Multifunctional aerated concrete curing table

A kind of air-entrained concrete, multi-functional technology, applied in the direction of ceramic molding machine, auxiliary molding equipment, general water supply saving, etc., can solve the problems of labor cost increase, easy problems, water quality deodorization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

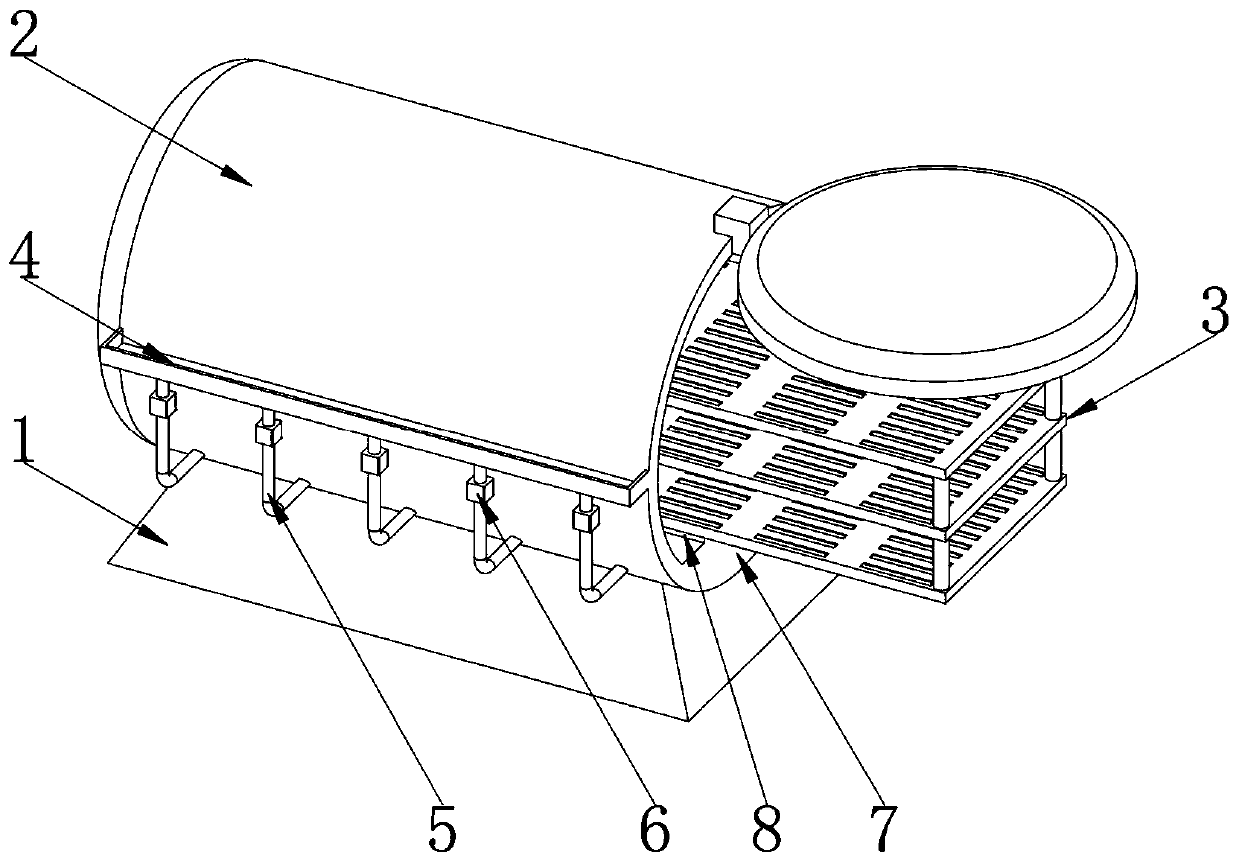

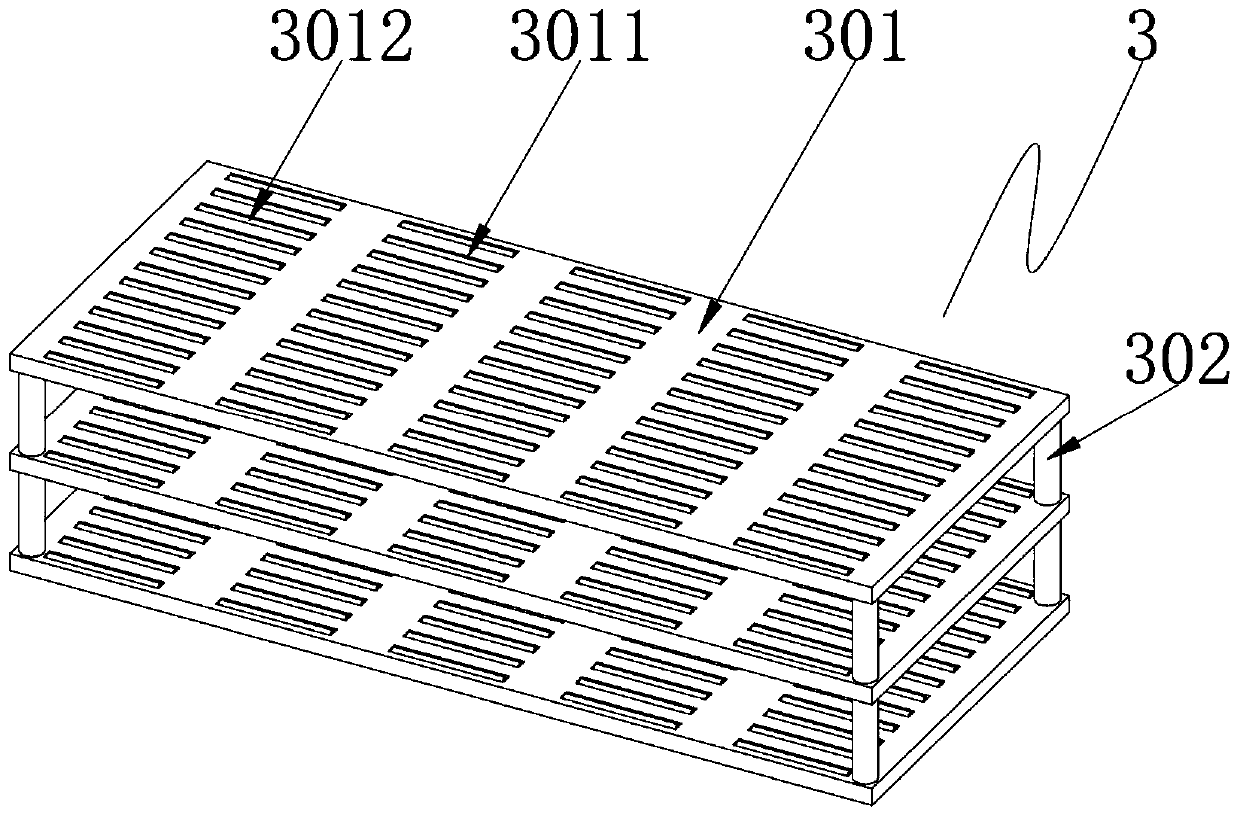

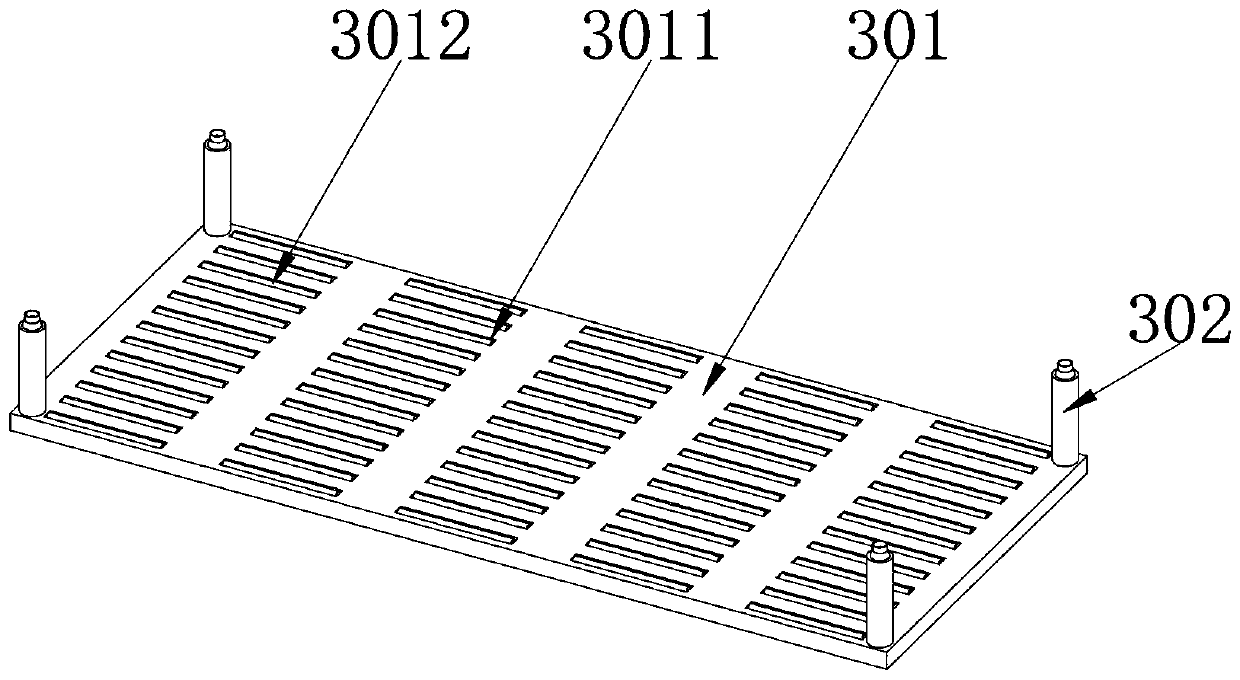

[0044] Example: such as Figure 1-10 As shown, a multifunctional aerated concrete curing platform includes a base 1, a curing tank 2 and a curing platform 3;

[0045] A curing tank 2 is arranged above the base 1. The curing tank 2 is used to provide an environment for the curing of the aerated concrete. A curing platform 3 is placed inside the curing tank 2. The curing platform 3 is used for placing and curing the aerated concrete blocks. Both sides of the maintenance tank 2 are equipped with rainwater collection tanks 4, which are used to collect rainwater when it rains. The arc-shaped setting at the top of the maintenance tank 2 can collect rainwater to the greatest extent, and maintain A water storage tank 7 is provided at the bottom of the tank 2, and the water storage tank 7 is used to store the collected rainwater. The rainwater collection tank 4 and the water storage tank 7 are connected by a delivery pipe 5, and a filter box 6 is provided in the middle of the delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com