Heat pipe heat transfer performance test device and testing method thereof

A technology of heat transfer performance and test method, applied in the field of heat transfer, can solve the problems of error, mass flow error of cooling medium, large total error, etc., and achieve the effects of convenient testing, high testing accuracy and simple testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

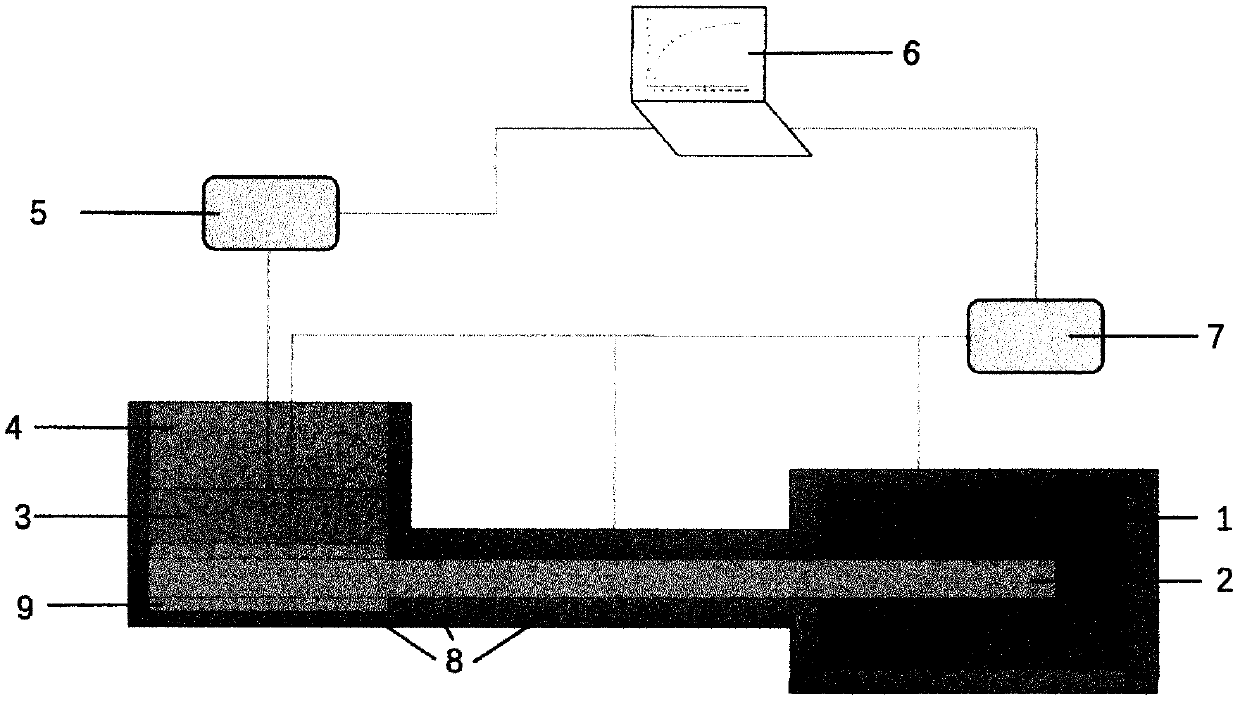

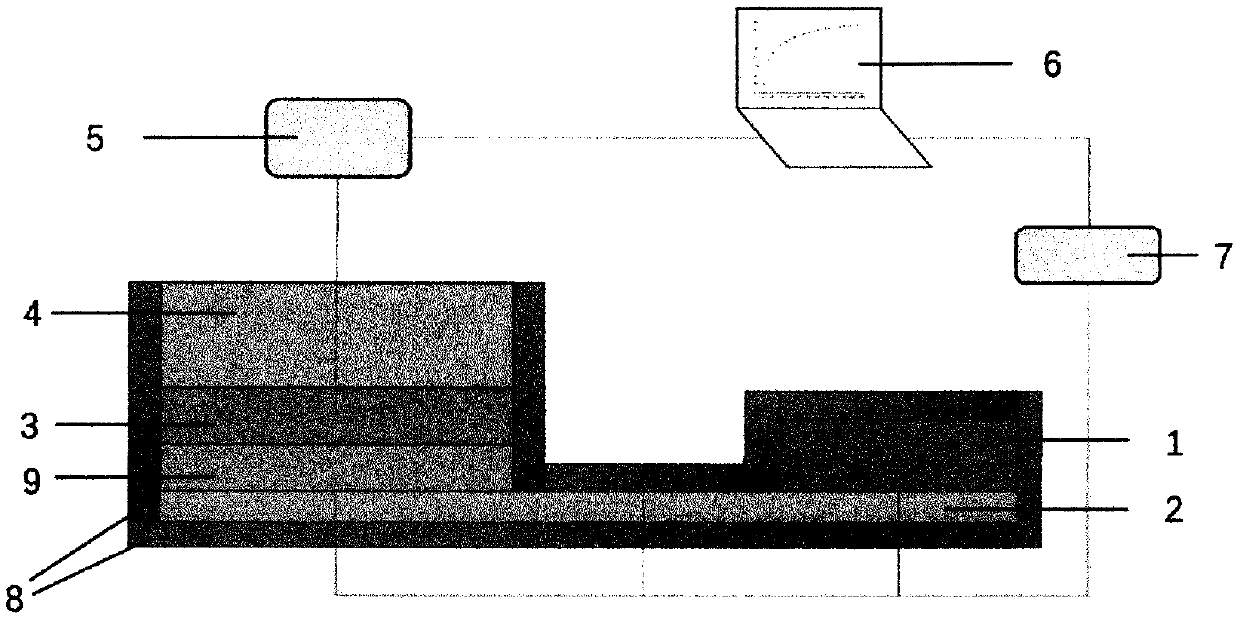

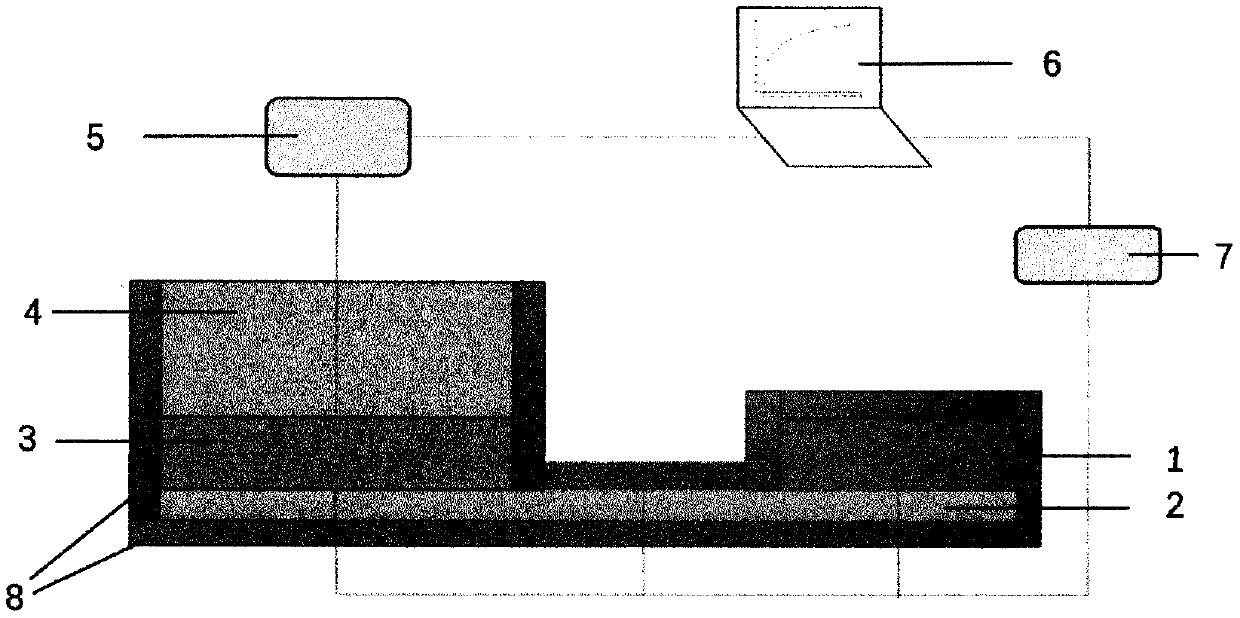

[0041] Such as figure 1 As shown, the present invention provides a novel heat pipe heat transfer performance testing device and a testing method thereof. A heat pipe heat transfer performance testing device includes a heating device 1, a heat pipe to be tested 2, a thermoelectric conversion module 3, a cold source system 4, An electrical parameter measurement system 5 , an electronic computer 6 , a temperature measurement system 7 , an insulating material 8 and a transition module 9 . During the test, the heat is first transferred from the heating equipment to the evaporation section of the heat pipe to be tested, then transferred from the evaporation section of the heat pipe to the adiabatic section and the condensation section, and then transferred from the condensation section to the transition module and the thermoelectric conversion module, through the electrical parameter measurement system and The electronic computer measures the real-time conversion of the thermoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com