Segment prefabricated and assembled bridge pier stud and construction method thereof

A technology for prefabricating and assembling piers and columns, which is applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of discontinuous concrete pouring, insufficient integrity of piers and columns, affecting seismic performance, etc., and achieves high construction efficiency and seismic performance. And the effect of good force and good force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

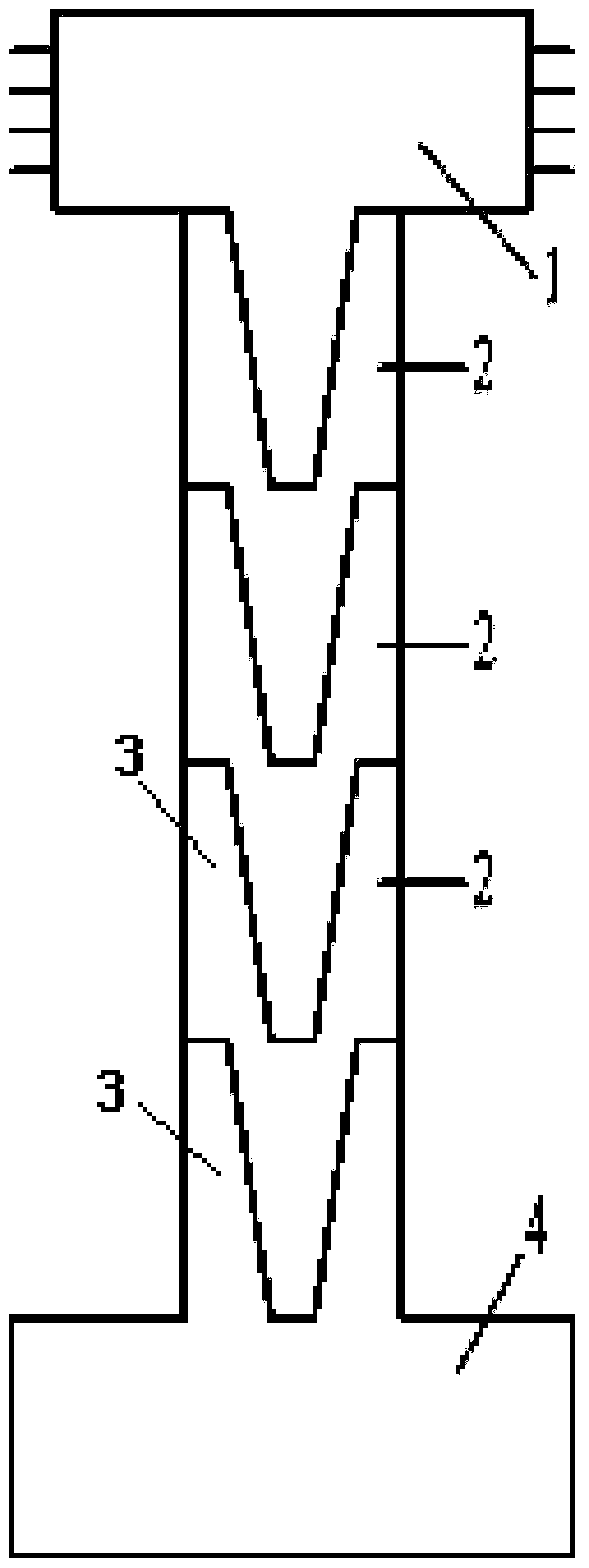

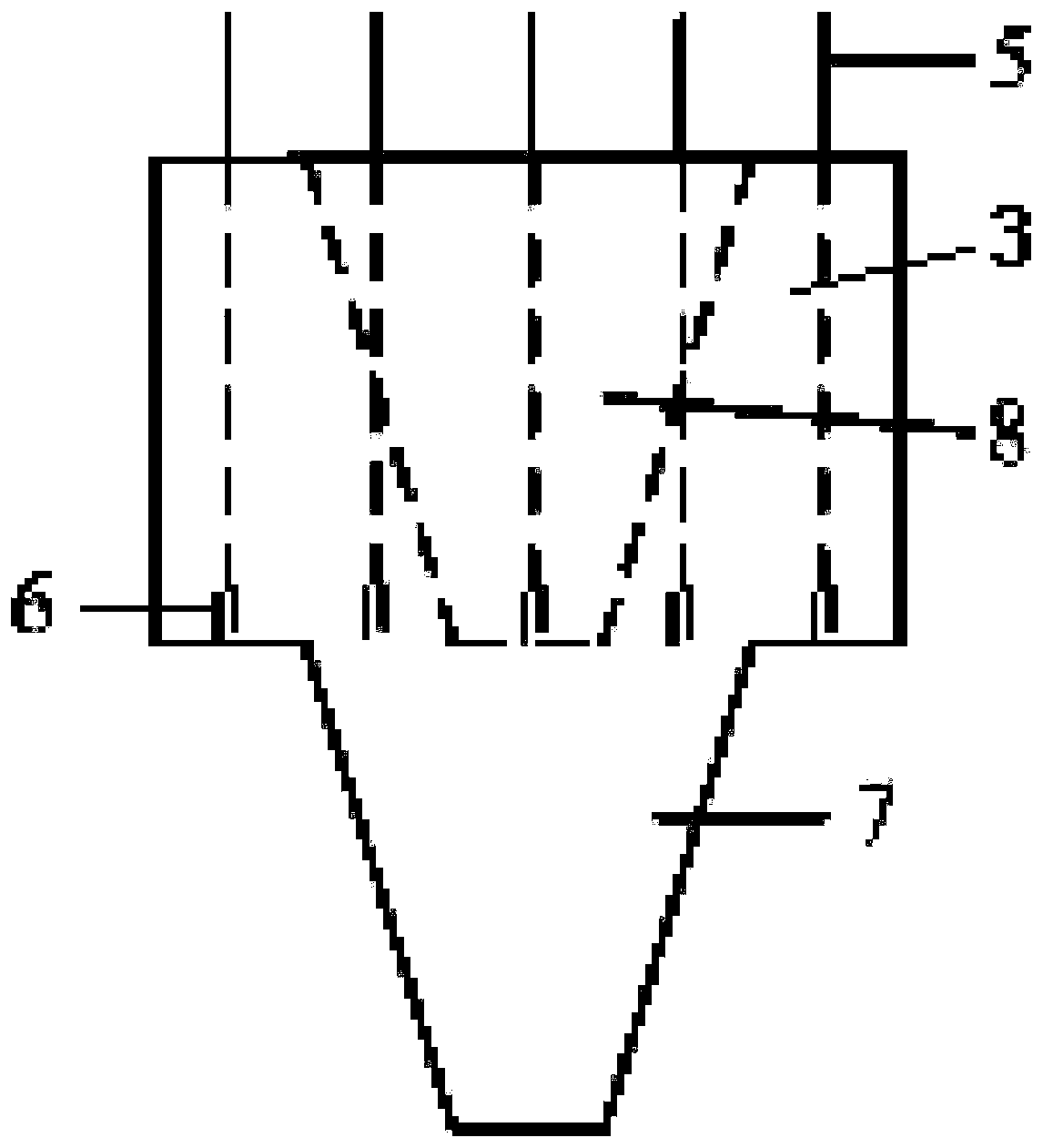

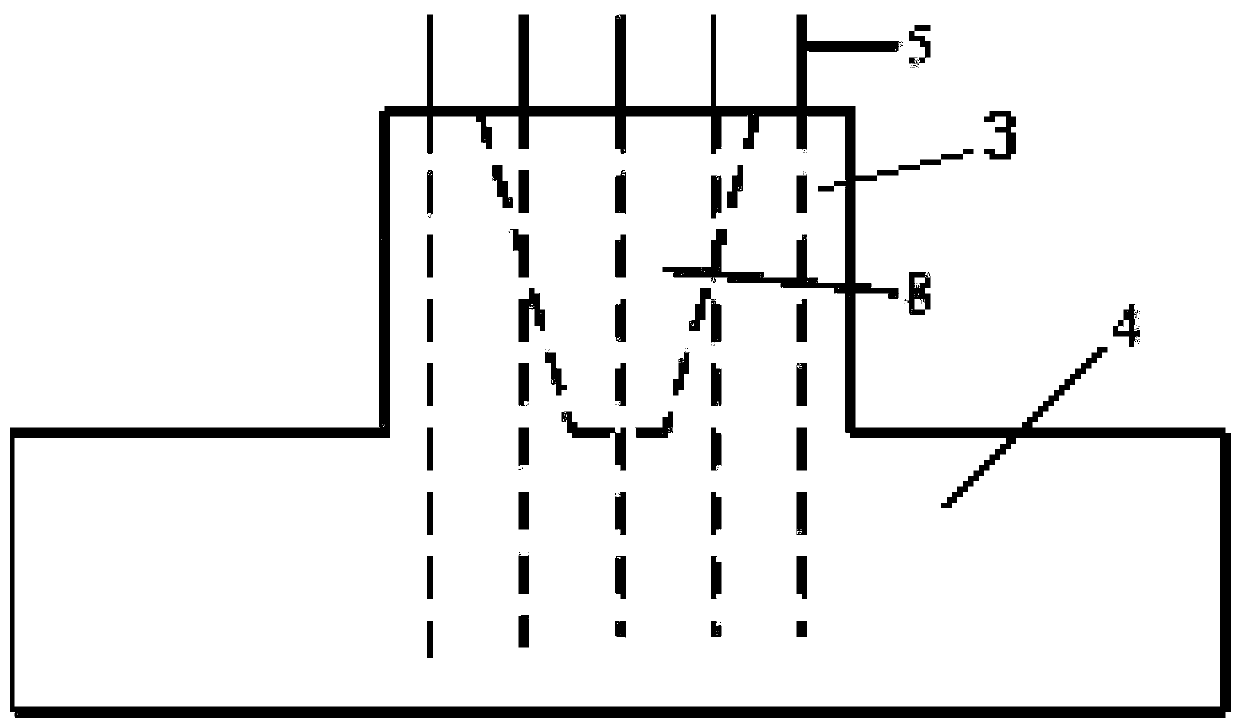

[0034] Embodiment: combine below Figure 1~Figure 7 The specific implementation of a segmental prefabricated and assembled bridge pier column provided by the present invention is described as follows:

[0035] A segmental prefabricated and assembled bridge pier column, which is composed of a cap 4 arranged from bottom to top, a pier column body and a cover beam connecting segment 1, the pier column body is a segmented prefabricated assembly, which consists of several The same pier column segment 2 is spliced; the lower part of the pier column segment 2 is a protruding prism 7, and the upper part is an annular protrusion 3, and the annular protrusion 3 is provided with an auger groove 8. The abutment The shape and size of the groove 8 and the edge platform 7 are mutually nested. The annular protrusion of the pier column segment 2 is pre-embedded with a vertical steel bar 5 and emerges upward. The lower end of the vertical steel bar 5 has a grouting sleeve The pipe 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com