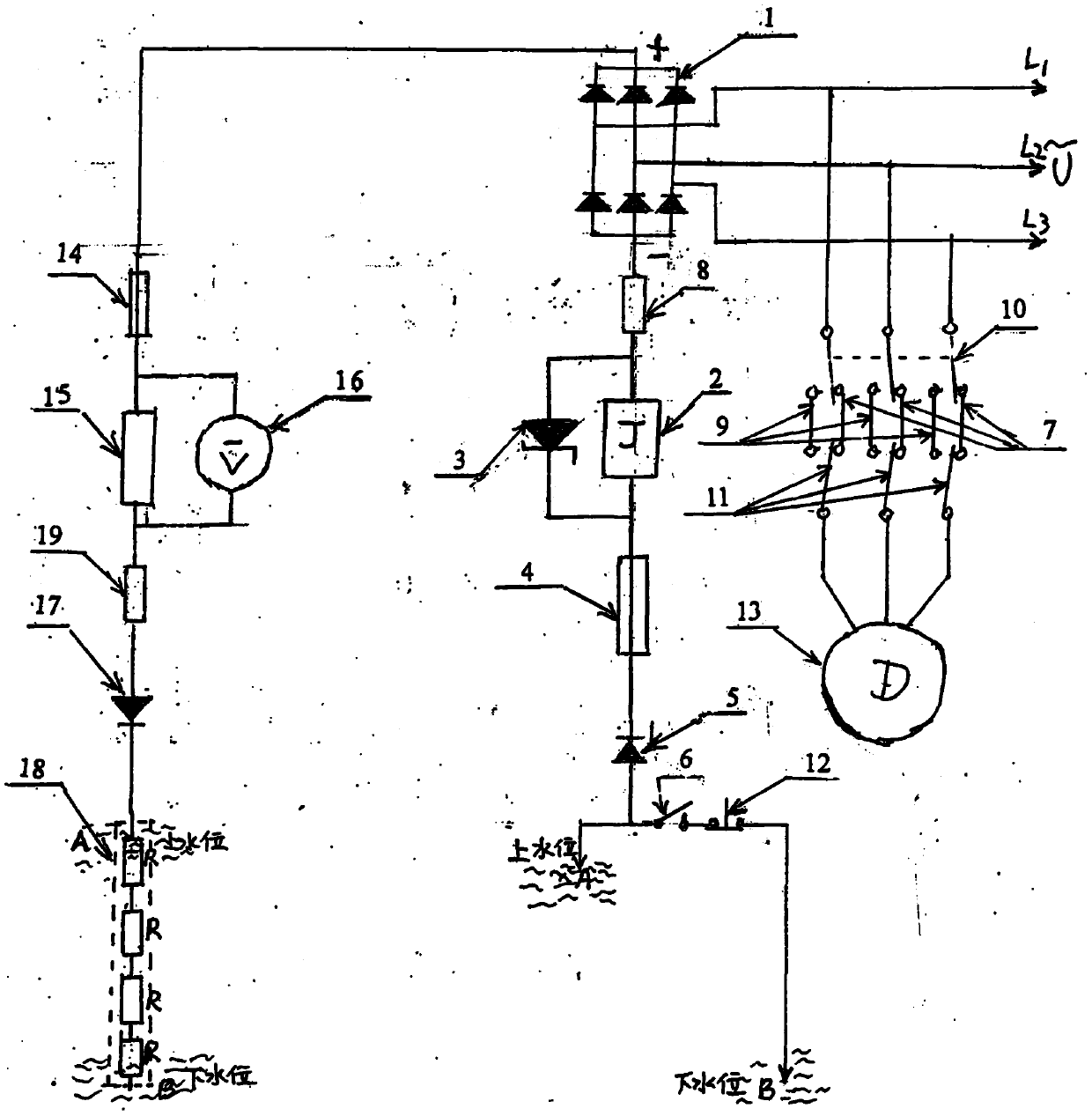

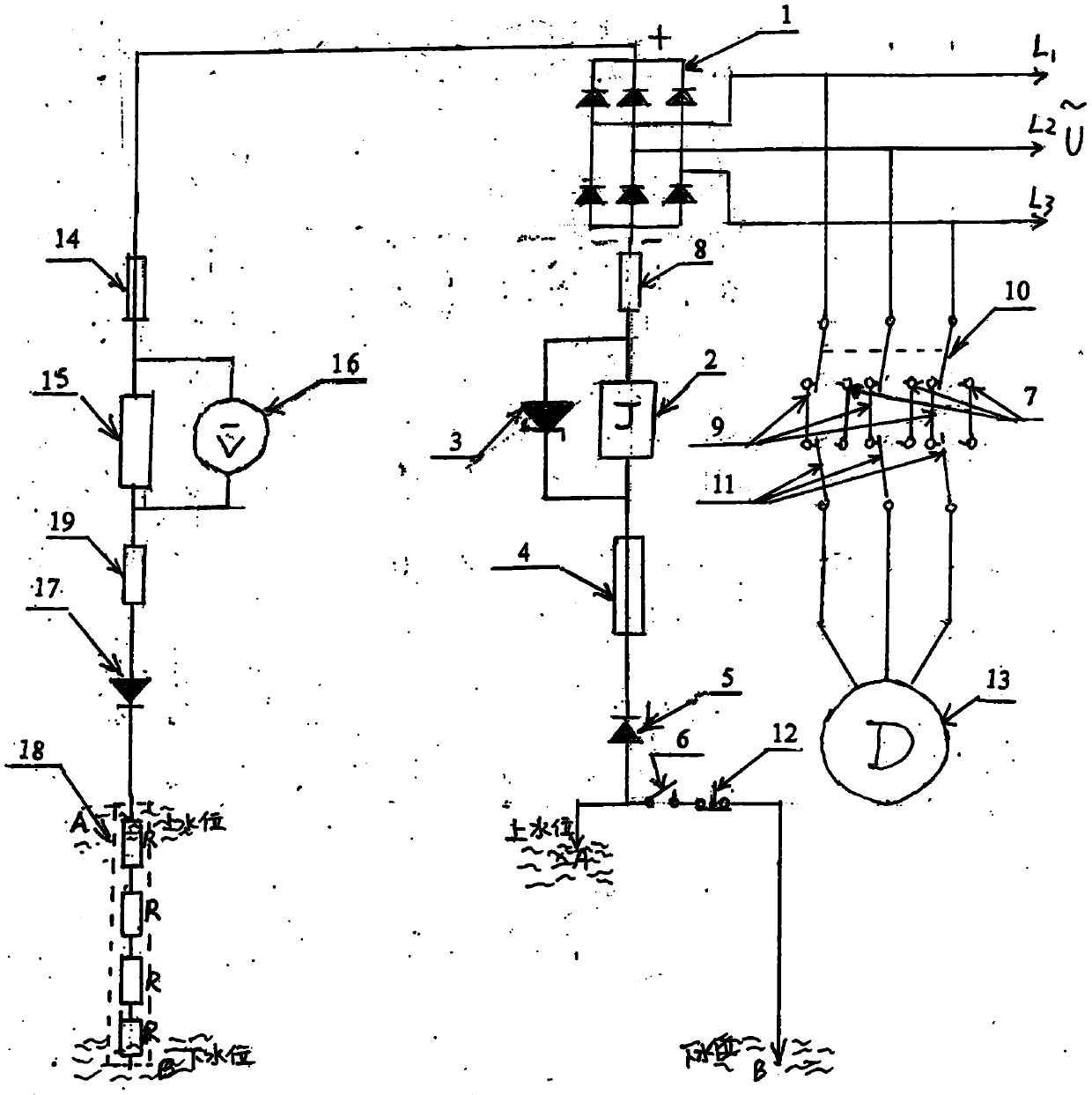

Three-phase water pump water supply and drainage control and voltage-type water level display

A voltage type and display technology, applied in pump control, liquid level indicator for physical variable measurement, machine/engine, etc., can solve the problems of high failure rate, cumbersome line installation, etc., and achieve low line loss and long transmission distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

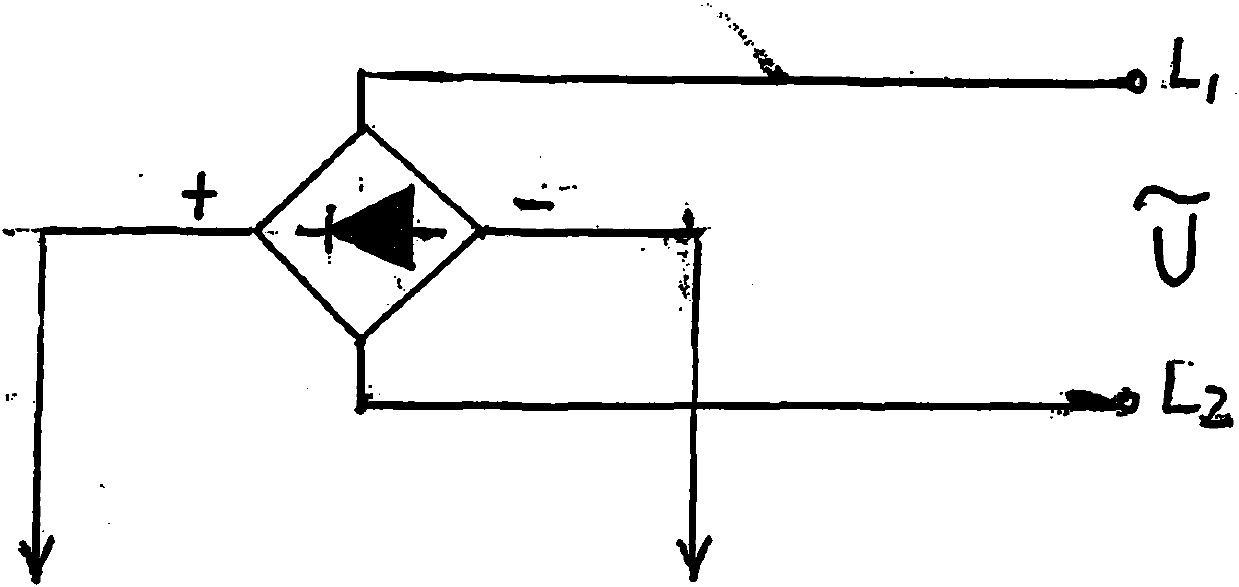

[0032] figure 1 It is a schematic diagram of three-phase water pump supply, drainage control and voltage type water level display water supply. The DC negative pole output by the AC power supply through the three-phase rectifier bridge (1) is sequentially connected in series with a voltage dividing resistor (8), a relay coil (2), a fuse (4), the negative pole of the second ground connection (5), and the ground connection (5) ) is set at the upper limit point (A) of the water level, and the positive pole of the second ground connection (5) is connected in series with the normally closed button (12) and the rear end point of the normally open contact (6) of the relay is set at the lower limit point of the water level (B ) place. The voltage stabilizing tube (3) is connected in parallel with both ends of the relay coil (2), and is used to stabilize the input voltage of the relay coil (2) and doubles as a freewheeling tube. The three power lines of the water pump motor (13) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com