Metal debris treatment device for machining

A metal scrap and processing device technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of large labor, inconvenient operation, loose structure, etc., and achieve high processing efficiency, convenient operation, labor small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

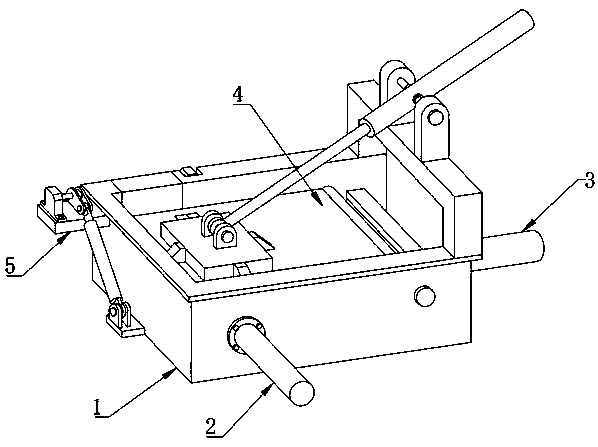

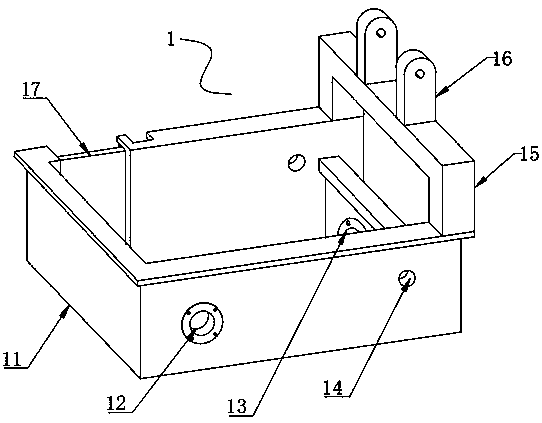

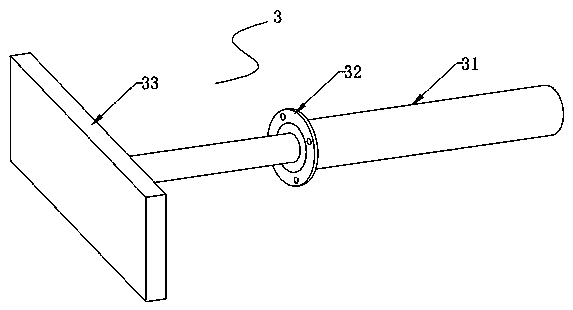

[0022] see Figure 1~5 , in an embodiment of the present invention, a metal scrap processing device for mechanical processing includes a compression box 1, a turning mechanism 5 is installed on one side of the compression box 1, and a vertical Compression mechanism 3, the front end of compression box 1 is embedded with transverse compression mechanism 2, and the inner side of the upper end of compression box 1 is connected with sealing mechanism 4, and compression box 1 includes box body 11, and one end of the inside of box body 11 is provided with second Mounting holes 13, the front and rear sides of the casing 11 are provided with shaft holes 14 near the end of the second mounting holes 13, and the top of the casing 11 is fixedly connected with a door frame 15 near the other side of the second mounting holes 13, and the casing 11 There is a first installation hole 12 on the side away from the second installation hole 13 at the front end of the box body 11, and a flip card sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com