Monitoring structure and monitoring method for width of large-size opening of silicon wet etching tank

A technology of wet etching and opening width, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of inaccurate measurement, large measurement error of large size, etc., and achieve the advantages of convenient operation, low cost and high monitoring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: In this case, it is a method for monitoring the large-scale opening width of a silicon wet etching tank, which includes the following steps: step S1, making a photolithographic plate mask; step S2, photolithography and etching to form a rectangular window to be etched; step S3, Wet etching; step S4, corrosion monitoring;

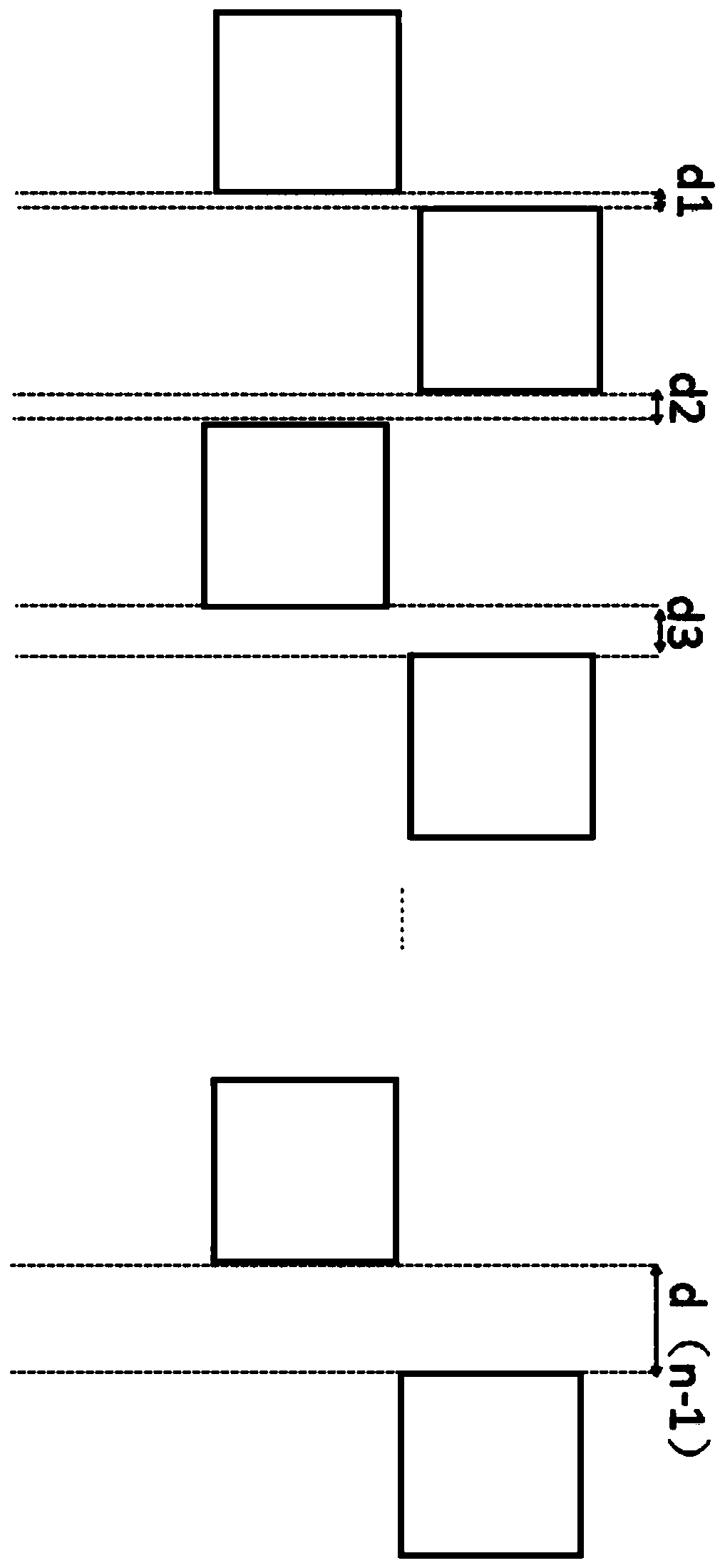

[0026] One: Add monitoring graphics in the layout, the monitoring graphics include: n rectangular windows for wet etching, and open n rectangular windows in the layout to facilitate subsequent etching;

