Method for purifying coking concentrated ammonia water

A technology for concentrated ammonia water and ammonia distillation wastewater, which is applied in chemical instruments and methods, ammonia preparation/separation, ammonia compounds, etc., can solve the problems of difficulty in regeneration, large amount of activated carbon, and no disclosure of purification of coking concentrated ammonia water. The effect of saving investment, simple and reliable regeneration operation, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

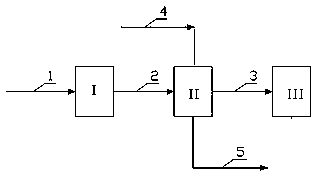

[0038] The specific implementation is as figure 1 In the shown device process, the impurity-containing coking concentrated ammonia water from the coking ammonia distillation section has a tar concentration of 181 mg / L and a naphthalene content of 3000 mg / L, and is sent into an adsorption tower filled with adsorbent, wherein the The adsorbent is a molecular sieve adsorbent, and the adsorbent is a hydrophobic ZSM-5 molecular sieve. The tar content in the coking concentrated ammonia water after adsorption is 2.2 mg / L, and the naphthalene content is 150 mg / L, which will be used in the subsequent denitrification section.

Embodiment 2

[0040] The specific implementation is as figure 1 As shown in the device process, the impurity-containing coking concentrated ammonia water from the coking ammonia distillation section contains a tar concentration of 200mg / L and a naphthalene content of 2000 mg / L, and is sent to the pretreatment tower, and the pretreated coking concentrated ammonia water is sent to the filling An adsorption tower with an adsorbent, wherein the adsorbent is a molecular sieve adsorbent, the adsorbent adopts TS-1 type molecular sieve, the tar content in the coking concentrated ammonia water after adsorption is 3 mg / L, and the naphthalene content is 100 mg / L. Subsequent use section.

Embodiment 3

[0042] The specific implementation is as figure 1 As shown in the device process, the impurity-containing coking concentrated ammonia water from the coking ammonia distillation section contains a tar concentration of 220 mg / L and a naphthalene content of 2000 mg / L, and is sent to the pretreatment tower, and the pretreated coking concentrated ammonia water is sent to the filling An adsorption tower with an adsorbent, wherein the adsorbent is a molecular sieve adsorbent, the adsorbent adopts TS-1 type molecular sieve, the tar content in the coking concentrated ammonia water after adsorption is 1 mg / L, and the naphthalene content is 100mg / L, enter Subsequent use section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com