Temperature control fracturing fluid

A fracturing fluid and temperature control technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve good high temperature resistance, damage reduction, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

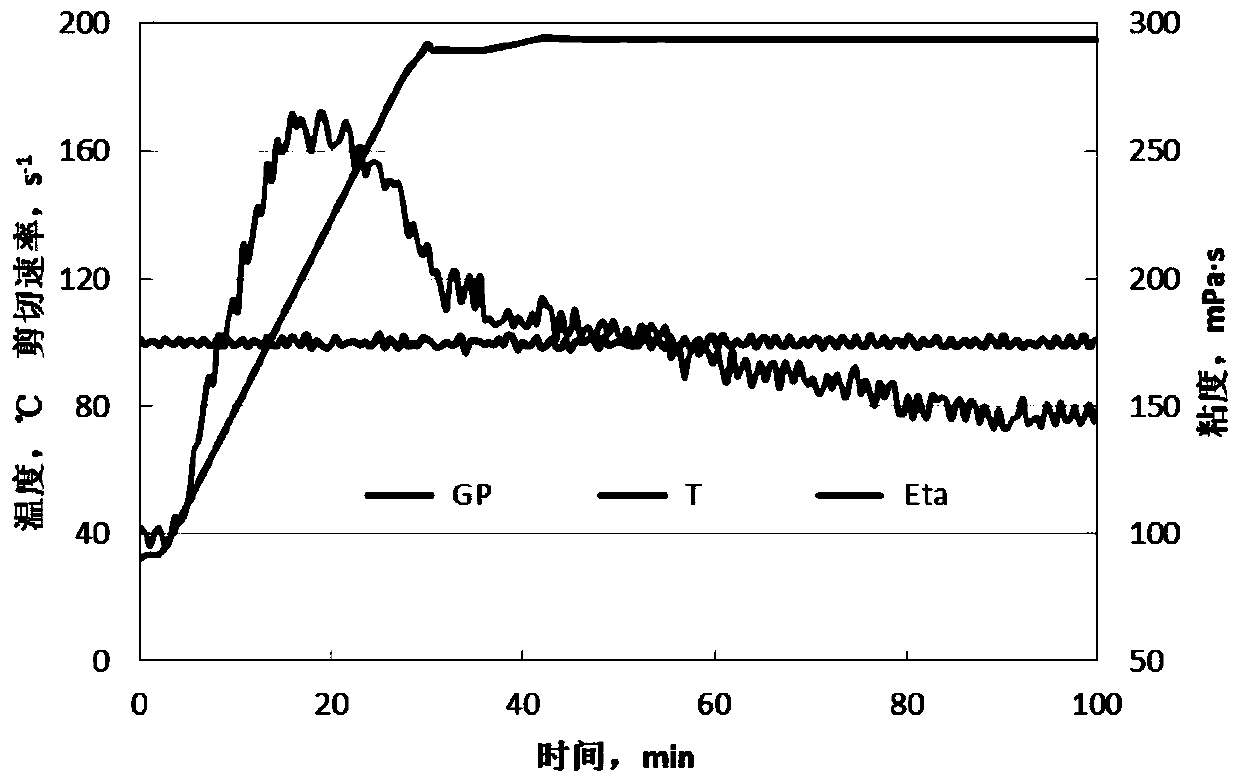

Embodiment 1

[0066] The preparation of embodiment 1 temperature control cross-linking agent

[0067] Mix zirconium tetrachloride, boric acid, glycerin, lactic acid and triethanolamine in water at a mass ratio of 1:2.5:2.5:2:3 and then heat to react to obtain a temperature-controlled crosslinking agent; the heating temperature is 60°C , the time is 6 hours; the temperature of the reaction is 100° C., and the reaction time is 1 hour.