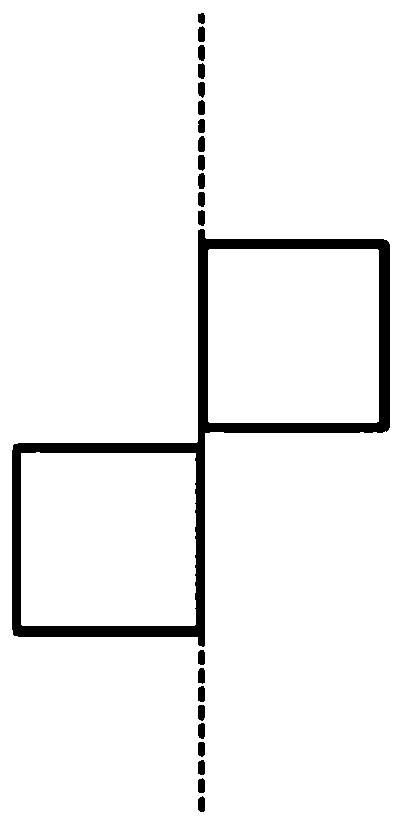

[0027] Two: The monitoring graphics are arranged in dislocation, and the dislocation spacing is arranged in increasing order from 1um to (n-1)um, d1=1um, d2=2um, d3=3um...d(n-1)=(n-1 )um;

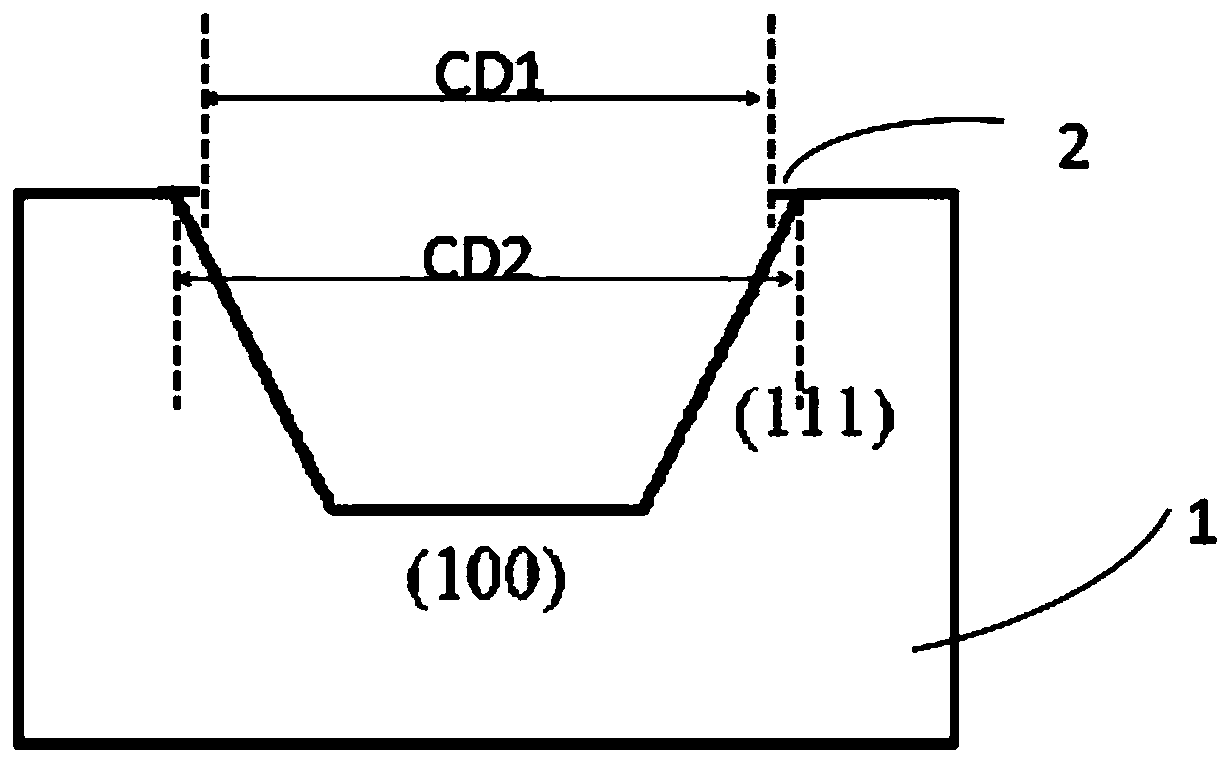

[0028] Three: Perform anisotropic wet etching on the bottom of the single crystal silicon according to the layout with monitoring graphics, form the wet etching groove that needs to be monitored on the single crystal silicon material and use it to moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com