed at the same time.

Embodiment 2

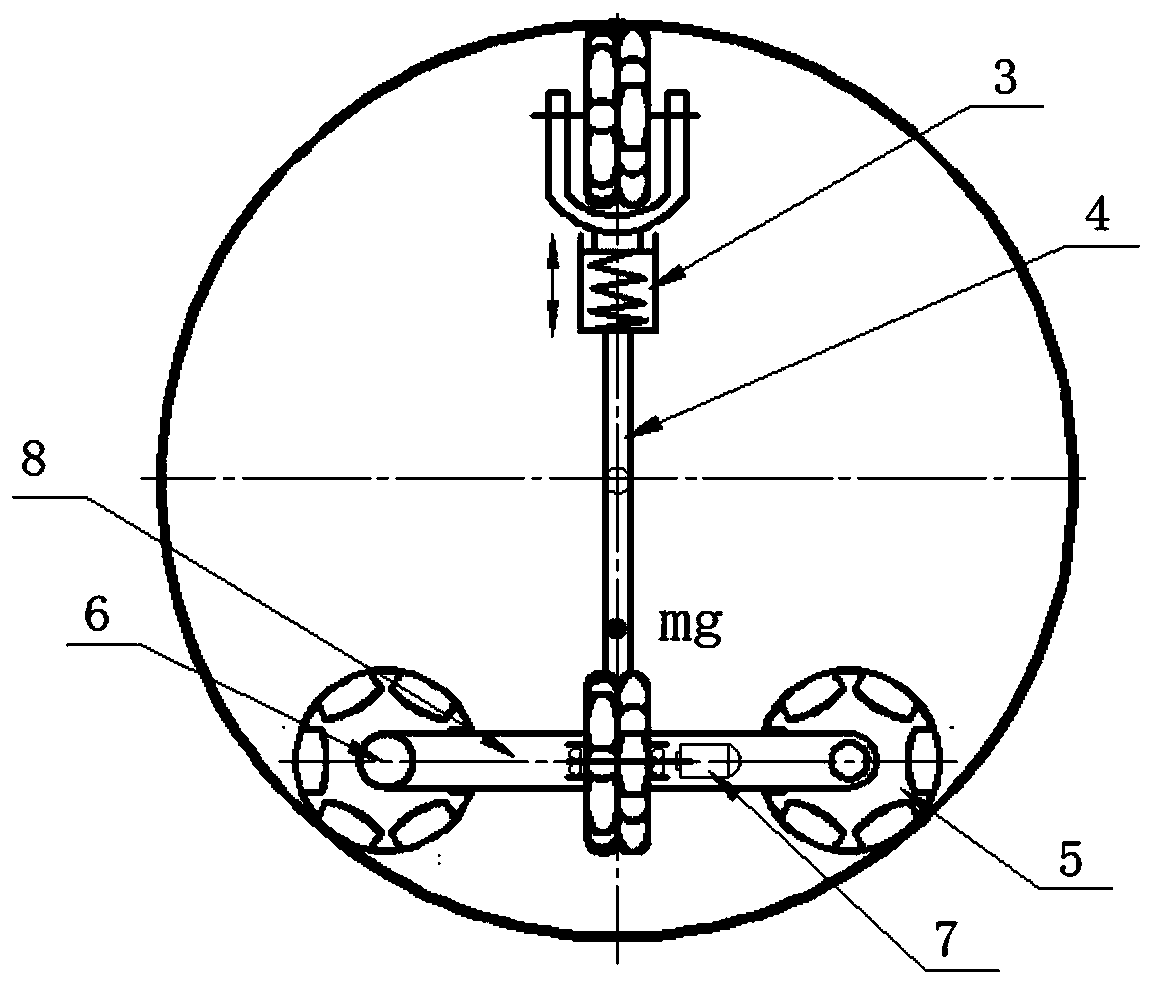

[0048] Example 2: Steering Movement

[0049] like Figure 5 As shown, a set of driving omnidirectional wheels 5 is driven by the steering drive 6 to drive the internal device of the sphere to move along the inner surface of the spherical shell, and the position of the center of gravity mg is shifted, thereby generating an eccentric moment to drive the sphere to roll. At this time, another set of driving The motion of the omnidirectional wheels is unaffected and travel motions can be performed simultaneously.

[0050] As can be seen from the technical solutions provided by the above-mentioned embodiments of the present invention, the present invention has the following advantages:

[0051] The invention significantly increases the contact area between the omnidirectional wheel and the spherical shell, thereby distributing the internal pressure of the spherical shell, so as to be able to carry a larger working load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com