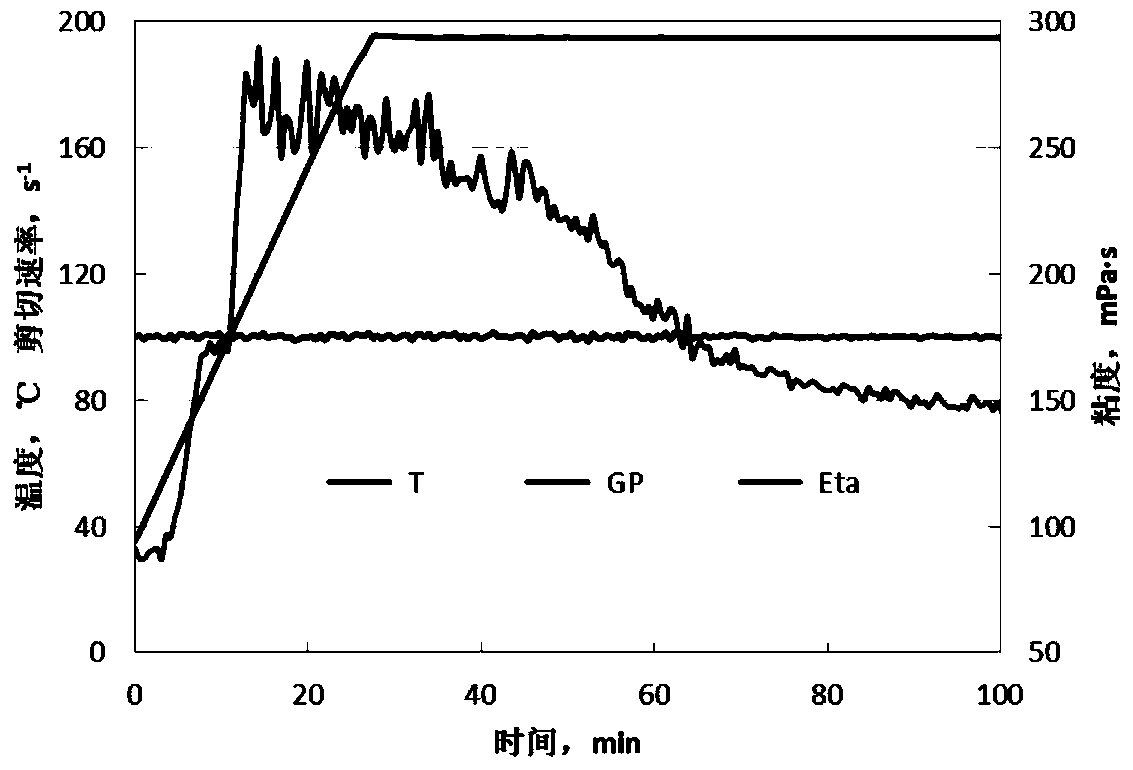

Embodiment 2

[0068] Embodiment 2 Preparation of temperature-controlled crosslinking agent

[0069] Zirconium acetate, borax, glycerin, lactic acid and triethanolamine are mixed in water at a mass ratio of 1:2:3:3:3.5 and then heated for reaction to obtain a temperature-controlled crosslinking agent; the heating temperature is 75°C, and the time was 7 hours; the temperature of the reaction was 110° C., and the reaction time was 2 hours.

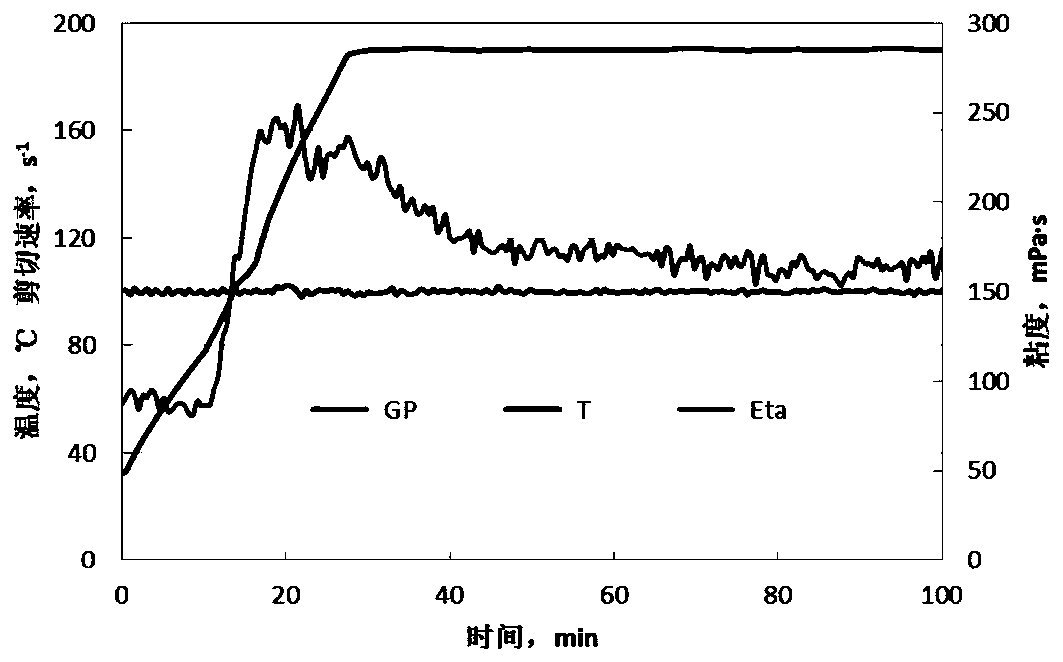

Embodiment 3

[0070] Embodiment 3 Preparation of temperature-controlled crosslinking agent

[0071] Mix zirconium nitrate, boric acid, glycerin, lactic acid and triethanolamine in water at a mass ratio of 1:3:3.5:4:5 and then heat to react to obtain a temperature-controlled crosslinking agent; the heating temperature is 80°C, and the time is was 7 hours; the temperature of the reaction was 120° C., and the reaction time was 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com