Aluminum liquid online degassing device

A technology of gas device and molten aluminum, applied in the field of on-line degassing device of molten aluminum, can solve the problems of high price and easy damage of graphite rotor, and achieve the effects of no maintenance, cost saving and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

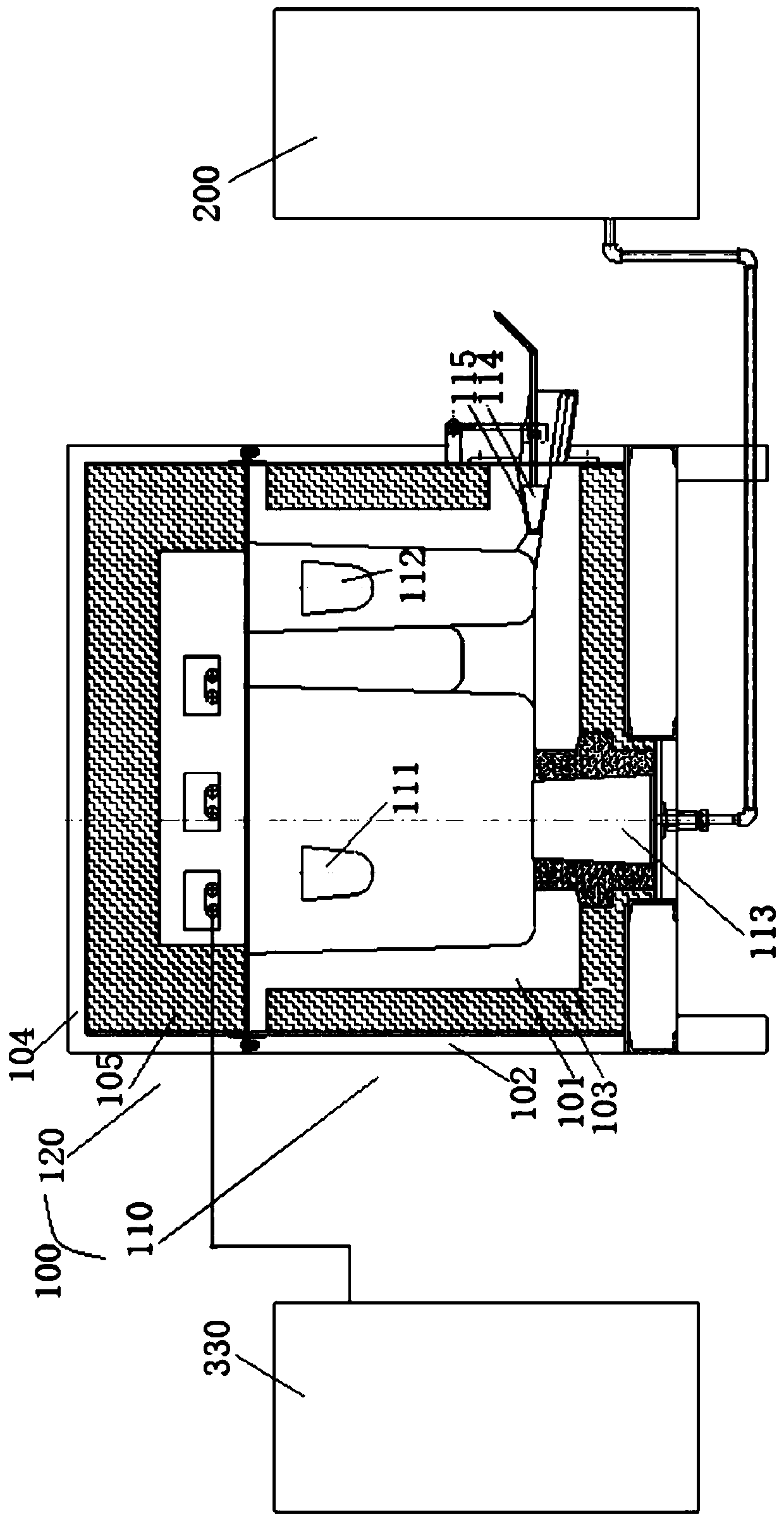

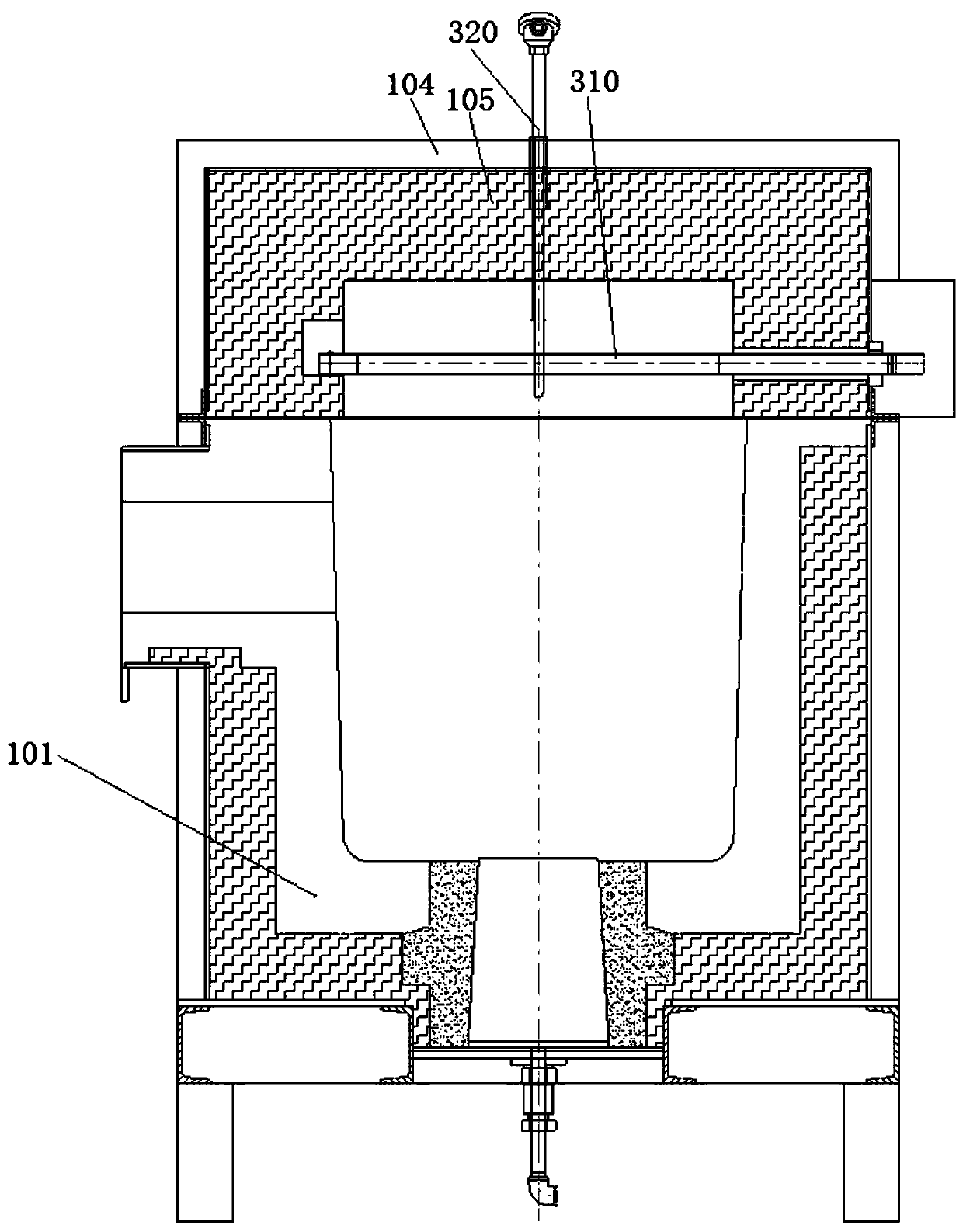

[0021] see figure 1 and figure 2 , as shown in the legend therein, an aluminum liquid online degassing device includes a degassing unit 100 and a gas distribution unit 200, the degassing unit 100 includes a degassing box, and the degassing box is an incubator, which includes a box body 110 and The box cover 120, the box body 110 is provided with the aluminum inlet 111 and the aluminum outlet 112 higher than its internal aluminum liquid level, and the box body 110 is also provided with the air inlet lower than its internal aluminum liquid level, the inlet The gas inlet is provided with a ventilation brick 113, and the gas distribution unit 200 communicates with the gas inlet.

[0022] In a preferred implementation of this embodiment, the aluminum inlet 111 and the aluminum outlet 112 are arranged on the side wall of the box body 110 , and the air inlet is arranged on the bottom wall of the box body 110 .

[0023] In a preferred implementation of this embodiment, the gas dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com