High-heat-dissipation-performance tin soldering paste for low-temperature sintering technology and preparation method thereof

A low-temperature sintering and solder paste technology, used in welding equipment, metal processing equipment, welding media, etc., can solve problems affecting product service life, high welding temperature, device damage, etc., to reduce thermal load, improve service life and reliability. the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

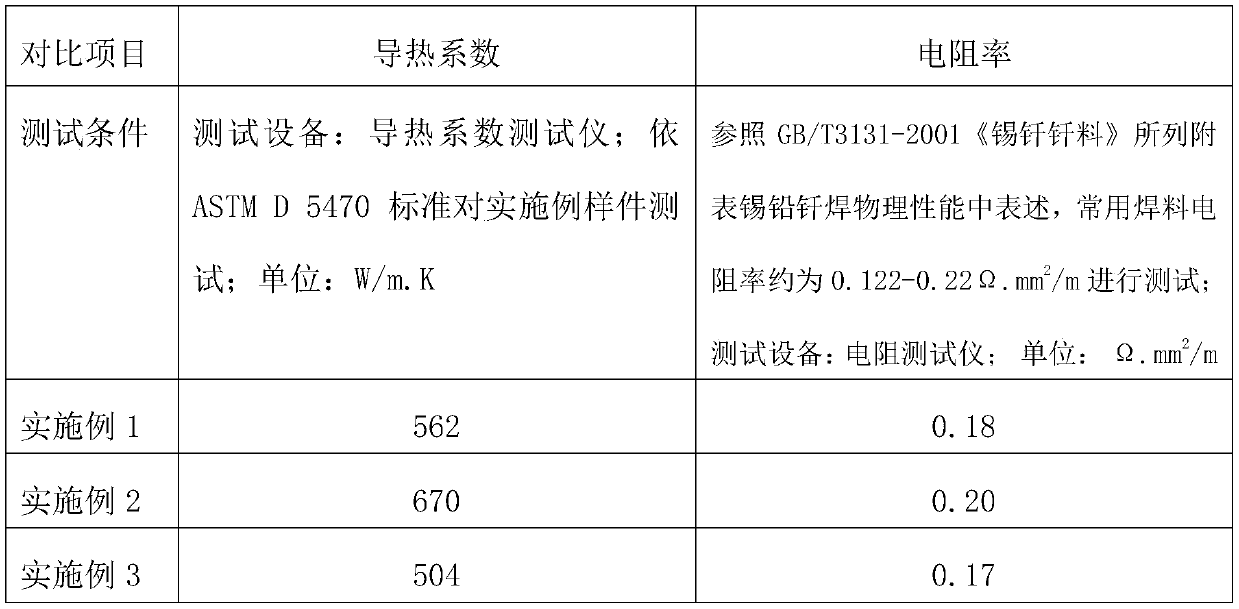

Examples

Embodiment 1

[0037] A kind of solder paste with ultra-high heat dissipation performance suitable for low-temperature sintering process and the preparation of test samples are carried out according to the following steps:

[0038] Step 1, prepare component (1) filler: stearic acid amide 4.2Kg, super rosin 10.8Kg, and component (2) dispersant: dioctyl ether 5.0Kg, tetrahydrofurfuryl alcohol 2.5Kg, adipic acid 3.0Kg , ethyl acetate 4.0Kg, high-efficiency surfactant (FT900) 0.5Kg, the above materials are mixed and heated to 110-130 ° C, after the solid materials are all melted, the mixture is stirred and mixed for about 30 minutes to obtain a paste auxiliary agent;

[0039] Step 2, prepare component (3) metal powder: 6337 tin-lead powder (tin 63%, lead 37%) 57Kg, pure silver powder 3.0Kg, pure bismuth powder 6.8Kg, and component (4) diamond powder: diamond powder ( Polycrystalline powder, particle size 1-3 microns, median value 2 microns) 3.2Kg, added to the paste additive prepared in the abo...

Embodiment 2

[0043] A kind of solder paste with ultra-high heat dissipation performance suitable for low-temperature sintering process and the preparation of test samples are carried out according to the following steps:

[0044] Step 1, prepare component (1) filler and component (2) dispersant: stearic acid amide 3.6Kg, super rosin 11.5Kg, dioctyl ether 4.0Kg, tetrahydrofurfuryl alcohol 2.0Kg, adipic acid 3.0Kg, Ethyl acetate 3.2Kg, high-efficiency surfactant (FT900) 0.8Kg, mix the above materials and heat to 110-130°C, after all the solid materials are melted, stir and mix for about 30 minutes to obtain a paste additive ;

[0045] Step 2, prepare component (3) metal powder and component (4) diamond powder: 6337 tin-lead powder (tin 63%, lead 37%) 55Kg, pure silver powder 3.0Kg, pure bismuth powder 6.8Kg, diamond powder (multiple Crystal powder, particle size 1-3 microns, median value 2 microns) 7.1Kg, added to the paste additive prepared in the above step 1 and returned to room temperat...

Embodiment 3

[0049] A kind of solder paste with ultra-high heat dissipation performance suitable for low-temperature sintering process and the preparation of test samples are carried out according to the following steps:

[0050] Step 1, prepare component (1) filler and component (2) dispersant: stearic acid amide 2.5Kg, super rosin 12.0Kg, dioctyl ether 3.0Kg, tetrahydrofurfuryl alcohol 1.5Kg, adipic acid 3.0Kg, Ethyl acetate 3.6Kg, high-efficiency surfactant (FT900) 0.6Kg, mix the above materials and heat to 110-130°C, after all the solid materials are melted, stir and mix for about 30 minutes to obtain a paste additive ;

[0051] Step 2, prepare component (3) metal powder and component (4) diamond powder: 6337 tin-lead powder (tin 63%, lead 37%) 60Kg, pure silver powder 3.0Kg, pure bismuth powder 6.8Kg, diamond powder (multiple Crystal powder, particle size 1-3 microns, median value 2 microns) 4.0Kg, added to the paste additive prepared in the above step 1 and returned to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com